How to install a rivet?

Most things have different fasteners. The most popular type is the rivet. Sometimes such a part becomes unusable, so they get a new one. Replacing it turns out to be much more difficult, since the question arises as to how to correctly install the rivet.

It is almost impossible to solve the problem manually; it is necessary to use a special unit. Below we will understand in more detail what is the peculiarity of the installation and how to choose the most suitable technique.

Installation features

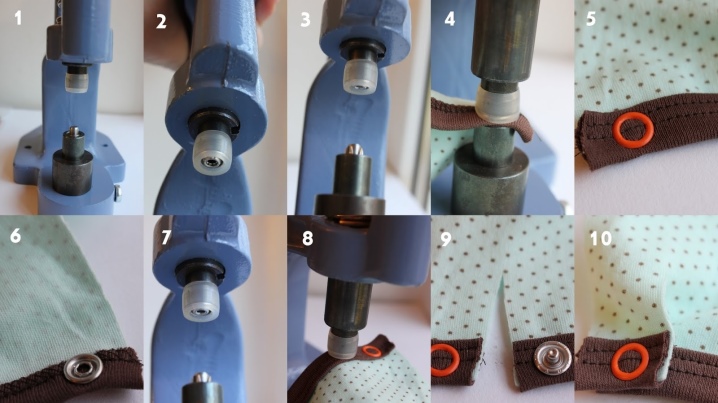

To install a rivet, you need to follow a simple instruction. Let's take a closer look at the steps.

- Parts must have pre-drilled holes. They are connected to each other, the rivet body in the form of a cylinder is placed there.

- The rod is located all over the body, it must be grasped with sponges (sometimes a riveting head at a riveting tool is suitable for this purpose). It should be borne in mind that the seizure takes place near the base of the cylinder head.

- Next, you need to make a little effort and pull the rod through the rivet body. The process is accompanied by the expansion of the cap or head. By changing the end of the cylinder, it is possible to form the opposite wide part of the rivet (it is located on the surface of the previously connected parts).

- After we have managed to install the parts, the remnants of the elongated rod should be broken off exactly at the moment when the riveter's force is at its limit. It is advisable to immediately check if the connection is strong enough.

If you work with a manual riveter, then the process must be performed several times, and at the same time press the lever so that the desired result is achieved.

After the action is completed, on one side of the joint it will be possible to find the head from the rivet body, and on the other side there will be a flattened end from the cylinder, which should resemble petals in appearance.

What do you need?

In order to manufacture the body of the future rivet, various materials are required. For the production of rods, only hard metal is used - steel.

When choosing rivets, attention is usually paid to their characteristics. Should be interested in strength, and how one part affects another. For durability, it is recommended to select rivets in such a way that their type and material match each other.

Experts additionally advise to take a closer look at the rivet length. If the part turns out to be less than the thickness of the elements to be connected, then there may simply not be enough material to create the closing head.

If the size is too large, the cover head will overlap the limits of the parts.

There are a variety of rivets on the market. Each of them has its own advantages.

- Classic ones are usually used for most types of fastening.

- With the help of threaded connections, reliable connections are created. This is especially true for parts that have thin walls. Usually such a part is characterized by a countersunk or wide flange. The thread is located on the inside. On the outside there is a corrugation, it affects the increase in the strength of the fit.

- Piston ones are distinguished by the fact that at the end of the rivet there is a stamped conical recess. For the manufacture of the part itself, it is recommended to use exclusively soft metals. When the elements are connected, two hats are obtained.

- The rod contains a solid rod. It helps to withstand strong physical activity.

- If traction is used, then when riveting, they will not need to be held.

- Tubular ones have a kind of cavity inside the part. This type is most often used at low loads.

The riveter is a special tool, in another way it is called "pliers". It works by analogy with a pistol and is necessary in order to connect structural elements, as well as individual parts. The main condition is that the thickness of the product should not exceed 10 mm.

The power gun helps to fix the parts from their inside. The hand riveter has 2 parts. The first is the spring mechanism. Its main task boils down to the fact that it helps to pull such a rivet inside. The second is a leverage system that requires additional effort to apply.

The most popular riveting tool options are pull-out and threaded rivets.

If a rivet is to be secured, pulling force must be applied. The most suitable option is a pull-out type of a hand riveter. The rivet shank is pulled in by applying force against the lever. The head of the rod seems to expand. In order for the parts to be firmly fixed, the elements from the outside must be flattened.

The work of the threaded riveter is practically the same. It is necessary to remember the main rule - the ball is drawn into the working part, after which such a part is twisted properly. No extra effort is needed here. It is worth resorting to twisting the handle only if there is a need to fix a part that is small in its thickness.

Additionally, nozzles can be found in specialized stores complete with a gun. They mainly differ in diameter and tail length.

How to rivet?

Before using the manual riveter, it is recommended that you understand the hardware design. It is for this method of fastening that rivets are intended.

- The cylinder has a hole, it runs along the entire body, while also capturing the head area. Externally, the metal rod bears resemblance to a nail that has a rounded head. To insert into a cylindrical hole, we need a retainer. Then the head is retracted until it stops.

- The rivet helps to fasten. It consists of a metal rod and a cylindrical tube - these are 2 main elements. There is always a head at the end of the tube.

- Threaded rivets are relevant for pull-out hand rivets. It is important to take into account that the rod has its own thread. It scrolls exactly to the point that the cylinder is inserted.

To make the connection as strong as possible, a screw is screwed onto the metal. Additionally, the details can be taken under the hammer. When choosing the diameter of a cylindrical body, it is best to immediately measure the holes for the fastener.

Next, we will figure out step by step how to properly fix aluminum and tubular parts with our own hands and carry out their installation. In order to attach rivets at home, a special tool is required. He is called a riveter.

There are 2 types of riveters - amateur and professional. Each of the tools has interchangeable heads. They are needed when working with elements of different sizes that are used during fastening. The main difference is the price and the force required to push.

To rivet parts correctly, you need to adhere to the following algorithm:

- we apply markings to the parts that we plan to connect;

- we drill the necessary holes with a drill;

- then you need to insert a rivet;

- the riveter's handles move apart, a rod is inserted into it;

- then the handles must be squeezed until the rod breaks off;

- we loosen the handles and check if the rod has completely entered.

Almost any metal can be used to make a fume product.It is necessary to approach the choice of material in such a way that there is no subsequent corrosion process.

When creating a rod, it is customary to use a steel base. It is characterized by high strength. Various options are allowed in the size and length of the cylinder, it all depends on what is the ultimate purpose of such a product. Before making a purchase, it is recommended to think over exactly what characteristics will be required.

How to install a rivet, see below.

The comment was sent successfully.