The device and options for manufacturing a shower cabin

The shower cubicle fits perfectly into the interior of the apartment and serves as an excellent alternative to the bathroom. It does not take up much space and saves time for washing. But often the boxes offered for purchase do not meet all the requirements that are so necessary - either they are too small, or the design and functionality does not suit. In order not to waste time looking for the right model, you can make a shower stall yourself.

Device and advantages

A hand-made shower stall may practically not differ from a purchased design. However, such a hydrobox will already meet all the requirements of its owner and fit perfectly into the room. And besides, if something suddenly goes wrong and a breakdown occurs, it will be clear what happened and what exactly broke down, because the whole structure, each bolt was selected and mounted with his own hands.

The decision to create a shower cabin, as a rule, is due to the fact that:

there is not enough space in the apartment, or rather, the bathroom is small, and a huge bathroom is an unaffordable luxury;

the house has a complex architecture with nooks, which can be "beaten" in such a way and equip a full-fledged washing place;

in a private house, you want to create an ideal corner with a "tropical shower", hydromassage and other technical innovations;

in the country or in the garden, you need a place where you can wash.

A person who understands plumbing and has done major repairs at least once can make a shower cabin himself. When arranging a box, you can cheat and install some of the completely finished parts: whether it be a pallet or walls with doors. Ready-made purchased structural elements will greatly simplify the entire assembly process, however, the decision to install them will slightly limit the possibilities of an individual project, adjust it to certain frames, because the finished elements have a strictly verified standard size.

There are several options for erecting a hydrobox:

Assembling a ready-made kit - just buy and assemble a shower on site without any preparatory work.

Installation of the cabin on a ready-made pallet or bath. Here walls are selected and decorated, plumbing equipment is installed. There is no need to prepare the floor (leveling is done only in case of obvious defects and differences in height).

Construction of a hydrobox based on a homemade pallet. At the beginning, a corresponding pedestal with sides is made, and then the installation and decoration of the walls is already underway. Walls and doors are either custom made or purchased ready-made.

Complete self-made hydrobox assembly, all parts are unique and homemade.

Construction of a shower structure without a pallet with ready-made doors and walls.

Construction of a hydrobox without a pallet with unique partitions and doors, made to order or by hand.

An independent cab device will not save you from spending money. If you choose low-quality and cheap materials, it may be possible to save money, but this money will still be spent on repairs.

Often, self-assembly can be even slightly more expensive than the purchased version.But it is worth it, as the ready-made kit will be fully functional, unique and practical.

The process of assembling a homemade shower stall will take place in several stages:

erection and preparation of walls; if the box is placed in a finished room, then this stage can be skipped;

construction of a hydro-barrier of walls and a pallet;

creation of a water drainage system with the ability to service all hidden plumbing;

laying of communications;

purchase of finishing materials and further wall cladding;

installation of walls and doors.

Wall requirements

The wash area where the cabin will be installed is a very humid place. Accordingly, the internal walls and corners will be heavily loaded. Mold, mildew, leaks (and, as a result, flooding) are the troubles that threaten the owners of homemade shower boxes who have not taken care of protecting the walls.

Theoretically (and practically too) the hydrobox can be installed near any walls. Even wooden ones. But they must be protected from moisture. Not all wood species are water resistant.

One of the ways to protect the walls is to additionally cover them with moisture-resistant plasterboard. Of course, additional treatment with moisture-repellent compounds will not hurt either.

In addition, they have good moisture-repellent properties:

walls lined with tiles (tiles or mosaics) and, if they are fixed on appropriate compounds, resistant to high humidity;

walls sheathed with PVC panels;

walls made of glass, brick, stone.

In addition, you need to take care of the ceiling, ventilation system, electricity. The top can be sewn up with panels or tiles, covered with plaster, which contains protective components.

It is advisable to conduct electricity outside of an area with high humidity. The optimal solution would be to install 12 W LED lamps. They do not get very hot, they are economical, but at the same time they light up the space well.

It is also worth considering that very often after taking a shower, soap and lime deposits remain on the wall surfaces. When choosing materials for their finishing, you need to understand that you will have to wash them often.

Materials (edit)

Any shower cubicle consists of several parts: internal walls and ceiling, external doors, partitions, a pallet (or a specially prepared floor area), as well as plumbing.

Walls can be built from any building material, but if they are made of wood (or other material unstable to moisture), then it is advisable to cover them with moisture-repellent compounds. Better yet, sheathe it with special drywall. And then glue it over with tiles (mosaics) or install plastic panels to implement the decorating idea and greater protection.

You can also build walls from glass blocks. This solution will create a warm and bright space.

When arranging a corner cabin, external walls can be made of polycarbonate, plastic, glass. Doors (both swing and sliding) can be made of the same materials.

The walls and partitions of the shower stall can be made of several types of materials at once. For example, they can be half bricked, and the second part will be made of glass.

The pallet is usually made from acrylic or enamel at the factory. For a homemade pallet, bricks are used (and, of course, a cement composition, screeds, as well as waterproofing - for example, bituminous mastic), but other materials can also be used (construction of a structure made of plasterboard, wooden formwork and monolithic concrete). In addition, a layer of insulation - expanded polystyrene - can be provided in a homemade pallet.

If the cabin is built on the base of the bathtub, then only doors and partition walls will be needed, which will act as a "curtain".

There is an option of constructing a hydrobox without any doors and external walls.Walls and doors, on the other hand, are replaced with a water-repellent fabric, a curtain.

When choosing building materials, preference should be given to those solutions and mixtures that contain special additives that increase resistance to high humidity, mold and mildew formation.

Models and shapes

Standard sizes of hydroboxes range from 80 cm to 1 m wide. In the first, there is very little space and quite uncomfortable. The meter-long booths are already more spacious, so you don't have to worry that some awkward movement accidentally knocks down cosmetics or shelves.

The advantages of home-made cabins are that they can be made of almost any size in length and width, height. But if the dimensions are still small, then you should strive for a figure of at least 90 cm. In such a hydrobox it will be possible to wash comfortably, but there will be nowhere to turn around.

In their shape, the booths can be both rectangular and square, as well as rounded. The rectangle and square are quite easy to reproduce when constructing a hydrobox on their own, in contrast to the rounded options. To recreate a semicircle at home, you need polycarbonate, which will need to be folded.

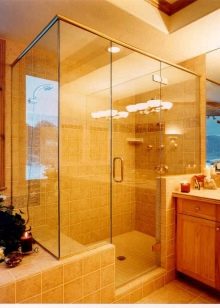

When determining the location in the room, they very often resort to such a booth option as a corner. It is built into the corner of the room, so the manufacture of internal walls is out of the question. They are already ready. The corner can be made in a semicircle, a trapezoid or at a right angle.

You can arrange the bath in the form of a shower stall. To do this, you only need partitions and doors. As a result, a space will appear in which you can not only take a shower, but also soak up the bathroom.

Determine the place

In a small apartment, every meter counts. Therefore, the decision to install a hydrobox is quite justified. The bathtub is removed, space is freed up for the washing machine and there is a space where you can change. It is important to take into account that the box should not interfere with movement around the room, create inconvenience when using other interior items (washbasin, washing machine).

In a private house, there is much more space for installing a booth. In addition, the space for the box can be thought out even at the design stage of the house. But if this was not done, then it may well be built after.

If the booth is installed in the country or in the garden, then it can be located where there is free space and access to water.

Choosing a base and a drain system

The fundamental decision in the self-assembly of a shower stall is the use or non-use of the pallet. It is from the foundation that all work on the creation of a hydraulic structure begins.

The choice of the base also determines which drainage system will be installed. The deep pallet, both self-made and ready-made, provides for laying pipes without bricking.

The palletless version implies a hole in the floor and a grooved channel into which water will go.

The use of a siphon is the simplest and most affordable solution for collecting and draining water. When using a pallet, the main thing is to provide access to the structure. The pipes should be laid at an angle of 30-45 degrees. The slope of the sewer pipes, which will help to avoid stagnant water, is two degrees per meter.

Arranging a ladder is considered a more reliable water drainage system. And besides, this system takes up less space in height. When installing the drain, it is also necessary to create a water seal, which will protect against the backflow of water and drains.

The simplest ladder consists of several parts: gratings, glass and the base itself with an opening for connecting the structure with a sewer pipe. Thanks to this structure, the possibility of blockage is minimized. Due to the fact that the grill is removed, there is access to the internal parts of the device.If you clean the parts in a timely manner, then you can not think about blockages. The shower stall is not a place where a lot of garbage accumulates in the drain. But if, nevertheless, a blockage has occurred, for example, at the entrance to the pipe, then it is enough just to push it into the pipe. When it is laid correctly, the blockage will go through it.

Installing a drainage channel is considered more difficult. But on the other hand, it has a large area for collecting water. The drainage channel can be installed in walls as well as in the floor.

The full functioning of the shower cabin is impossible without a specially equipped water supply. From an aesthetic point of view, it is better to hide it. The shut-off valves will be located away from the box in a separate recess. But still it is not worth bricking pipes into the wall. It is best to make a groove-niche in the wall and, after laying pipes in it, fill it with cellulose insulation (ecowool).

If the cabin is far from the sewer riser, then it is necessary to take care of the sewage pump. It is advisable to install pumps with solenoid valves.

Finished pallet

The use of a ready-made pallet greatly simplifies the process of box construction. It can be acrylic or enamel. Each of them has its own advantages and disadvantages. So, the acrylic tray feels warmer. But enamel is non-slip.

In addition, there are also trays made of copper, ceramics, glass. But such options are quite expensive, although they have a number of advantages.

The main disadvantage of any pallet is its standardization. It is difficult to choose a finished product according to your own individual dimensions.

The installation of the finished pallet is as follows:

first of all, the base is leveled on which the container will be placed, and a rough screed is made;

pipes are laid and plumbing is installed (ladder or siphon);

the finished product is installed and fastened.

Do it yourself

A homemade pallet is made of bricks. It is also possible to build a frame and its further plasterboard sheathing. But the use of bricks is safer. For its masonry, cement with special additives is used. If such additives are not at hand, then you can add PVA glue or water glass to the solution.

When the contour is laid out, you can take care of the rough screed. After that, cover with waterproofing in several layers. For these purposes, bituminous mastic is usually used. If insulation is needed, then the screed is laid in several layers - a small layer of cement mortar, insulation, screed, it is imperative to coat each layer with waterproofing.

The final layer will be a tiled covering - tiles or mosaics. They will provide a non-slip finish. The layer of adhesive should be small and, naturally, it should contain additives that increase resistance to moisture.

The construction of a homemade pallet begins with the manufacture of a frame, formwork or small brickwork. A ladder, funnel and pipes are installed in this space. For your information: the height of the wall of the pallet should be such that, after lining it, the knee of the drain, the concrete screed can fit there, and at the same time the slope is observed. During work, it is necessary to protect the plumbing and the ladder as much as possible from the ingress of construction debris. For the duration of the work, you can plug it with a newspaper or other paper. Do not neglect waterproofing and, having built a formwork or a brick side, you need to walk it in several layers along the walls to the height of the future screed. It is worth laying fastenings for the racks in the brickwork, if you plan to have glass (plastic) fences inscribed in a metal frame.

When the concrete screed is dry, you can start facing the sides and floor. And if up to this point the slope for water was not provided, then it can be done through finishing work. It is necessary to reduce the thickness of the tile adhesive. The closer to the funnel, the smaller the layer.

Some points regarding a homemade cast-in-place concrete pallet:

For a concrete pallet, insulation is simply necessary, you can also make floor heating (but this is a matter of taste and individual preferences).

In the process of creating such a pallet, waterproofing is also required in several layers and glued along the perimeter with a waterproof tape.

After the waterproofing layer, there is a layer of insulation along the walls. In addition, a damper tape is also laid around the perimeter.

Next, the expanded polystyrene is laid, the thickness of which is more than 5 cm. The joints must be connected with reinforced tape.

This is followed by a metal mesh with a 1 cm cell.

After the beacons are exposed, the slope is being formed, first half the solution to half the height of the screed. Moreover, the solution itself must contain a minimum of water. After that, the second half of the solution is laid, which is prepared according to all the rules. It can be aligned with a rule.

When everything is set, there is a layer of coating waterproofing, and then ceramic cladding. When erecting a hydrobox in a multi-storey building, it is worth breaking the screed layer into two and smearing each with waterproofing.

You will see how to make a homemade shower tray in the next video.

Without a foundation

Building the right shower stall space without a pallet starts with building a field. The main thing when arranging it is to provide a slight slope, literally a couple of three degrees, no more. The drainage system will be hidden in this case. But it is worth remembering that it is necessary to form a gutter with a grate with the ability to access it.

The design of a barrier-free space is best done when the screed is just forming in the room. This makes it easier to determine the height around the perimeter of the room.

The first steps in this direction will be the installation of sewerage and communications.

After that, the perimeter of the washing area is designed. A dividing box is being constructed at this site. With its help, it will be much easier to bring the level of the main floor to 0 degrees. The base for the booth can be made when the main screed of the room is already completely dry and grabbed. The angle of inclination in the wet area is small - 1-2 degrees. It is worth considering that when arranging a warm floor, the screed is created in two steps. The first layer is reinforced, waiting for setting, and then heating mats are placed on it. A second thin layer of mortar suitable for this purpose is applied to these mats.

When the subfloor is ready, it is necessary to waterproof it. After that, you can already proceed to finishing work.

Manufacturing of a corner and installation of fences

The shower cubicle-corner is the simplest in terms of construction. In fact, it is built into the corner, that is, the erection of internal walls is not required. You just need to think about where to place the hood. As a rule, it is designed on the interior walls.

Usually, the walls are made of tempered glass, covered with a special film that protects against splinters. In a private house or on the street, the option of erecting glass block fences is quite acceptable. They are made of glass, which means they will transmit light, but they will not show through.

Even as a material for the construction of partitions and fences, polycarbonate has proven itself well. Its indisputable advantage is that you can give it even the most intricate curved shape. With its help, the corner booth can be decorated in a semicircle.

A glass booth is unthinkable without doors. Built-in doors can be hinged, sliding, and there are also options for installing accordion doors. To install them, you need a certain set of accessories, which is attached to the frame.

All of these materials have good performance characteristics and can provide decent waterproofing.

To build fences, you will need to build a frame into which the main materials - glass or plastic - will be embedded.

You can assemble a corner or a simple booth with a pallet as follows:

First, make a frame. As a rule, such a structure is made of metal profiles, corners, guides. It will reliably hold fairly weighty glass or plastic. But if there is no need for a heavy frame and a light material is used, then its analogue can be made, for example, from nickel pipes.

Install a wall profile on the edge of the pallet, align it strictly vertically. Mark drilling points for subsequent fixing of the profile.

Make the required holes in the non-hammer drilling mode. Install the dowels into the holes and mount the profile.

Hang the wall panels. The gasket must not interfere with free closing, but it must adhere well to the base.

Secure doors and walls.

If you need to build a barrier-free space, then you need to know that doing it right is not an easy task. The main thing here is the installation and installation of the floor. But on the other hand, such a booth will delight for a long time with its modern design. In it you can conveniently arrange shelves, equip with a seat, put a good shower with a massage effect.

The sequence of work is as follows:

drill holes for mounting frame parts;

pin profiles;

install partition walls together with seals;

next is the fastening of the door frame;

installation of special fittings and installation of door (s);

booth sealing - all seams are treated with silicone sealant.

When the body of the shower stall is fully assembled, you can take care of the installation of the remaining plumbing fixtures: mixers, taps, shower heads. Soap dishes, handles, holders, mirrors and other fittings are attached through seals. And finally, you can connect the water supply, check everything for tightness, the presence of leaks. If the latter are not available, then we can say that the hydrobox is finally assembled.

Recommendations for use

In order for the shower stall to serve for a long time, it must be looked after - regularly washed and cleaned, ventilated, and then there will be no plaque and musty smell of stagnant water. It will not be superfluous to periodically check the performance of all hidden and explicit plumbing details of the structure.

Special treatment of the seams between the tiles will save you from the occurrence of such unpleasant phenomena as the appearance of black streaks, mold, mildew. It is also advisable that the booth is cleaned after each wash. It is enough to rinse the surfaces first with warm and then cold water, wipe dry with a towel or napkin. The main thing is to regularly inspect and clean the structure.

When cleaning plastic and chrome-plated surfaces, do not use active chemicals, coarse brushes and sponges. For glass surfaces, mirrors and glass cleaners are suitable. But for an acrylic pallet, a special tool will be useful. In the absence of such, a soap solution will help to cope with dirt. The enamel tray is more resistant to strong agents. A homemade tiled pallet can also be cleaned with strong or even abrasive substances, but the latter are best used only in extreme cases.

Keep your shower stall clean and tidy. Change the plumbing in time, and then the self-made hydraulic structure will last for more than a decade.

The comment was sent successfully.