Where is lining used in construction?

Interior and exterior decoration with wooden facing material remains popular at all times. This is due to the special surface and the aura that wood brings to the room.

One of the most popular and affordable types of lumber is lining, which is characterized by its versatility. Today, manufacturers annually replenish their product range, making it more and more high-tech.

What it is?

Clapboards are thin planed boards used for cladding surfaces. A similar name exists only in Russia, which is associated with the history of the appearance of the material. Initially, carriages were sheathed with wooden strips to protect them from rain, sun, and damage caused by rodents. Unlike iron, wood avoided the greenhouse effect, and was cheaper.

Over time, ordinary boards have acquired tenon grooves., thanks to which the installation has become easier and faster, the risk of deformations has disappeared. This idea was picked up by the builders, starting to use similar sawn timber for external and internal work.

Once in Europe, do not use the name "lining", but look for profiled boards. They are manufactured according to the DIN 68126/86 standard developed in Europe. This GOST is much more demanding on the quality of the material than domestic standards, and therefore the products of European brands are better both in terms of quality and installation methods. Buyers from Russia are familiar with such finishing boards as "Euro lining".

It is important to distinguish lining from MDF, since the latter, being a material "glued" from wood chips, significantly loses in its technical properties.

So, answering the question of what kind of lining is, we can say that the material is divided into lining and euro lining. Moreover, buyers have many complaints about the first: too high humidity (20-25%), an increased percentage of board deformations, as a result of which small locks often pop out of the groove. Finally, the hairiness of the material and the number of knots are not controlled in any way, which affects the aesthetic properties and ease of use of the material.

Against the background of the lining, the Euroboard has a number of advantages:

- Reasonableness of forms (optimal width and thickness of the lamellas, which eliminates problems with the spike, which is also larger in size), the presence of ventilation grooves for condensate drainage, the ability to choose the texture of the material.

- Lack of lint on the front side of the material, as well as in the area of the thorn-groove, which ensures ease of installation and use, the visual appeal of the material.

- The moisture coefficient is 10-15%, which eliminates the risk of deformation, the appearance of grinder beetles in the wood.

- A more detailed classification of the material depending on the manufacturing defect, the characteristics of the wood.

The description of the material will be incomplete if you do not indicate that it provides good heat and sound insulation, since an air gap forms between the lining and the surface to be finished. In addition, the loose joining of the boards gives the walls the opportunity to "breathe", and therefore there is always a pleasant and useful microclimate in the room. Boards can be mounted horizontally and vertically and must be periodically covered with protective materials.This will provide a long - up to several decades, service life.

Moldings (that is, products based on post-processed sawn timber) have a unique pattern on the wood, a light forest aroma, a variety of color palette - all this allows you to implement the most unusual design solutions.

Peculiarities

The material is based on natural wood (oak, linden, aspen, larch, pine, etc.), which explains its environmental friendliness, the absence of emitted toxic compounds. The advantages and disadvantages of the lining are determined by the peculiarities of natural wood.

The advantages of the material are:

- versatility of use - the material is suitable for both external cladding and interior design;

- strength and long service life;

- lack of deformation under the influence of moisture and temperature changes (to a greater extent, it is true for euro lining);

- with regular processing, mold does not appear on the surface of the material, it does not darken even in high humidity conditions (which is why boards are used to decorate baths, saunas);

- favorable indoor climate;

- high thermal insulation properties;

- good sound absorption;

- aesthetically attractive result of facing, originality, originality and uniqueness of the wood pattern, richness of the color palette;

- ease of installation - having studied the general principles of laying the material, you can proceed to self-installation without resorting to hiring professionals;

- ease of care;

- affordability.

The material has a wide range of uses and is suitable for the following types of work:

- facing of saunas, baths;

- interior decoration of residential and utility premises;

- facing of loggias, balconies, terraces, verandas;

- door decoration;

- decoration of stairs and passages;

- external wall cladding using thermal insulation materials.

The main disadvantage of the lining is low fire safety. This feature can be leveled by impregnating the material with fire-fighting compounds.

Finally, it is important to remember that in order to preserve the technical and aesthetic properties of the material, it must be regularly treated with protective compounds.

Types and varieties

The division of material into types and grades is based on the difference in visual and scope of application. At the same time, different types of lining differ in size and shape, bevels or their absence, and the features of fasteners.

There are the following types of profiled boards:

Traditional

The outer part of the material has an additional chamfer in the area of the spike, and therefore, after assembling the material, the surface has noticeable seams. Allocate angular chamfers (lining "Kolkhoz Woman") or rounded. The latter are called Soft-line.

Soft-line

A panel with no corners and rounded ends. This avoids the appearance of chips and burrs on the sheathed surface, and therefore the material is often used for interior decoration.

"Calm"

There is no chamfer on the panel near the spike, so the finished surface is smoother, without pronounced seams. The material is suitable for imitation of a wall from a bar, it can be produced thickened up to 25 mm and is suitable for outdoor use.

Land House

It is characterized by high attractiveness, since the front side of the panel has complex patterns. They are obtained by milling or other methods. There are cladding lamellas that imitate wood carving, which is achieved by hot stamping under pressure.

This type of boards is characterized by a higher cost.

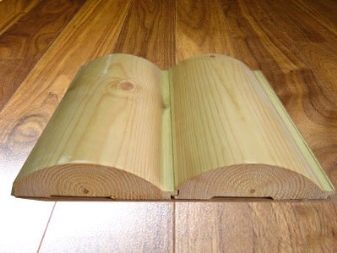

Block house

The front side has convex rounding, therefore, in the assembly, the material imitates the surfaces of rounded logs. The design features are due to the improved heat and sound insulation characteristics of this type.

"American"

Simulates siding panels due to the smooth transition from the tenon to the middle part of the outer surface of the lamella and the absence of a chamfer near the tenon.With a thickness of 20 mm and a board width of 140 mm, it is ideal for outdoor cladding.

"Peasant"

Provides smooth, almost seamless surfaces, and therefore is actively used for interior decoration, including ceiling decoration. Based on the dimensions and features of the fastening, they distinguish suture (thinner lamellas, the ability to sheathe any surface) and seamless (thicker panels, differing in the richness of the choice of shades) modifications.

Bilateral

Its main feature is the absence of front and back sides, which makes it possible to use lamellas for the construction of wooden partitions. For external or external cladding, the user can choose a more attractive, defect-free side to be placed on the outside.

The material does not have ventilation perforations, and therefore is not suitable for use in rooms with high humidity.

Traditionally, lining is associated with wood, but today there is also a plastic version. It is based on polyvinyl chloride. The material is resistant to moisture and other atmospheric influences, long (up to 30 years) service life. However, plastic panels are less durable and, of course, they do not give the effect of naturalness, proximity to nature, uniqueness of color that wood models give.

The criterion of aesthetic appeal comes to the fore, and not the strength of the material, you can recommend brushed lining. This type has a characteristic relief and texture and is used to create unusual interiors. Brushed Euro lining is made exclusively from conifers.

Another type of aesthetically designed panels is embossed lining. On the surface of the panel, using the method, we go with chasing, 2 or more patterns are applied. To a greater or lesser extent, they are pressed into the panel, which provides a certain stylistic effect.

Finally, there is brick clapboard, also used for decorative finishing. The board imitates brickwork and has another name - wall parquet.

Depending on the dryness of the material, different variants of lamellae are distinguished. Optimally dry lining has a moisture content of no more than 12-15%.

Each of the considered types of lining belongs to one or another variety. Such a division is based on the state of the lining after it has been cut and dried. At the same time, the presence of cracks and knots on the lamellas, resin pockets, areas of unevenness (poorly processed zones) is assessed.

At the same time, there is no single standard for dividing into varieties, therefore each manufacturer uses different GOSTs or develops its own technical conditions (TU).

The following types of lining are distinguished:

- Extra. The material of this grade is also called knot-free, since only 1 knot is permissible per 1 running meter, without characteristic chips and cracks around and over the entire surface. If there are resin pockets, they are opened, the resin is removed, the resulting voids are putty and rubbed with fine sandpaper. The resulting profiles do not require additional processing and are premium decorative materials.

- Class A. Profiles of this class can have up to 2-3 knots per linear meter, small chips. The front side of the lamellas may have small cracks (some manufacturers putty them) and areas of unevenness. If the profiles are made of conifers, resin content is allowed (no more than 10% per pariah). The colors can fluctuate within one tone and differ slightly on every tenth profile. Suitable for flooring, ceiling decoration.

- Class B. One panel can have up to 2 knots, cracks no more than 3 cm long on the front and end parts of the board. On the surface of the edge, the presence of fallen knots, the diameter of which does not exceed 20 mm, is permissible. The panels are often made from a core and have resin pockets.The presence of areas damaged by insects is allowed, but the percentage of the latter is no more than 5%. Areas of unevenness and blueness (an indicator of a violation of the drying technology) are possible, if they do not cause the panel to become unstable.

- Class C. All other profiles suitable for finishing fall into this category. It is unacceptable to include only rotten and unstable boards in this grade. Otherwise, the following defects are allowed: the presence of knot holes with a diameter of more than 20 mm, through cracks, chips, guminess, the presence of blue and color mismatch.

Material

The classification of the lining can be carried out taking into account the type of wood used for the manufacture of profiles. The panels can be based on the following tree species:

Conifers

For lining made of needles, the presence of a large amount of resins and essential oils is characteristic, which prevents the damage of the material by insects, and increases the resistance to moisture. After demineralization, the boards are used for exterior decoration, cladding of baths, saunas (except for steam rooms) and other rooms with high air humidity. Needle panels have been in operation for a long time - up to several decades.

- Spruce is characterized by an attractive texture without pronounced patterns, lack of roughness, its use will be successful in rooms in a modern style. Since it is a soft type of wood, usually rounded lamellas are made from it. During installation, remember the high hygroscopicity of spruce boards, which must be treated with protective compounds.

Among other advantages is affordability.

- Pine profiles are even more affordable in terms of price. The material also has an attractive texture and is suitable for both exterior and interior decoration. The only thing is that the use of pine lining should be abandoned in places where there is a risk of damage to the material. The fact is that it is vulnerable to impacts and scratches, since it has a low density. In addition, the profiles emit resin for a long time during operation. In this regard, it is unacceptable to use them in the bath, because leaning against the hot resin on the surface of walls or shelves, you are guaranteed to get burned.

- If we consider more expensive materials, then this is larch, the high price of which is associated with the best operational properties of the material. Due to the peculiarities of the structure, it has increased thermal insulation capabilities and a surprisingly attractive texture and pattern. A feature of larch lining is a noble reddish tint.

- Another good heat insulator, which also has increased strength, is cedar. The boards made from it have a noticeable resinous aroma, which has a beneficial effect on the human central nervous system, and also repels mosquitoes.

Hardwood

They have a shorter service life, but they have a higher coefficient of thermal insulation. They are mainly used for interior lining of baths and saunas, since even at high temperatures they cannot cause burns.

- Among the materials that differ in price availability is linden. However, it is worth noting the high strength of the lining, resistance to mechanical stress and shock, and increased moisture resistance. The disadvantage of the material is its tendency to darken after some time of operation.

- Alder is also resistant to moisture, which, when heated, also releases tannins that are healing for the body. It is not surprising that it is often chosen for decorating baths and saunas. The advantage of the material is improved sound absorption, good thermal conductivity and authentic recognizable colors. Of the "minuses" - a shorter service life.

- Birch is suitable for interior decoration, but only in very dry rooms, since it is more susceptible to moisture and decay than other types.

- Oak lining is considered a classic, which is distinguished primarily by the unsurpassed strength of the material. It is also suitable for use in wet areas and also for outdoor use. Ash has similar properties.

Exotic breeds

As a rule, we are talking about redwood, which is mainly harvested in tropical regions. The resulting material is distinguished by its versatility, high strength and moisture resistance, unusual pattern and rich color palette. Naturally, the cost of such boards is significantly higher.

Size and packaging

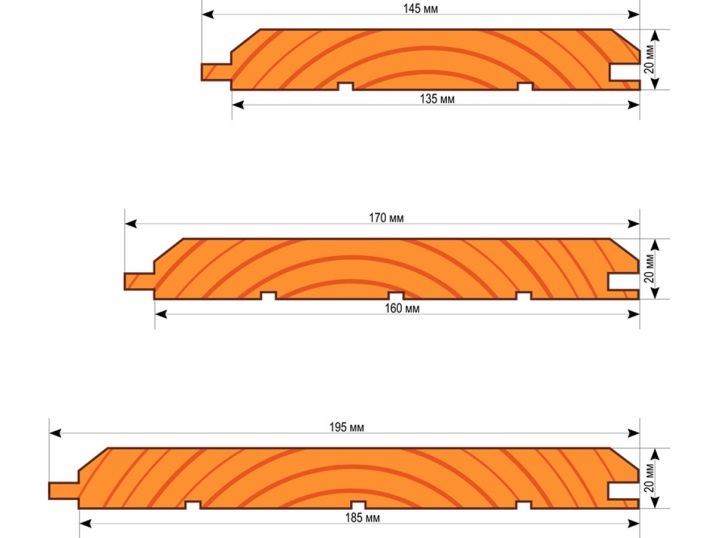

The lining is produced in many sizes, which is due to the scope of application, installation features. The length of the material ranges from 0.5-10 m (the standard length for domestic material is 2, 3, 6 m; for euro lining - also 50 mm), the step is 10 cm.

The lamella width is usually 80-200 mm. A wider lining is more susceptible to deformation during temperature "jumps". The narrow strip is resistant to temperature changes and mechanical damage. To achieve a certain stylistic picture, lamellae of different widths are often alternated. This does not in any way affect the strength characteristics of the finished surface.

Designers recommend using a wider board for larger areas. If the goal is to visually "raise" the ceiling, then vertically fixed narrow lamellas will do.

When calculating the required number of lining, you should take into account not the total, but the useful width of the board. As a rule, it is in the range of 80-88 mm, and in a wide version it can reach 190 mm.

When choosing the width of the plank, it is important that it matches the thickness of the material. This is the only way to achieve optimal strength indicators. Ideally, if the width and thickness of the boards are in a ratio of 1: 6. For example, ideally, a 150 mm wide board should be 6 mm thick.

The thickness of the lamellas for interior work is 12.5 mm, which provides the best ratio of strength and weight of the material. For outdoor decoration, it is better to take thicker profiles, the thickness of which is 15-20 mm. Such boards will support not only their own weight, but also the weight of the heat-insulating material. Although their cost is, of course, higher than their thinner counterparts.

According to the national GOST, the thickness of the lining can be 15-25 mm. If we turn to the European DIN standard, then the thickness of the produced Euro lining can be 13, 16 and 19 mm.

Returning to the height of the profile, it is worth noting that it can be made from a single piece of wood or by splicing. The last method involves joining boards with a height of 150-750 mm into one profile by joining on a microthorn and additionally gluing the joint. The connection is strong, since the profile is cured under the press until the adhesive is completely dry.

However, the inability to find out what kind of glue was used makes buyers refuse to purchase spliced lamellas for interior decoration. This is due to the risk of release of toxins from the glue when the boards are heated.

As a rule, spliced models are heavier and more expensive, which is associated with the technological features of splicing, as a result of which it is impossible to produce boards thinner than 15 mm.

The weight of the material depends on the type of wood used. For example, a square meter of ash weighs 11 kg, while the same volume of poplar is only 5.7 kg.

The standard number of lamellas is 10 pieces per package, while in class A material, up to 20% of class B boards are allowed.

The form

The shape of the lining is directly related to its appearance. Most of the material is in the form of a wooden bar (standard lining panel). A similar flat, but externally more perfect surface can be obtained using Euro lining. The maximum smoothness and perfection of the bases will be ensured by the installation of the so-called calm lining.These options (can be narrow and wide) in most cases are used for interior decoration.

A round lining, imitating a rounded log, is called a block house and is used for external and internal work. Stylization like a log surface is achieved due to the semicircular shape of the face of the lamella. The width of the "logs" is in the range of 90-190 mm and depends on the thickness of the material.

Colors

One of the advantages of eurolining is its unique woody shade and unique pattern. The color of the panels is primarily determined by the type of wood from which they are made. Linden has a beautiful natural shade, but it darkens quickly during use. The standard of beauty is considered to be eurolining made of mahogany and ash. Pine lining is distinguished by a warm golden tint, and larch boards have a noble reddish tint.

However, after several years of operation, natural wood begins to darken., its appearance ceases to be attractive. The situation can be corrected by bleaching the panels with the help of special products. However, the procedure will have to be carried out regularly.

It is much wiser and more profitable to initially cover the surface with a transparent varnish. The latter does not change the color and pattern of wood, but protects them, emphasizes the natural play of color and texture features.

In addition to varnishes, you can use impregnations and stains. Both types of materials serve to protect the profiles, but the stain makes the surface a shade darker.

If a colored lining is needed for a particular style of interior, they resort to painting it with decorative compositions. As the latter, oil and acrylate paints, acrylic aqualaks, decorative glaze can be used.

With the help of colored panels, you can achieve this or that stylistic effect. So, light beige, sand and white vertical panels visually stretch the space. Bright fragments will become the accent of the room. Do not forget that the colors of the floor and ceiling coverings must match each other and the shade of the walls.

Style and design

Depending on the method of fixing the panels, you can change the decor and appearance of the room. The simplest option for the location of the profiles is horizontal and vertical. The use of vertical thin stripes allows for a high ceiling effect.

To make the room more dynamic, to focus on the surface allows laying the Euro lining diagonally. The alternation of thin and wide panels allows you to create an original and memorable room. In this case, a 3D drawing is achieved - a herringbone, bricks, a chessboard, steps. Furniture should be matched to the shade of the lamellas and simple geometric shapes.

Rooms look no less stylish, where only the lower third of the wall is trimmed with clapboard, while the rest is decorated with wallpaper, painted or plastered. The border between different textures is closed by molding. In addition to aesthetic appeal, this type of design is of practical importance. As a rule, in the lower part, the plaster and wallpaper are quickly rubbed off, acquiring an untidy appearance. The use of lacquered lining solves this problem. A great option for a nursery or hallway.

Finally, accentuated use of panels is widely used. They finish off one of the walls or part of it, becoming a "feature" of the interior.

Painted lining makes up a large group of material, which allows you to recreate a particular interior. So, a panel painted in dark or black is used in classic living rooms and offices, while a pastel counterpart is suitable for Provence-style interiors.

Selection and application

If you want to choose a really high quality material, buy a lining.In this case, when determining the grade, be guided by the material, the classification of which is made according to the DIN standard. Please note that class C profiles are not suitable for finishing.

Evaluate the evenness of the lamellas. Even a slight bend is unacceptable. This indicates a violation of storage conditions. Arcs usually have panels stored in plastic wrap. The "correct" Euro lining is stored in a package. Do not be afraid to ask the seller to unpack the batch, do not agree to evaluate the material only by the first and last lamellas in the package - they are always of impeccable quality.

Be sure to evaluate the drying quality of the material. The higher it is, the more durable the panel will be. It will not lead during installation and operation. To determine the quality of drying, there is a special device - a moisture meter. For lining with natural humidity, an indicator of 20% is admissible, for euro lining - 12% with relative humidity.

Check the quality of the joint before buying. To do this, connect 2-3 lamellas together, there should be no gaps between them. The docking process itself should not take much time and effort.

It is believed that the material from wood growing in the northern regions is of higher quality. This is due to the fact that in harsh climates the growth of wood is slower, which means that its strength is higher.

For cladding internal surfaces, thinner lamellas are used from wood and coniferous species, in baths and saunas, only deciduous varieties are usually used. This is due to the fact that when the panel is heated, resin is released from the needles. It can cause burns if heated. For exterior decoration, lamellas of cedar, larch, oak of increased thickness are used.

How to process?

The lining itself is a fragile and short-lived material that is susceptible to fire, moisture, dust and insect pests. These disadvantages can be leveled out by processing the surfaces of the lamellas.

The lining inside the house should be covered with fireproof impregnations. Biosecurity of the material both inside and outside the premises will be ensured by the use of a primer. This antiseptic treatment is especially important for those panels where there are already traces of woodworm damage. The primer does not change the color and texture of the profiles.

You can increase the moisture resistance and preserve the natural shade of the boards using varnish. Surfaces can be treated without preliminary priming, since the varnish already contains antiseptic components. The varnish treatment gives the surface a semi-matt shine, which emphasizes the depth and variety of wood color, allows wet cleaning, and protects from the effects of temperature extremes.

When choosing a varnish for interior work, give preference to water-based formulations - scuba diving. They do not contain organic substances, and therefore are environmentally friendly, dry quickly and do not have an unpleasant odor. For external surfaces, purchase varnishes with water-repellent components. This surface will repel dirt and dust particles.

It is unacceptable to treat panels in a bath with varnish; under the influence of high temperatures, it loses its properties and can emit toxic fumes. Use a hot room scuba instead.

To protect against moisture and wood pests in the dressing room, you can use drying oil. For the steam room, you should buy special impregnations of universal action - they increase the fire safety of the material, protect them from moisture, and contain antiseptic components.

An important point - the processing of the lining in the bath is carried out before its installation. According to the technology, it is necessary to process the crate and panels before installation and again after installation.

Manufacturers and reviews

Brands such as:

- Lunawood - This Finnish company is a recognized leader in the production of thermowood.Lamellas that have been treated with high temperatures and steam acquire increased resistance even to harsh environmental conditions, damage, and decay. The brand's products are widely represented in the Russian Federation, and pine is the main material for production.

- Domestic manufacturer "Astar" boasts a high quality material and a variety of options for euro lining. They have materials of all classes from "premium" to C. As for the types of panels, there is also a wealth of choice. Only lamellas of the Soft-line series, which are characterized by rounded corners, are of about 10 variations!

- The company's products also received positive reviews. "Vyatskaya pine"... Production is carried out on German and Italian equipment, and therefore the products are of high quality.

- The leader in the production of sawn timber is the domestic brand PromMax... Leading here is the production of euro lining from aspen, spruce and pine. Buyers note the optimal combination of high material reliability and affordable cost.

Successful examples and options

The statement that clapboard trim looks good only in the country and in a country house in a "rustic" style is considered erroneous. The material combines well with other textures and, when used correctly, looks great even in high-tech interiors.

- Noble wood is ideally combined with plaster, wallpaper, tiles. Combinations like these make it easy to create a cozy classic or calm modern interior.

- Of course, the clapboard trim looks as organic as possible in country style. In an apartment, you can create such a corner in the dining room or living room. Preference should be given to the profile of light natural shades.

- And if you paint the panels in warm pastel shades, they will perfectly fit into the Provence style. Don't forget to complement the interior with plastered walls and rough wood floors.

- Wood panels are indispensable when creating a Scandinavian style. For it, choose light, bleached materials. The lining is used here for wall and floor decoration. Don't forget the wooden beams on the ceiling. And so that the room does not look boring, "dilute" the wooden surfaces with stone textures.

- Artificially aged lining in the finish is one of the hallmarks of shabby chic. It will look organically in small living rooms, attic, bedroom. In the bathroom, a light vertical or horizontal lining looks good.

- In modern interiors such as hi-tech, wood profiles are a backdrop that does not attract attention. For this, the panels are painted in white or beige, sometimes silver.

How to sheathe a balcony with clapboard, see the video below.

The comment was sent successfully.