Features of vibration table motors

Vibrating tables are equipment demanded in industry and home life, for the organization of the work of which a vibration motor is used. There are several types of motors with which work tables are equipped. It is worth considering in more detail their purpose, principle of operation and mounting features.

general description

Vibrating tables are special equipment designed to increase the strength of concrete and perform a number of other tasks by transferring vibration to the material. The installation is powered by an engine - a high-power unit. Depending on the type of the task at hand, there are:

-

independent devices used for vibration compaction of concrete mortar;

-

units in the role of a drive unit, which are responsible for the transmission of effective vibration to the molding site.

The engine is an irreplaceable part of the table, without which the equipment cannot start working. Through the action of the vibration motor, it is possible to:

-

increase the density of the array and ensure its integrity;

-

improve the fluidity of the solution, which, when concreting, fills evenly all sections of the form;

-

to achieve the required index of frost resistance of concrete, which is susceptible to the formation of microcracks at low temperatures and a porous structure;

-

improve the contact of concrete with reinforcement by removing air bubbles.

And also the engine makes it possible:

-

launching the production of small items by vibration casting;

-

production of various types of tiles and other concrete products;

-

ramming concrete products for both personal and professional purposes;

-

molding of aerated concrete and other blocks.

The action of the vibration motor increases the density of the poured sections, due to which the concrete gains strength faster and the structure becomes reliable. Installation would not be complete without an engine. Therefore, it is worth considering in advance which motor is suitable for installation on a vibrating table.

Varieties

The following types of engines are used as the main source of vibrations.

-

Used motors. Option for do-it-yourself vibrating tables. The power of such devices reaches 1000 watts. The engine will easily transfer the required amount of vibration to a table with a working area of 0.8x1.5 meters. Before starting the motor into operation, it will be necessary to fix two eccentrics on the drive shaft, and provide for the possibility of changing their position. This solution will allow you to adjust the amplitude and strength of the oscillations during the operation of the installation.

- Vibration motor of industrial type. A device for professional use, installed on the surface of a table top. It is an improved vibration motor, already equipped with eccentrics installed on opposite sides of the shaft. The presence of elements allows you to change the degree of vibration exposure of the device.

To use the vibrating table in domestic conditions, the first option is sufficient and, in principle, a motor with a minimum power. For example, many people install motors from washing machines that are out of order on the table.

The power of such motors reaches 220 volts, and this is quite enough for organizing the efficient operation of equipment at home.

For more professional use, the purchase of an industrial motor will be required, which will ensure the stable operation of the installation even when it is necessary to process large volumes.When choosing a motor, in this case, it is better to pay attention to the power, frequency and degree of vibration.

The most reliable drives are distinguished as a separate category, among which are motors of the IV series. The plant in Yaroslavl is engaged in the production of motors, among the advantages of the equipment produced by the manufacturer are:

-

high power;

-

long service life;

-

versatility of use.

The cheapest drive, if desired, can be assembled with your own hands, if you take an existing motor as a base and modify it.

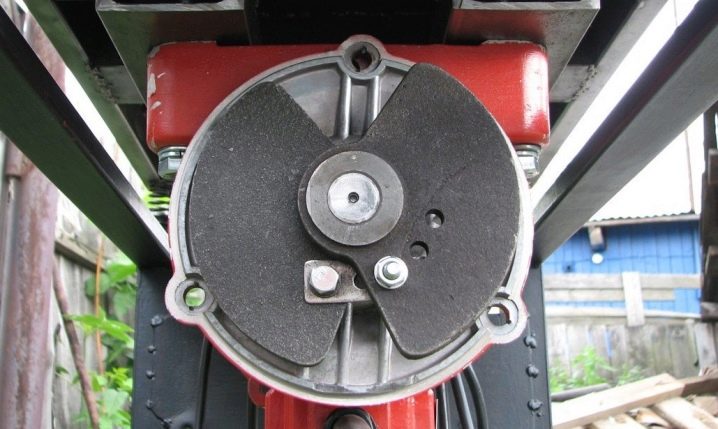

Attachment nuances

Mounting the motor on the vibration table requires careful attention. In order to properly install the engine, it is necessary to take into account a number of nuances. Installation diagram.

-

First, you need to weld a channel with the provided holes on the underside of the vibrating plate.

-

Next, it is necessary to fix the channel horizontally in order to ensure the creation of the desired vertical vibrations of the installation.

-

The last stage involves the installation of the motor, which stands on the channel.

The position of the channel depends on the method of vibration supply. For example, if it is planned to transmit vibrations in the horizontal plane, then the profile is attached vertically, and vice versa. And also when installing the vibration motor, it is worth preventing the possibility of moisture getting on the device.

The comment was sent successfully.