Types of fittings for air ducts and their selection

The air duct is steel pipe to form the ventilation system... From individual metal elements, by means of fasteners and other products, a path is laid out along which air subsequently passes. Modern models of air ducts include different fittings from which the system is assembled.

Peculiarities

The main purpose of the air ducts is to organize the ventilation system of the premises. The branches of the structure are gradually laid to each room in the building, and then the general complex is diverted to the ventilation riser. Due to the correct installation of the air ducts, it is possible to adjust various factors:

-

pressure;

-

temperature.

The result is a comfortable indoor climate. Air ducts, in turn, are assembled from separate parts and elements that have different shapes and designs. Among the features of the fittings are:

-

long service life;

-

high strength;

-

reliability;

-

resistance to corrosion and wear;

-

the ability to use in high temperature conditions.

Shaped parts of the air duct include various fittings and pipe sections for organizing ventilation.

Varieties

An air duct is a whole complex of fittings, which include different components.

-

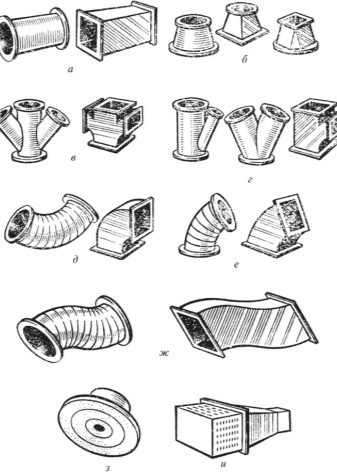

Straight line segments... They represent the main part of the pipe channel, look in the form of a straight pipe.

-

Nipple... An element used to securely connect pipes of the same diameter.

-

Plug... With its help, it is possible to block the opening of the pipe, to protect it from the penetration of harmful substances, dirt, dust or water.

-

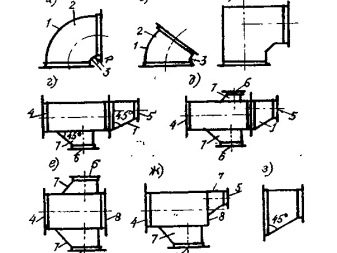

Bends... This is the angle or turn through which it is possible to turn the ventilation system in the required direction.

-

Dampers and valves. Necessary if closed branches are required, flow regulation is needed.

-

Ducks... They are used if there is a shift in the level of the pipe laying. In this case, you can do without bends.

-

Crosspieces... Elements of the duct routing in the required direction and the formation of branches.

-

Umbrellas... They act as protection of the pipeline, preventing the penetration of sediments.

Manufacturers produce fittings of different sections. Here are the main options.

-

Round... They are characterized by increased tightness, reducing the risk of loss of air masses. Additional advantages include ease of installation, low weight and no pressure drop in a system organized from round elements.

- Rectangular... Air ducts of this type are made of high strength materials. Shaped parts do not require special efforts during installation; among the advantages are high throughput and density.

Air ducts are formed from both round and rectangular fittings, often combining elements.

Materials (edit)

Fittings, nipples, umbrellas and other elements of the ventilation system are made of different materials.

-

Plastic or PVC... It is considered a fairly budget option, from which both round and rectangular elements are made. Other advantages of the material include the absence of corrosion, safety of use and ease of installation. The disadvantage is insecurity from fire.

- Steel... In this category, there are two types of air ducts: galvanized or stainless steel. The first are distinguished by their universal use, allowing the use of structures in almost any room. The latter have increased corrosion resistance and a long service life.In addition, stainless steel air ducts are easy to install and are not exposed to moisture.

A separate category is corrugated pipes, the advantages of which are:

-

ease;

-

no need to ground the elements;

-

increased tightness;

-

resistance to high temperatures;

-

good indicators of elasticity.

Corrugated metal pipes are considered quite popular on the market and have not lost their popularity for several years.

Selection Tips

The selection of fittings for a duct device is a complex process that should be approached carefully. There are several factors to consider when choosing items.

-

Dimensions (edit)... Fittings can be of different sizes. Round elements have diameters from 100 to 800 mm, and rectangular ones in their dimensions reach dimensions of 600x600 mm or 300x500 mm when it comes to irregularly shaped parts.

-

Laying method... This determines the loads that the system will experience during operation, as well as the thickness and section of the fittings. Therefore, it is necessary to take into account when purchasing duct elements exactly how they will be laid.

-

Price... You should not give preference to expensive elements, since they do not always demonstrate reliable performance. It is better to carefully study the market and the characteristics of each component. With the right approach, you can put together a solid and at the same time budgetary system.

-

Manufacturer... It is recommended to choose fittings from reputable companies. You can preliminarily study the reviews, familiarize yourself with the properties of the elements.

-

Material... When choosing fittings, you should focus on your own preferences and financial capabilities. You should think about the conditions in which the ventilation system will be used. For example, plastic works well in household systems, but is not capable of handling heavy loads. Steel is suitable for ducting in heavy industries, and galvanized metal will be an excellent option for ventilation of offices or laboratories.

The choice of fittings will be simple and quick if you decide in advance on the purpose of the ventilation system, the material and dimensions of its elements.

The comment was sent successfully.