All about plastic air ducts

Both builders and building owners need to know everything about plastic ventilation and exhaust ducts. It is useful to study their types and sizes, rectangular PVC air ducts and round analogs, other models from different materials and their installation.

Advantages and disadvantages

The advantage of plastic ducts is that the pipes are installed very easily and quickly. Even non-specialists do not have any problems. Such constructions are inexpensive. They are lightweight and do not place a heavy load on the load-bearing elements of buildings. From the point of view of sound insulation and decorative properties, polymer air pipelines also show their best side.

A long service life of PVC (subject to normal conditions and minimal care) is guaranteed. The widespread perception of any harm to health is unjustified - again, under normal conditions and when using quality grades of material. Fears that the polymer will degrade under the influence of sunlight are unfounded. Melting at ordinary household temperatures (up to 80-90 degrees) is completely excluded. It is enough to comply with the restrictions established in the technical passport so that you never have problems with this.

However, even the best plastic air ducts do have weak points. And this must be remembered, despite their profitability and practicality. Such communications are not too resistant to fire. Because of this problem, the use of polymer air ducts is unacceptable wherever there are high-temperature technological processes or heating equipment of any purpose.

At industrial, energy facilities, warehouses and other similar places, metal structures are preferable.

Views

According to the degree of hardness

Flexible corrugated air ducts are manufactured both in Russia and abroad. They are suitable for organizing ventilation systems for a wide variety of buildings and structures. It should be noted that such products can belong not only to the soft, but also to the semi-rigid class. When choosing a specific product, you should very carefully evaluate the level of strength. If possible, it is better to choose a design after consulting with specialists.

Reinforced air ducts are also available. They are usually made not of PVC, but only with PVC impregnation. Other plastics are used as the basis. An important component is a reinforcing steel wire frame. A polyolefin film can be applied around it.

By the way the elements are connected to each other

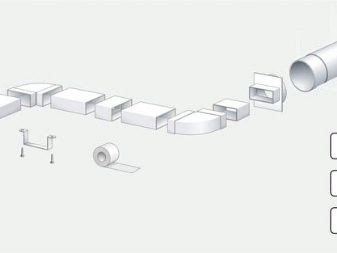

Docking plastic ducts can be done as simply as possible. For this purpose, a large number of connecting units and adapters have been developed in different combinations and with different dimensions. Shaped sections of the structure are tightly strung on the highway. Therefore, no reinforced sealing is required. Polymer clamps and aluminum tape help to connect a non-rigid duct based on a corrugation.

Flanges or other connecting elements can be used to assemble parts. Flanges are created on the basis of angle bars. They are placed at the edges of the sections to be connected. You will have to drill channels to tighten the mounting bolts. The gaps of the flanges are filled with gaskets.

Bolts and nuts must be tightened very carefully. All nuts are brought out to one side. If pipes are installed vertically, the nuts should be on the side of the bottom flange. It should be borne in mind that flange mounting is laborious and requires a lot of metal. Relatively lightweight flange products are formed from a strip profile with a zinc layer.

In some cases, connecting buses are used. They look like collapsible flanges. Such structures are made of galvanized profiles in the manner of the letter "G". Such a product is inexpensive. Its installation is not particularly labor-intensive.

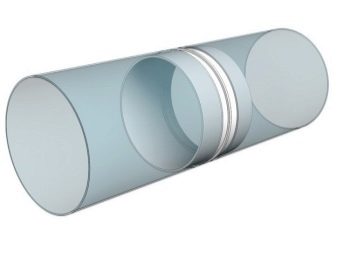

Plastic air ducts are often created in a flangeless type. In this case, bandage and nipple structures are used. The nipple should be at least as thick as the pipe. It is inserted into the pipes to be connected or strung on top of them. The coupling is a synonym for that very nipple.

In any case, the grip must be of equal length in width.

Materials (edit)

Various types of plastic can be used for the manufacture of air ducts. The most widespread is their production from PVC. Such material is designed for use in the range from –30 to +70 degrees. Therefore, installation is allowed even in unheated rooms. In other cases, other plastic structures are more attractive.

So, in some areas of production and laboratories, PVDF is used, it is also fluoroplastic. It is acid resistant material. The minimum temperature for the operation of fluoroplastic pipes is –40 degrees. The maximum allowable heating up to +140 degrees.

Sometimes a polypropylene air duct is also used. Its advantage is increased resistance to aggressive substances. High-quality polypropylene survives contact with alkalis and acids well. Even corrosive organic reagents have no effect on it.

Sometimes low pressure polyethylene (abbreviated as HDPE) is also used. Such a material is especially flexible and resists mechanical damage well, but suffers greatly from low temperatures.

It is imperative to take into account the characteristics of specific plastics. So, in kitchens, polypropylene hoods are quite sufficient. For residential and utility rooms, polyethylene boxes are preferred. And in places with a particularly high air temperature, PVC and PVDF are relevant. In special cases, vinyl plastic and metal-plastic can be used.

Fluoroplastic can be used in the industrial sector, in factories and factories where the air contains a large amount of corrosive and corrosive chemicals. This is primarily about oil refining, the production of chemical and pharmaceutical products. Fluoroplastic also almost does not slip. Therefore, the passage of air through such a line has a very high efficiency. The declared ability to withstand heating up to +250 degrees and cooling down to -100 degrees.

Polypropylene is prized for its relatively low cost. It is able to withstand heating up to +100 degrees for a short time. But if the temperature rises another 30 degrees, melting will begin. Therefore, polypropylene air ducts cannot be used in rooms where there is an open fire, including gas stoves and any burners. The metal-plastic air duct has a complex structure.

In it, the inner and outer layers are distinguished. They are made from galvanized steel or thin sheet metal. The space between the layers is saturated with foamed polymers. The role of the outer metal layer is mechanical protection.

And also, to some extent, it protects plastic from ignition with a weak effect of open fire.

Dimensions and section types

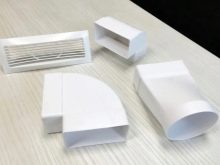

The rectangular duct can have a cross section of 110x55 mm. But the same category includes complexes 120x60, and communications with a size of 204x60. The rectangular shape is ideal for living rooms, kitchens and industrial premises. This configuration allows for ease of installation. The rectangular duct is easy to stretch both under a false ceiling and in hard-to-reach areas of premises.

Flat piping can be custom configurations in which the length is 4 times the height. It is a subspecies of rectangular design. In this case, the assembly is usually done manually. Most often, such models are created for hoods. Significant noise levels are a problem, however.

A modern round duct is usually made with a diameter of 100 mm (the same as D100). And also there are models with a section of 125 mm or 150 mm. The effectiveness of such channels is very high. The resistance to air flow inside the circular pipe is minimal. The volume of extraneous sounds will be low.

The square air duct can be sized:

- 150x150;

- 200x200;

- 100x100 mm.

For round models, the cross section is often 200 mm. For rectangular ones - 200x60. Sometimes larger - 250 mm, or smaller - 160 mm - complexes are used. And also there are plastic air ducts 80 mm in size, 120 mm in size. In some cases, the size is set more precisely - 55x110x1000 mm.

Selection Tips

In addition to determining the desired material, it is necessary to pay attention to the technical characteristics. The volume of air that passes through the ventilation duct per hour is critically important. This cost is determined by the volume of the room and the normal rate of air exchange. The speed of the air jet should be such that there is a balance between noise and performance level.

Typical dimensions are standardized and reflected in the reference books. If the area of the room does not exceed 50 sq. m, it is necessary to use round channels with a cross section of 100 mm. An alternative to them are rectangular structures with a size of 60x120 mm. With a size of 51-99 sq. m will require models of 150 mm and 60x240 mm. Sometimes complicated circuits are required.

In this case, you will need the advice of experienced professionals.

The rectangular configuration is prized for its precision and tight fit to functional surfaces. It is advisable to use it when arranging an air duct under a false ceiling and in other places where fastening is difficult. Round ducts are more difficult to install. True, they can reduce the noise during ventilation. A round duct is especially good if you need to equip a short section of the room, or take into account specific design requirements.

Flexibility for a residential air duct is not too important. But it is more correct to create structures of a complex structure just from corrugated parts. In terms of durability, polyurethane pipe with steel spiral reinforcement stands out in the best way. These are mainly round models. The smaller the bandwidth, the more noise (with identical performance) it will create.

Fittings are selected according to the size of the channels. The length of household air ducts is from 40 to 250 cm. For longer lengths, a special fitting joins a pair of sections. Many manufacturers offer custom air ducts. Of course, all parameters must correspond to the chosen installation scheme.

Application

Most often, air ducts are used for general ventilation. The same communications can be used in both active and passive systems. Ventilation ducts can also be designed for:

- garage;

- a factory workshop with gentle operating conditions;

- office building;

- shopping complex;

- educational institution;

- exhibition and entertainment institutions;

- hoods in the kitchen;

- hoods in the laboratory;

- air conditioner, industrial fan and other equipment.

Installation features

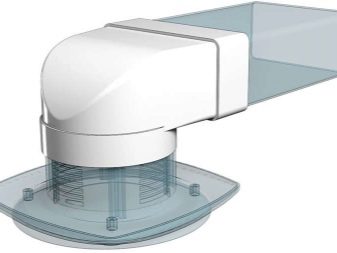

It makes sense to disassemble this using the example of installing a kitchen hood. From it to the output, you will have to equip a box. Such a box is hermetically connected to the ventilation hole. If necessary, the hole is further expanded. The supply scheme is formed independently.

The box is mounted for the first time in a "dry" way (for fitting). The second time it is done with the addition of sealant. In some cases, an adapter will have to be installed between the duct and the ventilation grill.The sealing compound should be based on acrylic or silicone.

Schemes should be drawn up taking into account the profile SNiP.

Air inflow and outflow must be ensured in every room of the house. For natural ventilation, a flat plastic pipe is better suited than a corrugated analogue. On the other hand, supply and exhaust complexes are created mainly by corrugated structures. The shorter the length of the ventilation line, the more efficient it works. Outside, the pipes are often built up, and even if it does not look too elegant, the practicality of such a solution fully justifies all the efforts to mask it.

The fans are set so that there is a slight flaw on the inflow, and activity on the outflow is slightly higher than it should be. This makes it possible to activate air exchange between the manned rooms. Normally, it should allow you to renew all the air in 60 minutes. Separate exhaust ducts are provided for kitchens and fireplaces. At the same time, stoves, fireplaces and stoves should have specific hoods, clearly separated from the general ventilation ducts of the kitchen and boiler rooms.

The comment was sent successfully.