How to calculate the distance from the hood to the stove?

The exhaust device is a necessary element of the kitchen. It is used for room ventilation. When the cooking process is in progress, food can burn, and then unpleasant odors appear. It will not be difficult to remove them using modern technology.

If you decide to get a hood, it will be important to correctly calculate the distance from it to the stove so that odors are removed as efficiently as possible.

Standards

To ensure the required air purity in the room, comfortable for a person, ventilation must be installed in accordance with all accepted norms and standards. For different types of plates, there are two types of hoods: inclined and regular (straight). The recommended distance from the hood to the stove directly depends on the type of kitchen panel and the design features of the equipment for a particular kitchen.

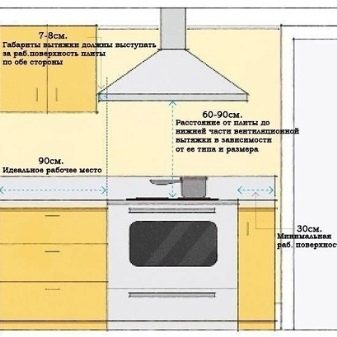

The minimum distance above the countertop of a gas stove for a conventional hood is seventy-five centimeters, above an electric stove - sixty-five centimeters. If we consider an inclined hood, then the indicators will be fifty-five centimeters for gas and thirty-five centimeters for inclined ventilation.

The distance rate is chosen by the person who will cook, therefore it may also depend on the owner's height, the type of kitchen, the height of the ceilings.

It is allowed to change the height of the hood by 5-10 centimeters from the minimum distance. The correct choice of the distance between the cooker hood and the stove top affects the efficiency of work, safety of operation and the long-term use of this household appliance. After all, improper installation of the device below the required level entails heating and, consequently, the failure of the unit.

By type of construction, hoods are divided into three types:

- flowing;

- circulating;

- mixed.

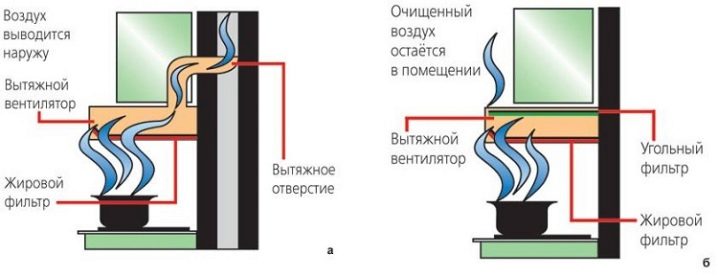

The process of operating the air intakes of the flow-through structure is as follows. The duct pipes are connected to the general ventilation system of the house, the polluted air goes through the pipes to the general ventilation, and clean and pleasant air enters the room where food is prepared through open doors and windows. Circulation models are not connected to the general house system, in them the air is cleaned in the internal filter system of the unit and returns to the kitchen.

A high-performance motor is installed on this device, which increases the efficiency of the unit. Such structures are usually installed in old houses or in kitchens, where the worktop of the hob is located at a distance from the ventilation duct.

Mixed exhaust units have the design features of the previous types; they have an air duct that works in conjunction with an air filtration system. This ventilation system is convenient to use in winter to keep the kitchen and apartment warm. The disadvantage of such an air intake is that when the device is turned off, due to its design, it blocks ventilation. Therefore, there is a forced need to open windows for ventilation. Also, the installation, due to the powerful motor, is very noisy when used, the same applies to circulation models.

How does the size of the equipment affect?

The dimensions of the ventilation of the kitchen are different, it is worth considering this when choosing a hood.It should be installed after measuring the kitchen itself.

Necessary:

- calculate the size of the room;

- determine the position of interior items in the kitchen;

- measure the dimensions of the plate;

- take into account the height of everyone living in the apartment;

- select the desired type of ventilation and efficiency;

- consider where the device will be installed.

Built-in hoods are installed directly above a gas or electric stove to ensure maximum efficiency. Such models are located inside the kitchen interior object.

Such a ventilation system is invisible in the kitchen; only the surface into which the air enters can be visually seen. Of the various types of built-in ventilation, telescopic ones are especially popular. These hoods have a powerful motor with a maximum capacity of 1000 cubic meters. m / hour. To install models of this type, you will need a wall cabinet without a bottom. The dimensions of the cabinet and ventilation must match.

When installing the duct, it is recommended to avoid unnecessary bends in the pipe to avoid power loss. It is necessary to install exhaust ventilation check valves so that polluted air does not get back into the room. Installation of this type of hood begins with the assembly of the cabinet or box. The box is made of wood. The assembly of the box is carried out as follows: the top of the box and its side parts are fastened immediately, and after that the dimensions of the box and the hood are compared. Then the lower part of the cabinet is mounted, where the hole for the air duct is cut. For quiet operation, it is recommended to use plastic air ducts.

What to consider when installing?

If you have a compact cooking room, then by purchasing a voluminous ventilation structure, you risk creating inconvenience for yourself and your family. In this case, it will be advisable to take a built-in hood and install it in a cabinet on the wall, if it is above the hob or in another element of the kitchen interior. The main thing is that it is located above the stove top. The air intake should be sized to match the size of the plate over which it will be installed. If the dimensions are smaller, then the air intake will not take place completely, therefore, the air will not be cleared. But if the air intake device is slightly larger than the stove, then it's okay, it's even better.

Dimensions and characteristics affect the height of the hood above the hob. Low power systems should be installed at a height of at least seventy-five centimeters. If the air intake capacity exceeds five hundred and fifty cubic meters. m / hour, then the distance from the cooking surface to the edge of the device should be increased.

The angle of inclination of the ventilation will also affect the height above the stove. If it is equal to zero, then no changes in height need to be made. But if an angle appears, then the distance from the lower edge of the hood to the surface of the plate should be about sixty centimeters. The extraction unit works above the stove, where the temperature reaches high values. Due to its large dimensions and improper installation, greasy stains can accumulate on the hood, then it will become dirty by itself. You should be aware that dirt and stains are highly flammable and, therefore, if the hood is incorrectly installed and dirty, a fire can occur.

Ventilation, like any electrical appliance, needs power. When installing, it is necessary to take into account whether the outlet is blocked or not, as well as the distance to it. At the factory, during the production of exhaust devices, they are equipped with a short electrical cord. The most rational option is that the socket should be ten to thirty centimeters higher than the unit and displaced twenty centimeters relative to the axis of symmetry of the device. This is important due to the fact that the air exhaust pipe will go directly along the axis of symmetry.

The air duct of the device has its own design; for the most efficient air intake, it must have a minimum number of right angles, and also must not be pinched anywhere, have distortions. It is necessary to clean the air duct, as it tends to clog. With a blockage, the flow area decreases, so the air does not enter in full. This reduces the efficiency and performance of the device.

Installation of ventilation is a responsible occupation, the way the entire system will work, its efficiency and productivity depends on the correct installation. What should be considered during installation? The first step is to decide what kind of ventilation will be: circulating, flowing or mixed. After that, you need to determine the type of ventilation: direct (normal), inclined or built-in. Each of them has its own method of installation and its own tricks, and each of them also has its pros and cons.

Direct hoods

Conventional hoods are often trapezoidal or rectangular in shape. Installed over a gas or electric stove. As a rule, the unit is mounted on a wall, since it is large, so installing it in a cabinet is not an easy task. You need to pay attention to the availability of the outlet. The lower edge of the ventilation should be at least sixty-five centimeters higher than the slab and below ninety centimeters, so that the efficiency of the hood is not lost.

The ventilation hole also deserves attention; not in all houses, designers install holes in the way that is convenient for residents. There is a way out of the situation, this is the use of a flexible corrugated pipe or a rigid plastic pipe for air ducts. It is recommended to stretch the corrugation to reduce the noise level. The hood must be firmly attached to the wall, you should first prepare the wall by drilling holes in it with a puncher and inserting dowels. After firm fixing of the unit, the further installation of the air duct takes place.

Inclined hoods

The main thing in installing inclined ventilation is to check if it interferes with the opening of the wall cabinets. For small rooms, a fifty centimeter hood will suffice. If the room is often dirty or large in size, it is recommended to install air intakes larger than eighty centimeters. If the hood model has an air exhaust function, then you need to additionally install a ventilation pipe and seal the seams that appear.

If the unit operates autonomously without venting, only access to the mains is needed. The distance between such a hood and the hob should be more than sixty centimeters if the stove is gas, and fifty centimeters if it is an electric stove.

How to measure and install?

Vibrations of the pipe are possible during operation. To avoid deformation, it is recommended to leave some space between the exhaust pipe and the ceiling. You can install it either independently or resort to calling the wizard. The ventilation system is installed in several stages. A measuring tape measures the required height from the plate to the expected start of the hood. With the help of a special level, a line is drawn parallel to the horizon. It is the limiter of the height at which the lower part of the air intake housing will be located.

After drawing a line, you need to find its center and draw a perpendicular straight line from it using a level - this line defines the place where the duct will be located. Next, we measure the device and roughly compare its dimensions with the lines already marked. If the upper edge of the unit rests against the ceiling, then the air duct will need to be shortened so that the air intake housing does not fall below the mark where it cannot function normally.

Next, we measure the distance from the bottom edge of the device to its upper mounts on the case.Let's draw perpendicular lines to the lower horizontal, and connect the ends of these lines to each other to get two parallel lines (upper and lower). On the upper horizontal, we measure the distance from the center, noting the location of the unit mounts. Using a drill or punch, you need to drill holes in the wall, insert dowels into them, into which screws will be screwed in the future.

It is recommended to install the device on the wall from its top, after installing the top. Align the device horizontally and finally fix it to the wall. At the very end of the work, a corrugated pipe or a plastic channel is attached to the air intake. It is recommended to hang the air intake after thorough preparation of the kitchen, after all the measurement procedures and after reading the relevant documentation. At each plant, an installation and operation manual is attached to the exhaust unit, which indicates the parameters for the installation of a specific type of device.

On average, the lower edge of the hood during installation should be 65-90 centimeters higher than the plate. If set below the required height, there is a possibility of damage to individual structural elements and the ignition of fatty deposits on the air intake. Correct installation guarantees the safety of life, just like the correct connection of the device to the electrical network.

Since fat droplets enter the device during operation, which settle in the air intake filters and outside, and moisture accumulates inside, there is a possibility of getting an electric shock if the unit was connected incorrectly during installation.

Also, due to the accumulation of impurities in the pipe section, the area of the passing air decreases and the productivity of work is lost. When installing a ventilation duct, be sure to make sure that it does not block the only opening in the room. Otherwise, the windows may fog up, the remains of an unpleasant odor in the room. If you have one vent, then you should break through an additional outlet from the ventilation shaft and install an air bypass valve there. The valve will close the air flow when the air intake is turned on. For houses outside the city, the best way is to punch a second hole in the wall for the duct.

You need to punch so that the channel does not touch the already existing hole. The pipe from the unit is led out into the drilled hole. An air bypass check valve should be installed at the end of the hole so that air from outside the house does not enter through the additional hole to the inside. In a standard two-room apartment of an apartment building, it is not always possible to make a second hole. In this case, there are two ways to solve it: expanding the channel or using a special adapter that has two holes. Installation of the hood can be done by hand if you have sufficient qualifications and knowledge, but experienced people advise calling specially trained workers to install the hood.

In the next video, you will find the installation of a hood in the kitchen.

Good article.

The comment was sent successfully.