Stainless steel air ducts

Stainless steel air ducts - one of the most common types of this technique. Consumers will be very interested in understanding specific types of stainless steel air ducts and their installation. Corrugated, welded and other models for ventilation deserve attention.

Peculiarities

The specificity of each type of air duct is beyond doubt. And stainless steel air ducts are no exception. Their manufacture, as in other cases, ensures the prompt removal of exhaust air and the pumping of fresh air masses instead. Strong steel with special components does not rust. This metal is very dense and resistant to high temperatures.

Stainless steel is also immune to most corrosive substances found in everyday life, in office buildings, and even in industrial facilities. Technologists have learned how to create steel air ducts with any section and with a wide range of characteristics. Such structures can provide removal of air saturated with corrosive and toxic substances. In comparison with galvanized steel, stainless steel is characterized by increased heat resistance.

The heat capacity is large enough to remove the heated air from the stove, fireplace.

In addition, they note:

- excellent wear resistance;

- resistance to moisture ingress;

- biological stability of stainless alloy;

- ease of operation and cleaning;

- ease of installation;

- attractive appearance.

The thickness of steel sheets released for the manufacture of air ducts ranges from 0.6 to 1 cm. Most often these are low carbon steel products. Corrosion resistance is achieved by introducing a noticeable amount of chromium. Special additions of alloying elements provide increased strength. Categories of pipes for air ducts are clearly divided by chemical composition - and each type can work with its own range of tasks.

Views

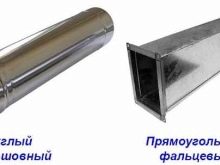

Stainless steel air ducts differ primarily in format. The most common are rectangular and square patterns. They are versatile and practical. Such communications do an excellent job of pumping fresh air or removing exhaust air. Round models are rarely used - they are not so in demand, because such routes are more difficult to arrange and secure.

In some cases, air ducts have non-standard geometry. Each such object is custom-made. Often these air ducts are ordered when existing systems are being modernized or replaced. It is also important to take into account the steel grade, which is selected taking into account the purpose of use. Alloys are widely used:

- 12X7;

- 08X18H10T;

- 08Х17Н14М2.

A straight-seam duct pipe is formed on a sheet bending machine. The opposite edges of the blank to be created have an open, even shape. That is why, when connected, they form a straight seam. The connection is ensured by induction welding or TIG welding. The final profile is created after passing through the sizing rollers. The corrugated air duct is made on the basis of multilayer foil. Its total thickness is not less than 0.12 and not more than 1 mm. The contact of the foil sections is ensured by the locking technique. The seam is secured with a special stainless spring. Spiral ducts can be made in different ways.

So, their locking subspecies involves twisting a stainless tape into a spiral.The locking connection at the ends of the tape is formed immediately. Already at the exit from the processing machine, the product is completely ready for use.

There are also welded spiral patterns; the strip blank is twisted into a spiral and stretched in different directions. Docking between the turns is done by conventional welding.

The spiral duct is considered to be more efficient than the longitudinal seam type. It has increased rigidity. This property is retained even over long sections. The advantage is connected precisely with the spiral passage of the seam. Taking into account the operational parameters, the surface can:

- polished;

- have a matte look;

- be sanded.

Round and rectangular air ducts can be made of steel of various grades at the choice of customers and designers. In addition to chromium, a number of other improving additives are introduced into it - titanium and carbon, sulfur and phosphorus. Often steel grades are chosen not according to GOST, but according to the AISI system, which in practice has shown its advantages in terms of describing the characteristics of the metal. A good choice is considered:

- ferrite alloy AISI 430 (cheap and corrosion-resistant metal);

- martensitic steel AISI 304 (heat-resistant and hard metal that resists corrosion well);

- austenitic AISI 321, 316 is a particularly corrosion-resistant product, characterized by its plasticity and good pressure treatment.

Where are they used?

For ventilation, rectangular ducts are often used. They perfectly remove hot air from the boiler room or heating point. Such complexes are used in smoke removal systems to remove air containing corrosive and caustic substances. Round air ducts are often used to extract air in extreme conditions, to transport it there. We are talking about:

- saturation with toxic fumes;

- operation at high temperatures;

- the content of foreign gases.

Stainless steel air ducts are used in:

- medical institutions;

- Food Industry;

- other industries;

- various objects in the zone of humid marine climate;

- pools, water parks;

- cafes, restaurants, other catering establishments;

- administrative buildings.

Mounting

Rectangular stainless steel structures are strictly rigid. For round products, rigid and semi-rigid shapes are typical. The fastening to the wall itself can be done:

- with the help of sockets;

- due to flanges;

- by means of tires;

- by means of electric welding.

Flange mounting involves the use of bolts and rivets. The socketing technique involves joining the ends of the pipes. They are tightly fixed from the outside. Special tires guarantee the tightness of the pipe thanks to a special clamping device, supplemented with a lock. Gaskets made of rubber or foam help to increase the density of the bond. The attachment of duct pipes by welding is quite reliable. This method makes it possible to guarantee the impermeability of each joint. For manipulations, you will need a specialized thermal gun. All cutting and soldering points are marked. The excess metal is cut off with a special knife.

Parts of the duct are fixed on elongated brackets. They are good because they allow you to avoid deformation. The pipes themselves must be secured with clamps. They are tightened with an open-end wrench. A special feature is the pulling of air ducts through ceilings or wall panels.

In this case, use sleeves or other metal adapters. Important: all horizontal ventilation segments must be oriented symmetrically. If the main elements are mounted vertically, then the gap between the brackets should be from 1 to 1.8 m. Arrangement of turns is almost impossible without the use of:

- bends;

- sidebars;

- crosses;

- tees.

To reduce noise, use specially selected plugs... When installing ventilation communications, not only air exchange is taken into account according to calculations. We will also have to pay attention to maintaining optimal purity of the incoming inflow. In the exhaust system, one hood serves to extract and supply air; in the supply and exhaust systems, these functions are clearly separated. The stainless air duct must be grounded to avoid the accumulation of static electricity.

Flexible and partially flexible products are installed under the condition of full stretching. In basement and basement floors, the use of rigid steel ducts is recommended. The same rule applies to areas in direct contact with the ground and when passing through floor and ceiling slabs. All pivot points and aerodynamics of air movement in them are calculated separately.

Any sagging and irregularities are strictly unacceptable (air ducts are not wires, and air pressure will be lost in them with such an installation).

The comment was sent successfully.