Choosing clays for lining

Clapboard clamps are a convenient and durable type of fastener. The simplicity of their design and ease of installation allow you to clad the walls yourself and in a short time.

Peculiarities

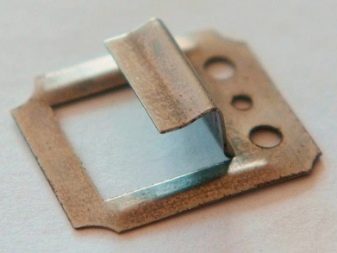

Kleimer is a bracket, for the manufacture of which galvanized iron or spring steel is used. The design of this hardware provides for the possibility of reliable fixing of the lamellas of the lining. Fasteners ideally match the shape of the slats with the tongue-and-groove locking system. Kleimers are also used for fixing Shtil MDF boards and plastic panels.

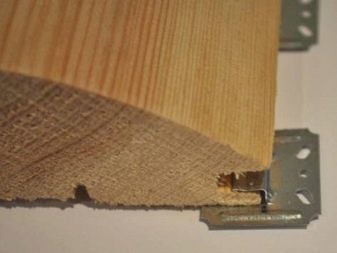

On the surface of the bracket there are holes provided for fixing the hardware on a rough base or crate. Fasteners are carried out using nails, self-tapping screws or screws and depends on the material of the work surface. Each kleimer is equipped with deep hooks, with the help of which the board is strengthened. Some models are additionally equipped with spike hooks that strengthen the fixation of the material and provide additional strength of the fastener.

Claymers are produced in a wide range with a wide variety of varieties and standard sizes, which greatly facilitates the choice of the necessary hardware and systematizes the model range. The classification is based on the height of the tongue and the thickness of the clasp. The minimum height is 1 mm, the maximum is 6 mm. The most common are staples with a tongue height of 5 mm.

This type of hardware is considered universal and is suitable for many types of lining. For the installation of euro lining, it is better to use a size of 4 mm, and for cladding with a block house - six-millimeter models.

Also, kleimers come with two- and three-millimeter tongues and are designed for attaching plastic panels and thin lining.

Advantages and disadvantages

High customer demand and popularity of kleimers due to the many undeniable advantages of this type of fastener.

- The simplicity of the design and the uncomplicated installation process allow you to independently perform the facing of the room without resorting to the services of specialists, and the exact observance of the installation technology will significantly reduce the time of work.

- The use of staples excludes drilling, nailing and other mechanical impact on the lamellas of the lining, due to which the appearance of cracks and chips becomes impossible. This is one of the advantages of using fastening clamps before mounting with screws, nails and screws.

- A large size range of models allows you to form a neat seamless coating even when using the technique of combining the lining with other finishing materials.

- Reliable fixation, which is achieved with the help of clamps, completely eliminates the risk of deformation and shear of the coating.

- Claymers are highly resistant to aggressive environmental influences and high humidity, so they can be used both in freezing temperatures and when decorating baths and saunas.

- Comfortable cost. The price of kleimers compares favorably with the price of other types of hardware.

- The versatility of the design allows the use of brackets when installing the lining on any rough surfaces, including wood, concrete, cinder block, cement bases and lathing.

The disadvantages of clapboards for lining include insufficient reliability under the influence of increased loads or foundation vibrations.

Therefore, in areas with seismic activity, reinforced fasteners should be used for cladding.

How to choose?

Finding the right hardware is very simple. The main condition for this is the selection of the required size, which is determined by the type and width of the lining. Attention should also be paid to the integrity of the galvanized coating, since the corrosion resistance of the staples will depend on this. Self-tapping screws should be purchased at the rate of 2-3 pieces per kleimer. Fastening hardware with one screw is unacceptable - momentary savings in the future will provoke deformation and shift of the lining.

In order to select the required number of cleats, simple calculations should be made: on average, you need to purchase 20 staples per 1 sq. m of surface. It should be borne in mind that when finishing a flat area, the step between adjacent hardware should be 45 cm, when facing the outermost zones - 35 cm, and when installing the lining in the corner sections, the step length will be 25 cm.

The larger the size of the parts, the longer the step, and, accordingly, fewer parts will be required.

Subtleties of installation

Installation of cleats is carried out using a screwdriver, a building level, a tape measure, a square, a hammer, a screwdriver and a marker. The first stage of work should be the preparation of the working base by leveling the surface or, if necessary, installing the lathing. The evenness of the base is determined using a laser or a building level. All protruding parts must be removed, and large cracks, chips and deformations must be eliminated using a cement-sand mixture.

To form the lathing, you need to use a frame made of wood or metal with a step not exceeding 0.5 m.

After that, you should make an antiseptic treatment of the base and wait until the surface is completely dry. Then you can start marking the installation locations of the cleats. It should be borne in mind that with the vertical arrangement of the rails, the installation of hardware should be planned at a distance of the width of the board from the adjacent wall. With a horizontal arrangement, you should step back from the floor 2-3 mm, necessary for screwing in the self-tapping screw. Particular attention should be paid to the clarity of the location of the first element, since the correct installation of all subsequent strips and the appearance of the cladding as a whole will depend on it.

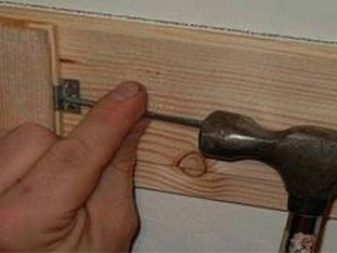

The installation of cleats and lining strips occurs alternately, so the main thing is to strictly observe the installation order and monitor the parallel arrangement of the elements. The use of nails as fixing elements for the bracket is permissible only in the case of installation on a wooden crate. In all other cases, self-tapping screws or dowels should be used, depending on the size of the bracket and the weight of the wooden planks. Then you should proceed with the installation of the cleats, while it is necessary to ensure that the board lies flat: without shifting to the side and violating the general order of laying.

In order to facilitate screwing in the screws, you should first mark the necessary places with dots. After installing the first brackets, it is necessary to proceed with the installation of the lining, simultaneously fixing the following brackets. The first lamella is inserted into the hook of the staple, and then the subsequent lamellas are slotted into the ridge. The next bracket should not be fixed until the absolutely level position of the first panel has been determined. The end part of the lamella, equipped with a ridge, must be pressed tightly to the base, and at this time, insert the clearer into the groove from the back side and fix it with self-tapping screws.

Following this installation technique, you need to complete the installation of the material, periodically checking the readings of the building level. After installing the last board, it is required to close the metal fastening elements with a wooden side.

Dismantling, if necessary, is carried out in the reverse order.

Useful Tips

Compliance with the following simple rules will extend the life of the lining and will retain its original appearance for a long time:

- kleimers should be purchased in specialized hardware stores, which will eliminate the risk of counterfeiting and prevent corrosion and quick failure of the fastening brackets;

- in order to avoid the appearance of rust and the destruction of hardware, it is not recommended to use liquid sealants to form joints;

- after the completion of installation work, the lining should be covered with a varnish, oil or wax composition - such a coating will help protect the material from the aggressive effects of sunlight and excessive moisture;

- when installing the lining, direct contact of the lamellas with the base surface should not be allowed - this can adversely affect the ventilation of the walls and cause the formation of fungus and the appearance of mold;

- cutting holes for sockets and switches should be carried out using a flared saw immediately after cladding, before applying varnish or wax;

- the space left near the floor is hidden with the help of a decorative skirting board that matches the color and texture.

Using a clapboard for lining as fasteners, you can in a short time independently produce a beautiful and effective finish of a house, apartment or bathhouse.

Due to their reliability and simple design, the brackets can serve for many years without the need to replace elements.

You can find out the fastest way to mount a race in the video below.

The comment was sent successfully.