Installing the hob in a worktop

Recently, more and more bulky stoves are being replaced by compact hobs, which are becoming an integral part of the kitchen set. Since any such model must be cut into an existing surface, it is much wiser to study this simple process and do everything yourself.

Peculiarities

The specifics of installing the hob in the worktop largely depends on whether it is electric or gas. Electric, as you might guess, should be located near the power point. Both the cable cross-section and the power of the nearest outlet must be taken into account. You can also not ignore such a procedure as grounding of metal parts. Establishing the gas surface is a little more difficult, as it is important to think about how to dock it to the gas pipe.

In addition, safety requirements categorically prohibit the independent connection of gas hobs. To carry out this operation, you will have to invite an employee of special services, who will pay for everything and will do it. Of course, you can try to install everything yourself, but in this case you will have to expect not only serious sanctions, but also the emergence of a real danger to the life of the inhabitants of the whole house. By the way, the sanctions can go up to the complete shutdown of the gas and the sealing of the valve.

It is certainly allowed to install and connect the electric stove yourself, but strictly following the instructions provided. In the event that a person does not have any skills in working with electrical devices, he is recommended to contact a specialist. If the installation process is carried out incorrectly, then the negative consequences may include not only the disrupted operation of the device, but also its breakdown or even the failure of all the wiring in the apartment.

There are a few more nuances regarding the connection of the hob. For example, the maximum possible gap between the panel and the worktop is 1-2 millimeters. The thickness of the worktop itself must correspond to the minimum figure indicated in the instructions. In addition, the location of the worktop is always aligned with the front edge of the kitchen unit.

Marking

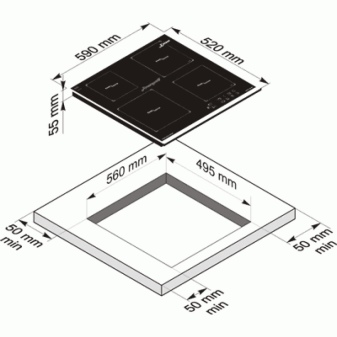

The inset of the hob begins with finding out the dimensions and applying them to the worktop. As a rule, the parameters are indicated in the instructions attached to the technique. If the manufacturer has not taken care of this, then it is realistic and independent to calculate everything. In the first version, the panel is turned over, after which it is encircled on thick cardboard or even immediately on the tabletop. You will need a ruler of sufficient length, a pencil and a marker.

You can try to independently determine the place of attachment. First, the boundaries of the inner space of the cabinet are transferred to the surface with a pencil, on which the panel itself will be located. By the way, when a pencil does not make it possible to apply bright markings, then it is reasonable to first glue masking tape, and then draw. Next, the center of the hole for the body is determined. To do this, it will be enough to draw the diagonals of the rectangle created by the front and rear parts of the tabletop, and the drawn borders of the curbstone.

At the point where the diagonals intersect, two lines are drawn to form a cross.This means that one should run parallel to the edge of the countertop, and the other should be perpendicular to it. On the lines that have arisen, the dimensions of the part of the case that should be built-in are marked. The exact numbers are either determined independently or are extracted from the instructions. Better, by the way, to increase them by a centimeter or two for greater convenience.

If parallel and perpendicular lines are also drawn through the formed marks, then a rectangle is formed. It will not only be exactly in the center, but will also coincide with that part of the hob that should go deeper. If the gap prescribed by the manufacturer remains between the formed lines and other objects, then you can circle the figure with a marker and proceed to the next stage.

Hole cutting

To cut the space for the hob, you need either a milling machine, a fine-toothed electric jigsaw, or a drill. The size of the cut should have already been determined by this time, therefore, further it is necessary to move along the inner side of the drawn rectangle. Holes are created in the corners using a drill with an 8 or 10 mm drill bit. Then straight lines are processed with a file or a grinder. When working, it is important to firmly fix the device case on the tabletop.

V in the case when the tie-in is carried out only when using a drill, the procedure becomes slightly different. The first step remains the same - with an 8-10mm drill, holes are created from the inside of the drawn rectangle. They should be done as often as possible so that the surface fragment then breaks off easily. The rough edges of the resulting grooves are aligned along the line with a rasp or a file designed for small work on metal or wood. The main goal of this stage is to align the edges as much as possible.

Having created a mounting hole, you can already embed the panel itself. The technique should slide into place smoothly and completely close the hole in the countertop. After making sure that everything went smoothly, the burners should be removed for a while, and the cut points should be sanded with sandpaper or a file. The wooden countertop requires additional processing to prevent the penetration of liquid. The cut points have to be treated with silicone, nitro varnish or sealant. The plastic headset does not need such processing.

Mounting

Installation of the hob is not difficult at all. The panel is simply lowered into the cut-out hole and aligned using a measuring device or with your own eyes - everything should look nice and even. If the stove is gas, then the hose with the union nut is supplied even before the panel is installed directly. Having centered the plate, you can proceed to fixing it.

Sealing

The sealing tape is wound even before placing the device itself. Planting it is advised according to certain rules. Usually the seal comes with the hob and is self-adhesive: covered with glue, covered with a protective film. Separate the gum and the paper base gradually as it joins the surface, so as not to confuse it. Planting the sealant is required in a single piece. The thermal tape should follow the perimeter of the hole on the front side of the furniture box. The corners are bypassed to avoid any cutting of the tape. The two ends of the gasket should be joined as a result so that no gaps are left.

Some manufacturers also provide an aluminum seal with the hob. How exactly to install it is written in the attached instructions. However, the use of double-sided adhesive tape by specialists is not recommended - if necessary, it will be very difficult to remove the panel, and it may even break. The application of a sealant is necessary to prevent water from entering the inside of the countertop during use.It can be either an acrylic solution or nitro varnish, which is applied in a thin layer to the inner surface of the hole ends.

Fastening

To integrate the hob correctly, it must be secured from below. Fasteners, which are a combination of self-tapping screws and special brackets, supplied in the kit, allows you to immediately attach the panel to the table top. The device is mounted at four corners. You will have to tighten everything tightly to prevent cracks. The fastening process ends with the return to place of all previously removed parts. After the device has been fixed, it is necessary to cut off all excess sealing gum protruding from above with a sharp tool. In general, it is a very simple task to build in this type of equipment yourself.

Connection

The connection of the energy carrier is determined depending on whether the panel is gas or electric. A gas-powered device cuts into the gas main, and an electric one is connected to an existing network using a socket and a plug. As mentioned above, you should not connect the gas panel yourself, but it is quite possible to study the sequence of steps in order to understand what the master is doing. First, the flexible hose goes through a fitting or squeegee to connect to the gas valve. At this point, a hole for it should already be prepared in the back wall of the furniture.

It is imperative to check for the presence of ricles necessary to connect the stove to the common system. If they are absent, then an operational installation is carried out. The gas inlet nut is attached to the plate. It is important not to forget at this moment to use the O-ring, which in most cases is included in the kit. The connection of the gas hob is followed by a gas leak check. This is quite easy to do - it is enough to cover the joints of the structure with soapy water. If bubbles appear, this means that gas is present, their absence suggests the opposite. Of course, the presence of an unpleasant odor is also a characteristic signal.

With regard to electric stoves, different models offer the user to connect the wire to both a regular outlet and an electrical panel. In any case, it is important to remember that the stove consumes a large amount of energy, which means that the wiring available in the house must meet the requirements of the device in order to avoid any problems.

By the way, one cannot fail to mention the induction hob, which has been gaining popularity lately. It runs on electricity and can be connected either with a cord and socket, or with special terminals that require an external cable to be connected. In this case, in order to activate the plate, you first have to remove the protective cover from the back of the device and pass the external cable through it. Following the scheme indicated in the instructions, the cord is connected to the terminal plate. If there is a jumper between zero and ground, it will have to be removed.

For an overview of the Siemens induction hob, see the following video.

The comment was sent successfully.