Installation and repair of a bathroom faucet with a shower

A bathroom in our time is a complex complex of a wide variety of devices, plumbing connections and assemblies. As for the faucets, there can be two or three of them - it all depends on how many and what is installed in the bathroom. Any technique tends to break sometimes, and mixers are no exception, so you need to know what to do in these cases. Having detailed information and an algorithm of actions, you can easily eliminate minor faults with your own hands.

Types: design features

Every modern bathroom is sure to have a mixer. Replacing the bath with an invigorating shower significantly saves water consumption. Sometimes the mixer breaks down, then repair or purchase of new units is required.

The faucet is one of the main devices in the bathroom, it is also in the bathroom, and in the shower cubicle, and in the sink, if it is installed separately. With the help of this unit, you can regulate both the water pressure and its temperature.

Mixers are of the following types:

- valve;

- single-lever.

The first one includes two valves, which, with the help of rotation, allow you to achieve the desired water flow and temperature. Such a unit is arranged simply, if necessary, it can be easily disassembled and repaired. When working, it is important to follow the recommended sequence of operations, this is the best guarantee that there are no unnecessary parts left after assembly.

Water regulation by means of the second type consists in the fact that the lever is lifted upward and rotated to the side. Inside this structure, there is a large ball, which has special slots and is in contact with the lever.

Water at different temperatures enters through such slots and mixes. The water pressure is regulated by changing the angle of rotation of the lever.

The model with a ceramic cartridge has two plates that are in contact with each other. The plates move relative to each other when the arm changes position. This allows cold and hot water to mix.

The axle-box crane is reliably protected by seals, which can be:

- ceramic;

- rubber.

Valve head assemblies can be changed. The axle crane, in turn, may consist of:

- from tees;

- from the branch pipes.

The tee connects several pipes, the second type is connected using a special wiring.

The lever mixer is very popular, its main advantages are:

- ease of use;

- reliability;

- looks aesthetically pleasing;

- ease of installation.

The device diagram of such structures is simple; unfortunately, it is not possible to repair them; the case is designed in such a way that it cannot be disassembled.

Switch types

Tap-to-shower switches can be of the following types:

- cork;

- push-button devices;

- cartridge type.

- spool valves.

The most common and simple ones are cartridge-type switches. Their main breakdown is the wear of the rubber ring between the housing and the shift lever. The rubber of the gasket is located in an environment in which there is both high humidity and mechanical stress. Destruction of the gasket is only a matter of time. It is not difficult to eliminate the malfunction, for this you need to disassemble the device and replace the gasket.

What needs to be done to repair the crane:

- shut off the water supply;

- disconnect the lever from the mixer;

- unscrew the screw from the switch;

- dismantle the switch;

- install a new ring;

- wind the FUM tape on the thread in several layers;

- put the lever in place, tighten the screw.

A common occurrence in spool switches is that the nut breaks, it fixes the switch in the shower itself. Similar incidents happen when the materials from which the mixer is made are made of cheap silumin material.

It is recommended to buy nuts and hardware made from hard alloys:

- brass;

- bronze.

Such a malfunction is eliminated as follows:

- the mixer is disassembled;

- the hose is unscrewed from the shower;

- the lower nut is unscrewed.

If the nut is out of order due to thread wear, then it should be replaced with an analogue made of a higher quality material. After processing with sandpaper, the device is assembled, lubricated with grease and put in place.

Breakdowns and their causes

Often, breakdowns occur at switching points for other reasons:

- failure of the button;

- the passage of water simultaneously into the faucet and shower hose;

- failure of the mechanism that controls the flow of water;

- abrasion of the gaskets in the push-button switch itself.

The leak can be eliminated by changing the rubber rings. The pushbutton switch breaks due to the failure of the metal spring, which must be replaced.

If there is a decrease in the water pressure in two-valve type taps, then it is quite possible that a clogged aerator is to blame, it should be cleaned. It is also possible for the spools to fail, which are responsible for the flow of water entering the tap and shower.

Such assemblies from bona fide manufacturers are designed for a long service life, so it is recommended to buy plumbing fixtures from reputable trading platforms. Each unit of goods must always be accompanied by genuine quality certificates and warranty obligations.

Trouble-shooting

In order to repair breakdowns, you should use the services of masters with practical experience. In this case, it is good to have certain ideas about how the mixers are arranged, and what types they are.

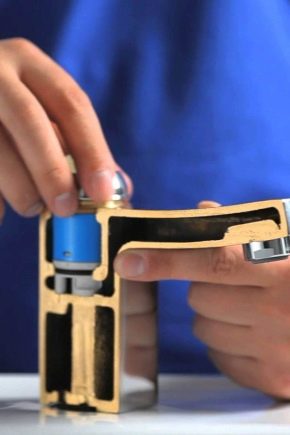

Any mixer consists of several units:

- frame;

- rubber gaskets;

- crane box;

- decorative elements;

- valves;

- spool;

- adapter;

- crank.

The most common malfunctions are in the form of a leak, they are:

- under the gander;

- under the mixer lever;

- under the mixer valve with two valves;

- at the connection points of the hose and shower.

- under the fastening nut, water may leak due to the wear of the gasket.

In this case, the repair can be done by hand; the qualifications of a plumber is not required here.

Often, faults can be easily eliminated by replacing a worn out ring with a new partonite ring. When winding the gander, it is imperative to lay the FUM tape so that the gaps are better sealed. Leakage in a lever mixer occurs when the cartridge itself breaks. Such a malfunction can be eliminated by replacing the cartridge. It can be of different sizes, it depends on the manufacturer. When buying a new cartridge, it is advisable to take with you the broken one, their compliance should be 100%.

Leakage from under the lever is eliminated in this way:

- first, the cap is removed, which is marked with a red-blue marker on the handle;

- the fastening bolt is unscrewed;

- the lever is removed;

- the cartridge is changing;

- the mixer is reassembled.

Leakage in a two-valve structure occurs in most cases due to the failure of a non-ceramic axle-box crane; in this case, it is recommended to replace the axle box. Also, wear of rubber or silicone gaskets is often found in this type of device. To determine a breakdown, the assembly is disassembled (if it is ceramic).

Further, the repair process is as follows:

- the plug is removed from the valve;

- the bolt is unscrewed;

- the plug is removed;

- the valve is unscrewed;

- the axle box crane is dismantled;

- the causes of the malfunction are found.

Further, the assembly is reassembled, while new gaskets are installed. If water leaks at the joints of the shower hose, the reason is that the gaskets are worn out.

It should be repaired in this way:

- unscrew the fastening nuts;

- change gaskets;

- the thread is reinforced with FUM tape;

- all elements are reassembled in the same order.

- the most common problem is with classic two-valve bath mixers. They can have a movable spout, round or flat configuration. Malfunctions occur in most cases due to wear of the gaskets located under the fastening nut. The reason is always the same: too hard water.

Causes of malfunctions of contactless mixers

There is only one reason for this, because this type of mixer is considered the most reliable: there are no units subject to mechanical stress.

Manufacturers provide warranties for these devices for at least five years.

Repairing touchless faucets is always a challenge. Breakdowns in them most often occur due to the failure of sensors responsible for the flow of water. It is difficult to fix this kind of problem on your own; it would be wiser to delegate this work to a specialist.

It is highly likely that too hard water, in which there is an excessive amount of iron salts, can be the cause of the failure of the mixer.

The most common breakdowns:

- the water jet is very thin. The simplest fault that is easy to fix. Most often, this is observed when the aerator fails, this is a special device at the end of the spout. An aerator is usually made of metal or plastic;

- switching modes of water intake is difficult. In this case, the switching mechanism is repaired.

Useful Tips

- Both ceramic and rubber gaskets are suitable for the cores, they can be changed as needed. Silumin is an alloy of two elements: silicon and aluminum. Cheap models of mixers are made of this material, which are extremely short-lived due to their fragility. Sometimes you can find spectacular-looking faucets for a small price. Most likely they are made of silumin, it is not recommended to buy them, because it can spontaneously burst or fall apart.

- When buying, you should pay attention to the external chrome coating, for low-quality products it is often of poor quality.

- Brass faucets are quality products. It contains copper and zinc. The more copper in the alloy, the more likely the product will serve for a long time. It is recommended to buy just such devices.

- To correctly install the eccentrics, you should wind them up with a sealing flight. You will need at least 8 turns of electrical tape (much depends on the thickness and density).

- When tightening the nuts, it is not recommended to overtighten them, so as not to damage the gaskets.

- To check for leaks, after tightening the eccentrics, it is recommended to turn on the water. If there are no leaks, then you can continue to work.

- The taps with the gander turning can be mounted at different heights from 15 to 45 cm from the side of the bath. The installation must be carried out in such a way that the length of the shower hose is sufficient.

- A handheld flexible shower is essential and only the user can find the optimal length.

Tools Required:

- electric drill;

- hammer;

- pliers;

- adjustable wrench;

- nippers.

The phases of the mixer installation work:

- screwing eccentrics;

- installation of the main building;

- spout installation;

- shower installation;

- testing.

From the above, it can be seen that the installation of the mixer is simple. If you follow the instructions exactly, then all the work can be done in half a day.In the event that there is neither minimum skills for working with plumbing, nor the desire to deal with its arrangement and repair, you can always entrust the implementation of these tasks to professionals.

For information on how to repair a bathroom faucet with a shower, see the following video:

The comment was sent successfully.