Sound insulation wool: technical characteristics of materials

Insulation and soundproofing of the building is one of the most difficult stages of construction. The use of insulating materials greatly simplifies this process. However, the question of their choice of materials remains relevant - it is necessary to choose a suitable product, to mount it correctly.

Peculiarities

Sound insulation wool, more commonly known as mineral wool, is a material used to reduce the noise level entering a room. This material should not be confused with a sound-absorbing analogue, which absorbs noise inside the room, preventing it from spreading outside the room.

The basis of wadded insulation is long and flexible inorganic fibers obtained from quartz, basalt, limestone or dolomite.

The production process involves melting the stone base, after which fibers are drawn from it, which are then formed into threads.

Soundproof sheets are formed from the threads, and the material is characterized by a chaotic arrangement of fibers. Numerous air "windows" are formed between them, due to which the soundproofing effect is achieved.

Wadded materials for sound insulation have the following technical properties:

- low thermal conductivity, which allows the use of cotton wool also as insulation;

- fire resistancedue to the stone base of the material;

- strength - we are talking about high strength characteristics not of a single fiber, but of a cotton sheet;

- deformation resistance, including when the material is compressed, heated or cooled;

- hydrophobicity, that is, the ability to repel water particles;

- durability - the service life of wadded soundproofing materials is on average 50 years.

Scope of application

Mineral wool today is characterized by a wide range of applications. The material is actively used for insulation of surfaces exposed to heating, walls and ceilings, fire protection of various structures, as well as for noise insulation of residential and non-residential, including industrial premises.

The following areas of use of cotton sound insulators are distinguished:

- insulation of the outer part of plaster and hinged buildings;

- insulation of the interior of buildings - walls, ceiling, floor in an apartment, private house, as well as in household buildings;

- insulation of multilayer enclosing structures;

- insulation of industrial equipment, engineering structures, pipelines;

- insulation of roof structures.

Views

Depending on the composition, properties and scope of application, there are 3 main types of wool for sound insulation:

Material

Basalt

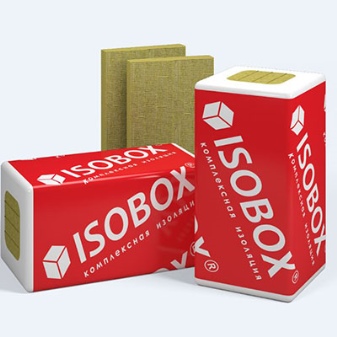

The material is based on basalt, which is distinguished by its strength. This determines the best indicators of sound and heat insulation of the finished product, the ability to withstand heating while maintaining technical properties up to a temperature of +600 degrees.

For the manufacture of basalt wool, fibers with a length of 16 mm are used. Their diameter does not exceed 12 microns. Unlike slag and glass, this type of mineral wool is environmentally friendly, it is convenient to cut it, when used during installation, it does not prick.

Glass

Glass wool is a product of glass and limestone processing, to which sand and soda are added.The result is a strong and resilient material, which, however, has less fire resistance. The maximum heating temperature is 500 degrees. The material is very fragile and prickly. Release form - rolls.

Rolled glass wool is well known even to people far from construction. If the rules for safe installation are not followed, thin and long (up to 50 mm) threads of the material instantly dig into the skin. That is why the installation of glass wool should be done only in overalls, protecting hands and eyes.

Slag

The basis of the material is blast furnace slags, which are characterized by residual acidity. In this regard, even a small amount of water that gets on the insulation, provided that it is laid on top of the metal, provokes the emergence of an aggressive environment.

Characterized by increased hygroscopicity, slag wool is not used to insulate facades and pipelines. The maximum possible heating of the material does not exceed 300 degrees.

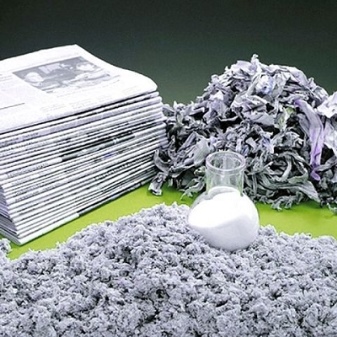

Ecowool

It is a material made up of 80% recycled cellulose. Initially, the building was insulated with ecowool, but it was quickly discovered that it was also suitable for sound insulation. In terms of its thermal insulation properties, it is not inferior to foam, however, rigid polystyrene plates are not suitable for insulating pipes and other complex structures.

Installation of ecowool requires special equipment, in addition, it is flammable and capable of accumulating moisture.

Density

Depending on the density indicators, the following types of cotton wool are distinguished:

Easy

Density indicators - up to 90 kg / m³. Serves for heat and sound insulation, mounted in places that are not subject to stress. An example of this type of materials is the P-75 soundproofing mineral wool with a density of 75 kg / m³. It is suitable for thermal insulation and sound insulation of attics and roofs, heating system pipelines, gas pipelines.

Hard

It is characterized by a density of more than 90 kg / m³, during use it can be subjected to some load (its degree is determined by the density of the cotton wool). Hard wool P-125, used to insulate walls and ceilings of buildings, internal partitions of premises, is referred to as rigid.

Technical

It is used for insulation of industrial equipment, capable of withstanding significant loads. For example, mineral wool PPZh-200 is used in the isolation of engineering structures, serves to increase the fire resistance of structures.

Release form

Depending on the form of release, mineral wool products are of the following types.

Mats

Convenient for use on a large area for installation in suspended ceilings, partitions. For ease of transportation and storage, the material is produced in a compressed form, and after opening the package, it acquires the declared parameters. The disadvantage is the difficulty in cutting into small pieces.

Slabs

Tiled products are distinguished by good noise insulation properties (especially when absorbing "air" noise), easy to install. It is used to insulate roof slopes, walls, ceilings. Density indicators usually do not exceed 30 kg / m³

Rigid slabs

Such material in slabs is recommended for absorbing "impact" noise. They are easy to install, easy to cut. An important requirement is the laying of a vapor barrier layer between the insulating material and the floor.

Rolls

Material of small to medium hardness is usually rolled into rolls. Due to this shape, it is convenient and easy to transport, the user has the ability to cut layers of material of the desired length. The width of the material is standard and is usually 1 m.

Finally, there are acoustic wool, which has a foil layer on one side. Sound insulation with foil-clad material is effective, but suitable for external parts of buildings or when carefully insulating the material with foil.

Material with foil does not require additional waterproofing, in addition, its thermal insulation properties are increased due to the ability to reflect thermal radiation.

The form of release of the foil insulator is rolls and slabs of basalt wool or fiberglass with foil applied on one side. The thickness of the material is 5-10 cm.

Together with the density indicators of mineral wool, its values of thermal efficiency, fire resistance, and ability to sound insulation are growing.

How to choose?

- One of the most important selection criteria is the density of the cotton wool. The higher this indicator, the higher the cost of mineral wool, which is due to the high consumption of raw materials.

- When buying mineral wool of a certain density, it is worth considering its purpose. If it is necessary to increase the sound insulation and insulation of the facade and other elements of a private house, preference should be given to the medium density option (50-70 90 kg / m³).

- Stone wool is considered the best option - it is an environmentally friendly and fire-resistant material that is convenient to work with. In terms of its technical characteristics, it surpasses glass wool and slag analogue, however, the cost is also higher.

- If it is necessary to isolate an irregularly shaped structure, it is more convenient to use more plastic glass wool with a low or medium density (the lower the density, the softer the material, which means that it is easier to fit on a surface of a complex shape). However, during operation, it shrinks, which is important to consider during installation.

- If the thermal insulation properties of cotton wool are no less important than the soundproof ones, choose cotton wool with a chaotic arrangement of fibers. Such material, in comparison with vertically oriented counterparts, contains more air bubbles, which means that its thermal efficiency indicators are higher.

- An important parameter is the vapor permeability of the material, that is, its ability to pass moisture vapor without accumulating liquid inside the material. The value of vapor permeability is especially important when insulating walls of residential buildings, primarily wooden ones. Stone wool is the best at vapor barrier.

- In production, polymers and other substances are used as binding elements. It is important that they do not contain formaldehyde resins. In this case, the toxicity of the material is undeniable.

- As with the purchase of any building materials, when choosing mineral wool, you should stop your choice on products of well-known brands. The trust of buyers has earned the products of German production. Brands such as Isover, Ursa, Rockwool have positive reviews.

How to use it correctly?

When laying mineral wool insulation with your own hands, first of all, you should take care of protecting the upper respiratory tract and skin. All materials under consideration tend to irritate the mucous membranes of the upper respiratory tract to a greater or lesser extent.

One of the most important rules for sound insulation is absolute tightness. All joints between materials must be sealed with silicone sealant. The use of polyurethane foam is not recommended, as this will not allow to achieve tightness.

The most common form of soundproofing premises is the installation of plasterboard structures with mineral wool materials inside. First of all, you should plaster the surfaces. This will not only eliminate defects, but also increase the sound insulation of the room.

Further, special brackets and profiles are installed on the walls, onto which drywall sheets are attached. Insulation layers are laid between them and the wall.

An important point - the frame must be arranged in such a way that there is an air gasket between the drywall and the wall. The effectiveness of sound insulation depends on its presence and thickness.

Keep in mind that sockets and pipe entry points into walls are also sources of noise. They also need to be soundproofed, and the seams must be filled with silicone sealant.

In the next video you will see the installation of TECHNOACUSTIK sound insulation from TechnoNICOL.

Thanks for the clear presentation.

The comment was sent successfully.