Features of flexible water line

In the era of modern building and plumbing materials, you no longer have to puzzle over how and where to place a convenient and discreet plumbing system. The standard rigid tubing has been replaced by soft flexible hoses enclosed in a robust housing. These parts serve for many years, provided they are correctly selected and used.

Peculiarities

Flexible eyeliner has a number of features, among which the positive ones easily stand out. But negative nuances should also be mentioned in order to avoid an unpleasant aftertaste, waste of time, effort and money.

Pros of this flexible liner:

- complete tightness and protection against leaks;

- saving the area of the room, allowing you to install additional interior items or appliances without looking back at bulky pipes;

- ease in changing the location of an object connected with a flexible liner;

- refusal to use a welding machine;

- protection of the hose from water hammer (if a pressure surge occurs in the water supply system, high-quality flexible hose is protected from rupture and water leakage);

- ease of installation and operation (all basic work can be done independently).

Flexible hose is typically used for a variety of plumbing connections. Most often it is used in bathrooms (connecting a toilet bowl, mixer, boiler to water) and in kitchens.

With regard to negative evaluations of flexible hose, most often users complain about problems arising from improper installation of the hose. To avoid this, experts advise purchasing goods from only a well-known manufacturer. Also, a guarantee of good quality purchase will be a thorough inspection of the product while still in the store (before you purchased it).

When choosing, you need to pay attention to several important points.

- The weight of the eyeliner should not be lighter than a feather. If you pick up such a product in your hand, immediately put it back. In the best case scenario, this hose will last a couple of weeks after installation.

- The flexible hose should bend easily in different directions. If you have to make an effort to change the shape of the hose, you can safely put it aside and grab another, since this one is made of low-quality technical rubber, which can simply crumble from bends.

Another significant drawback is the low service life of the plastic fitting. In order to choose exactly the right eyeliner, consider the main characteristics of this product.

Specifications

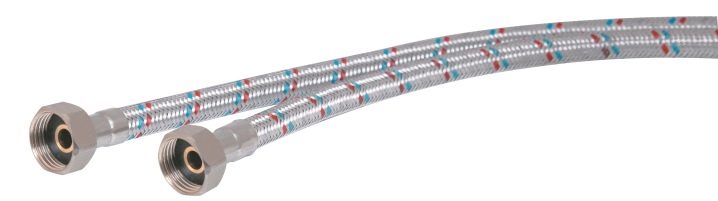

Today there are two categories of flexible water connections: extensions and adapters. The latter are standard hoses that connect the necessary devices to the water supply: sinks, toilets, showers and boilers. They are usually up to 60 cm long. Extensions are an auxiliary hose that connects to the adapter to provide water to the most remote areas.

The service life of any supply hose depends both on the starting quality of the product and on its correct installation and operation.

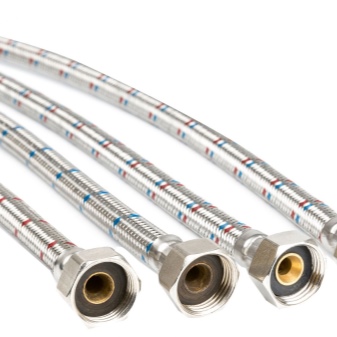

When purchasing a flexible bathroom liner, pay attention to the presence of colored stripes on the reinforced surface:

- red indicates the possibility of using only hot water;

- blue can only be used in cold water supply conditions;

- both stripes immediately indicate that the hose can be set to supply both hot and cold water.

Thus, when connecting a tap or toilet in places where only cold water is always used, all three types of flexible connections can be used. If we are talking about a mixer with two temperature modes, a boiler or a radiator, the use of hoses with a blue stripe is strictly prohibited here.

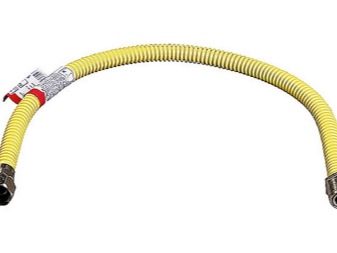

Flexible hoses with a yellow stripe along the entire length of the hose are also available. They are intended only for connecting users to the gas supply and have special impregnations and lubricants inside, which are unacceptable for use with water, especially drinking or for washing. The water passing through this hose is considered technical and contains impurities hazardous to human health.

It is worth dwelling on the main types of flexible hoses that exist today in the construction market.

Views

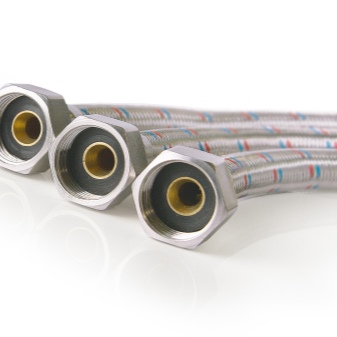

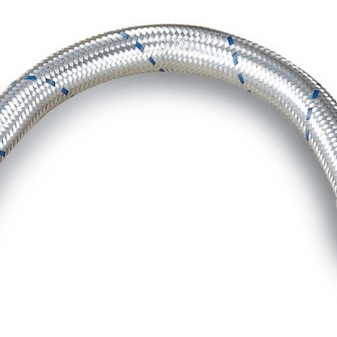

Modern manufacturers offer a wide range of connecting water pipes. They are classified according to the type of braid, internal filler (main tube), type, quality and size of fittings. Let's dwell on the most common division based on the type of braid.

According to the indicated criterion, flexible eyeliner is:

- reinforced;

- bellows.

The first is a rubber base (quality products are made from durable rubber), covered with a steel braid. In this case, the casing of such a hose can be made of different materials. For example, galvanized steel and aluminum take the leading place among analogues. This is due to the low price - and nothing more. Such a braid is absolutely short-lived, it practically does not withstand the average water pressure in the water supply system and breaks down very quickly. This should not be the case, because the upper skin of the rubber hose is designed to strengthen it and prevent water from breaking out.

In terms of quality and durability, a braid made of strong stainless steel wire is considered the best. It provides reliable protection to the inner rubber hose. According to manufacturers, the operational period of such connections reaches ten years or more.

The nylon braid is a reinforced plumbing treatment that can withstand even the maximum system pressure.

Choosing a reinforced braid for flexible hose, you automatically get the following benefits:

- installation speed;

- environmentally friendly materials of manufacture;

- high strength;

- flexibility.

The second type is an elastic stainless steel corrugation. Bellows hoses last longer and have better performance.

There are two modifications of corrugated elements:

- with an established length;

- with variable footage.

For the first, manufacturers immediately determine standard sizes, ranging from 20 cm to 80 cm. The step in the length of the product is 10 cm. The second has a floating range to which it can be stretched. For example, on sale you can find bellows liners with variable lengths of 150-250 mm, 200-350 mm and others. It is worth considering the fact that the maximum stretch is indicated for reference - it is undesirable to stretch the eyeliner so much.

The quality, strength and durability are evidenced by the use of bellows hoses for industrial purposes. Very often, this type of connection is used when connecting sprinklers - ceiling fire extinguishing devices. The main nuance is the plumbing system. A sprinkler installation is a whole network of pipes in which water is constantly under pressure. Therefore, the choice of an especially high-quality eyeliner material becomes very useful.

Among the disadvantages of bellows flexible liners are its noisy operation at high pressure in the water supply system. Despite the fact that this happens infrequently in modern apartment buildings, some users recommend using it as little as possible in private property.

Fittings are usually supplied with a flexible hose. These are often brass fittings or nuts that come in a variety of shapes and sizes. In order to choose the right mount, it is necessary to measure the diameters of the pipes in the room where the installation will be carried out.

Plumbing wiring used to be an ornate interweaving of pipes, tubes and adapters. But today, thanks to flexible piping, it has become possible to install devices using water supply in the smallest rooms. Angled flexible hose allows installation even in hard-to-reach places. Due to the peculiarity of its fastening, it can be located close to the wall and thus increase the usable area of the room.

Dimensions (edit)

The main parameters of flexible hoses are the diameter of the hose and its length. In this case, the caliber is important not only in the tube, but also in the fittings. For example, modern flexible hoses are manufactured with a maximum diameter of 1 to 2 inches. The most commonly used options are 1/2, 3/4 and 3/8.

As for the length of the reinforced or corrugated hose, each manufacturer has its own. In addition, it is practically individual for each individual case. If we are considering a stationary eyeliner, then the maximum length is 60 cm.In corrugated sliding models, this indicator can only start from the 500 mm mark, and finish within 5000 mm. The latter are extremely rare, mainly on an industrial scale.

Manufacturers: review and reviews

The most popular today are considered to be flexible eyeliners made in Italy. They have established themselves in the construction market, and many users are happy to note their advantages.

One of the most popular Italian trophy brands today is Parigi... According to customer reviews, the products of this brand have high strength. The manufacturer guarantees the service life of reinforced flexible hoses from 3 to 5 years, while bellows products can last more than 7 years. Italians pay special attention to details: fittings and nuts are made of high quality nickel and have a service life of more than 10-15 years. Product prices are high, which about 60% of users consider the main disadvantage.

Mateu Is a Spanish manufacturing company that has established itself as a quality manufacturer in the middle price segment. In sets of faucets for the kitchen or bathroom, you can often find flexible liners with a metal braid of this particular company. They also produce large quantities of their own brands for large construction hypermarkets.

Another feature of the Spanish manufacturer is the production of reinforced piping using PEX hoses. According to the descriptions of professionals, this type of hose has a maximum service life, since they are made of cross-linked polyethylene. The operation of such material in some cases reaches 50 years. Another feature of the PEX hose is its versatility: flexible connections with such a base can be used to connect both complex devices (for example, heating systems) and simpler ones (cold and hot water supply).

Domestic sanitary engineering is not standing still either. A large number of high-quality, but more affordable products are produced by manufacturers such as "Giant", "Monolith", "Aquatekhnika"... Users note a large number of advantages of these liners. But still, about 50% of respondents insist on the discrepancy of some of the technical characteristics indicated in the product passport, but on the whole they are satisfied with the purchase.

In order for each part to function correctly and as long as possible, it is necessary to strictly follow the rules for connecting and installing elements.Despite the fact that even a high school student can cope with this process, some expert advice should be taken into account during installation.

Connection rules

The water supply systems are connected to each other by means of special mounting fasteners. As mentioned earlier, these are fittings and nuts. The hose must be fastened freely, slightly sagging, therefore, when choosing a length, they rely on a large number. As for the fittings themselves, they come in different diameters (0.5-1.5 inches) and different shapes. If the water pipe and liner have different diameters, a special adapter comes to the rescue, which can be easily found in all plumbing stores.

Consider the basic rules for installing flexible water pipes.

- Before installation, or even better before purchasing, make a complete inspection of the fittings (fasteners). Check if the gasket is in place, in what condition the threads and braids.

- After installation, it is necessary to connect the water supply to the system and check the operation of the supply system for leaks within 30-40 minutes. If a leak does appear, try tightening the nuts a little tighter. But with this, you also need not to overdo it, so as not to spoil the mount.

- Bending of the hose is allowed in the ratio of no more than 5-6 diameters of the outer tube.

- The hose is very afraid of high temperatures, so try to avoid using the product in unfavorable conditions for it.

- Twice a year, it is imperative to check the tightness of the installation and inspect the external condition of the flexible hose.

- In the event of a shortage of hose length, a special extension can be purchased. To avoid metal corrosion due to electromechanical reaction, use pairs of the same material.

- Despite the service life specified by the manufacturer, it is recommended to replace flexible hoses at least once every 3-5 years.

Among the prohibitions, there are three immutable rules:

- do not use in continuous flow mode;

- do not install without gaskets or with visible defects;

- do not operate at low negative temperatures.

The scope of application of flexible liners is wide enough. One of the main rules here will be the appropriateness of their use in this particular situation. There are cases when similar products were used to connect fan coil units - elements of the air conditioning and ventilation system. Any flexible reinforced or bellows fittings for water have a wide variety of attachments. In the language of professionals, they are called: "mom" - "mom", "dad" - "mom", "dad" - "dad". "Mom" here is expressed with a union nut, and "dad" - with a long fitting.

In the process of installing a flexible water pipe, you cannot do without the recommendations and advice of specialists, especially if the installation is carried out by you yourself and for the first time.

Advice

Having decided on a flexible water liner, you run the risk, unfortunately, of buying a low-quality fake.

To prevent this from happening, here is a list of basic guidelines for purchasing a good product.

- Buy only from trusted retail outlets and well-known manufacturers.

- Reliable products are always completed with a passport with a description of technical characteristics (for example, the maximum pressure and temperature in the system that this hose can withstand), the period and rules of operation. Quality models usually have a designated shelf life of up to 10 years.

- In addition to accompanying documents, each product has special markings indicating the same technical characteristics, manufacturer, diameter, and more.

- All official brands put only certified items on the sanitary ware market.

- Due to their design, bellows connections usually have increased noise generation. But this can be avoided by purchasing such hoses with a special plastic coating.

- The best material for flare nuts and fittings is nickel-plated brass, and aluminum or steel-aluminum hybrid components last three times less - no more than 3 years.

- Sometimes in the process of screwing the liner, twisting and unnecessary bending may occur. Such moments should be avoided and the condition of the hose should be carefully monitored. Otherwise, this can lead to early abrasion of the rubber component and its quick replacement.

- When visually assessing the quality of the flexible hose, pay attention to the braid, which should be uniform, without burrs, protruding tails and other imperfections, and the fittings should be well crimped.

- The included rubber gaskets rarely last long. Perhaps there is a need to purchase more durable silicone or paronite products.

How to make it yourself

Folk craftsmen easily share recipes for making their own flexible eyeliner with a reinforced braid.

The parts of one of them include:

- flexible stainless steel pipe;

- device for cutting pipes;

- roller;

- nuts;

- rubber or silicone gaskets.

The technology consists in cutting off the required piece of pipe, rolling up both its edges, fixing them with a retaining ring, stringing nuts and installing gaskets.

There is nothing complicated in the process of installing a flexible water line., but there are a number of nuances in the selection of the necessary parts. Therefore, pay attention to all the little things even before paying for the product so that you do not have to go back and buy a new eyeliner.

See the following video for the features of a flexible water line.

The comment was sent successfully.