Types of grilles for air ducts and the nuances of their installation

The ventilation grill (ventilation grill) is an element of the air duct (ventilation duct), without which no production, office, kitchen and restaurant room can do. It gives the ventilation duct completeness, harmonious appearance.

Appointment

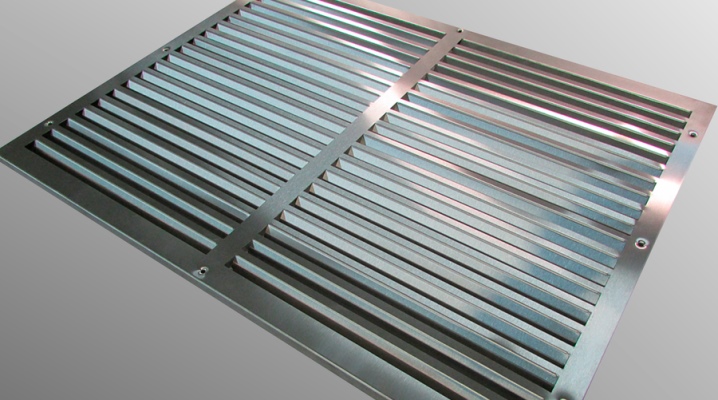

Ventilation grilles for air ducts are an element that ensures not only a pleasant appearance of the entire ventilation duct as a whole, but also protection, for example, from wasps, flies and mosquitoes flying into the room. The design of the grille, despite the apparent noticeable width of the slots (such as "blinds"), also provides for the installation of a metal mesh under the front panel (indoors or outdoors). The mesh is hidden behind the "louvered" slots of the ventilation duct and is not striking for the guests and owners of the facility.

In addition to their main purpose, the grilles can control the air flow. - on sale there are movable versions of them, providing for the rotation of numerous (up to several dozen) parallel curtains, as is observed, for example, in the air ducts of a window air conditioner, which discharges cooled air into the room in which it is installed.

Views

The main types of ventilation grilles are adjustable (with pivoting curtains) and without them. In the first case, the user gets the opportunity to direct them in an optimal way, so that the ventilation is improved, or, conversely, the draft is reduced. The swivel shutters (lamellas) are operated either manually by means of a separate swivel pin or by means of a small stepper motor.

Non-adjustable ones include, for example, grilles for a round duct, and not with a square or rectangular cross-section. This is due to the difficulty of organizing a consistent rotation of the curtains in a non-rectangular duct, since a guide installed in the middle can spoil the appearance, while it should be hidden. However, in recent years, products with a circular cross-section of the air duct, which are designed specifically for the controlled supply or extraction of air, have been actively distributed.

This is achieved due to a special engineering and design solution, thanks to which the guide can be combined with one vertical lamella, similar to the horizontal ones. This guide is hidden behind this bar.

However, the round and oval design also hides a slightly more complex installation. Round grilles are made in the form of cylindrical metal structures - such are, for example, ventilation grilles for the interior of a passenger car, used with equal success by truckers in the cab of a truck, bus drivers (and other public transport). The opening for the air duct was already initially adapted by the car manufacturer for products of the corresponding design - nothing new needs to be purchased. Thanks to their downward-tilted curtains, the louvres are designed to prevent water from getting inside, even during an oblique rainstorm, which is observed with a strong crosswind.

In addition to gratings with parallel horizontal strips, perforated sheets made of stainless steel or aluminum are used, installed in technical compartments and transitions. They are often used as a substitute for a simple mesh. In residential buildings, a mandatory mesh or finely perforated sheet is installed, thanks to which insects will not penetrate inside.

Ceiling ventilation is complemented by a suspended or stretch ceiling.

To create a ventilation duct in such a ceiling, mainly ceiling air ducts are used, passing under the ceiling in a limited (no more than 30 cm) sub-ceiling space.

Materials (edit)

Plastic ventilation grilles are the easiest option. Their disadvantage is sensitivity to heat and frost: some types of plastic, especially cheap ones, are prone to degradation from heat and ultraviolet radiation. Such gratings can crack in no more than 10 years. However, HDPE is resistant to sun cracking during these years, so it is used as a relatively unbreakable material.

Stainless steel grates are the best option. However, steel has about three times more weight than aluminum, so the latter actively displaces it. Aluminum gratings are three times thicker, which allows you to achieve the same results in terms of durability as in the case of stainless steel: aluminum alloys are insensitive to intense corrosion in a simple aqueous environment (rain, tap water when washing the grate).

Rarer varieties are made from other non-ferrous metals (for example, brass, bronze, copper), as well as wood. Grilles made of simple rusting steels - type St3Sp or a similar composition, are additionally made galvanized, chrome-plated or nickel-plated. The disadvantage of aluminum gratings is unsatisfactory rigidity.

Installation

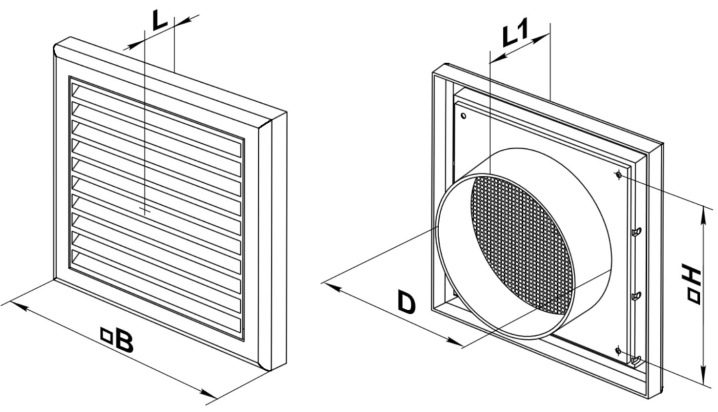

The inset of the grille into the ventilation duct has a number of features. The outer grille is represented by the following elements: flanged frame, louvered decking, protective mesh fence. On the edging part (frame structure) there are fixing holes for which, with the help of hardware, all components are fixed at the entrance to the exhaust shaft.

The ventilation duct can be carried out independently.

For this, a finished shaft (brick pipe) is either built as part of a building or structure, or galvanized or stainless steel hoses are laid. The last step is to install the grille itself.

Before installation, make sure that the grille is suitable in cross-sectional dimensions for a specific ventilation duct, then prepare hardware and tools. First, a border frame is installed on the wall, then a protective mesh is inserted inside, then the blinds are attached.

There are also models of products that are not attached to holes drilled in the wall or in the sides of the metal hose, but are inserted into the ventilation duct using spacer locks. To eliminate the hum from vibration (if the fan motor is powerful enough and will begin to resonate with the grille and air duct), a rubber gasket is installed under the grill itself.

When you install the grill frame, you can place a small piece of thin rubber underneath it. It will serve as a kind of gasket and will exclude the possibility of noise, hum and excessive vibration of the structure, as well as the mount itself.

After some time (for example, a year of operation), the grille (mesh and blinds) are washed out of dust, debris and soot. This will keep the structure clean.

The comment was sent successfully.