All about grape crushers

Winemaking is a beautiful but complex process, starting with the cultivation of grapes and ending with the aging of an excellent drink. One of the intermediate stages in the processing of the crop is crushing the bunches. Initially, it was done by hand, more precisely "with a foot", then the first mechanical device was invented, which has undergone a number of improvements over the centuries.

Features and purpose

The purpose of the crusher is to squeeze out juice from berries, separate seeds, ridges, cake. It is indispensable in farms that cultivate wine grape varieties. A feature of the device is the presence of a gap between the working shafts. This technique allows you to crush the mass without crushing the seeds, since damaged seeds give the wine an unpleasant bitterness, negatively affecting its quality and taste.

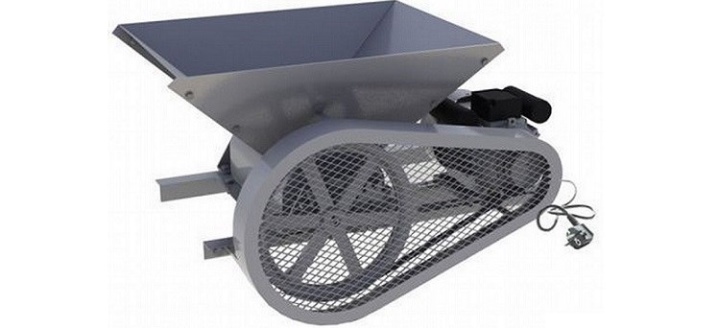

The construction device is so simple that it can be made with your own hands. The grapes are loaded into the receiving hopper, from where they are fed to the movable shafts. The rotation transforms whole berries and bunches into wort, which flows down into a special container. The further process already takes place without the help of a crusher. One of the varieties of crumbs is a juicing press.

The grape pressure design has undeniable advantages and is not devoid of some disadvantages. However, they are so minimal that they do not play a significant role.

Advantages of using a crusher:

-

technological waste is qualitatively reduced;

-

time costs are reduced, the quality of the pulp is increased;

-

after the crusher, there are no undesirable components in the grape mass;

-

a mechanical or manual unit works even in the absence of electricity;

-

crushers for grapes made of stainless steel are of high quality, do not corrode and absorb foreign odors, the simplicity of the device allows you to make the necessary changes, improve the apparatus for the needs of the owner.

The downside is the selectivity of some models - mills with a comb separator cannot work with nutmeg varieties. The price of production models may seem too high, but the performance and quality are worth the investment.

Views

Grape growers use several varieties of grape crumbs, with which the harvest is processed. The devices differ in several ways.

By the presence of a comb separator

A crusher with a comb separator is used for processing white muscat grapes. It's all about the mandatory requirements for muscat wines - they should not contain bitterness, which is given by the combs, which have a high content of tannins. It is for obtaining such a wort that models with a comb separator are chosen. In the case of working with red wine varieties, the presence of a crest in the wort is mandatory - it is it that gives red wine an exquisite astringency and depth of taste. Such crushers assume a roller or impact-centrifugal type of mechanism operation.

By type of management

Winemakers use 2 types of grinders.

-

Hand crusher. This is a roller type mechanism, the design of which includes: a feed hopper, a shaft, screw blades, horizontal cylinders and a wort receiving container. Horizontal cylinders are located inside the unit parallel to each other, make a counter rotating motion and crush the berry. A specially designed gap stops the ridges and guides them out.

- Electrical devices... They are based on a shock-centrifugal principle, they squeeze fruits using an electric rotor and have a high productivity: they give a large yield of wine base, dyes and phenols. Juice extraction occurs with the simultaneous separation of the ridges and their removal from the total mass. As a result, the winemaker has a clean pulp at the exit.

The preference for this or that model is given according to the volume of the product produced.

It is not advisable to use manual devices in vineyards with an area measured in tens and hundreds of hectares. For growing grapes in summer cottages and getting wine, on the contrary, the purchase of electrical equipment is unprofitable.

Popular models

There are many manufacturers offering grape grinders on the market. Below are the TOP 5 most popular models.

DMA

Italian auger shredder with comb separating. Manual control seriously reduces the cost of the product and makes its operation more convenient - the unit can always be moved to a better place. The crushing machine is easy to care for, wash and clean. Crusher width - 500 mm, weight - 39 kilograms, hopper length - 0.9 m.

LOZA-M

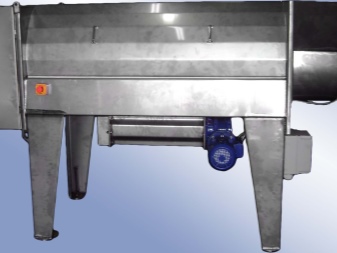

Another shredder of the Italian brand with a comb separator and two types of control (electric and manual). The polypropylene hopper is designed for 40 liters of loading, the auger shaft and millstones of the crusher are mounted on bearings made of high quality stainless steel, which guarantees a long service life.

The unit separates the ridges with high quality and is designed for processing large volumes.

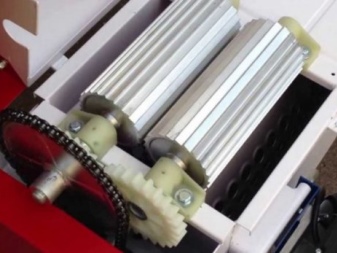

Mechanical crusher Polsinelli

Mechanical design without comb separator, all external parts are coated with safe powder pigment. Horizontal shafts are made of duralumin, which increases the resistance of the material to corrosion processes and increases the service life.

Electric crusher "Clever" EI-1

The dimensions of the device are 4.4x2.5x0.7 m, weight - 11.5 kg. The unit is designed for processing fruits of various varieties - in addition to grapes, the crushing machine is capable of crushing strawberries, apples, peaches and other fruits. Thanks to this crushing machine, winemakers can produce not only grape, but other wines as well.

The productivity of "Clever Girl" reaches 1 ton per hour.

Manual chopper with MOLINARA comb separator

The manual shredder with stainless steel hopper can be used to process Muscat and red wine grapes. The unit can be used both in small households for home winemaking and in large wineries.

The listed models of shredders are the most popular of this segment, which, in fact, offers a wide range of products.

Selection Tips

When choosing a grinder for grapes, first of all, they are guided by the volume of processed products. The requirements for a crusher are strikingly different in large farms and in small summer cottages. The first measure the yield in tons, the second - in tens of kilograms. For large wineries, you will need a model with an electric drive; for a summer resident, the manual option is optimal.

Depending on what wines are produced, a crusher with or without a comb separator is chosen. The size of the keg is also chosen based on the amount of processed berries. The tank can be from 10 liters or more, and for a small garden and a dozen seedlings, a 5-liter volume is quite enough. The type of press depends on how exactly it is planned to install the structure: the screw needs a stationary fastening, and the hydraulic one can simply be placed on top.

How to do it yourself?

The owner of the garden plot, growing vines in small quantities and receiving a harvest of no more than half a ton, can make a grape crusher on his own. This will not only save money, but also allow you to have a device that exactly matches your needs.

Step-by-step manufacturing instructions

For the manufacture of a wooden crusher, you will need an accurate drawing of the future unit, according to which in the future they adhere to the dimensions and perform all the stages of manufacture and assembly.

-

From wooden beams 50x50 cm, a frame is knocked down, whose value is equal to the capacity for pulp.

-

The prepared rollers are fixed in the middle of the frame, leaving a gap of 2-3 mm between them.

-

Next, a pyramid-shaped bunker is made. Use any material that is safe for health. Preference is given to an oak board, but if it is not there, then stainless steel, plastic, etc. are used.

-

Then a container for receiving the cake is prepared and installed, and its size in the upper part must match the parameters of the frame.

-

A frame with rollers and a hopper are mounted on top of the cake receiver.

-

The axis of one of the shafts should continue with a handle that will drive the device.

All wooden parts are varnished. A homemade design can always be improved by adding an electric motor, thereby significantly increasing its performance.

For the manufacture of a comb separator, a fine mesh (10–12 mm), one more horizontal shaft with stainless steel blades will be required. The blades are welded or fastened with self-tapping screws to the shaft in a spiral. Craftsmen make a shaft from a birch cuttings. The mesh prevents the ridges from entering the pulp and directs them to another compartment.

How to make a crusher yourself, see below.

The comment was sent successfully.