Choosing cutters for lining

If the interior appearance of your home leaves much to be desired, you want to make repairs, but just gluing the wallpaper is already boring and completely uninteresting. Then clapboard wall cladding will be an excellent solution to your problem. Do-it-yourself wall cladding with decorative boards will be an ideal creative solution for you, and the use of lining will reduce your time looking for materials for cladding. You can choose the materials for repair yourself, the lining can either be purchased with a ready-made, processed board, or you can process it yourself, however, for this you need at least minimal skills in this area, as well as a special planer with which you can make such boards ...

What are cutters for?

In order to sheathe the walls, it will not be enough for you to use only special boards; in addition to them, you will need to purchase a manual router, as well as attachments for it - cutters. A milling cutter is a special attachment for a tool that has any shape, on which teeth are applied, which, when rotated, exert a mechanical effect on the object. With the help of these teeth, you can cut various objects, process them, grind and so on.

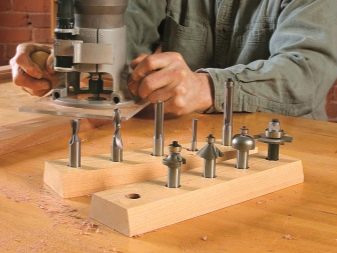

On the modern market there is a huge selection of different attachments, the main ones are:

- end;

- edging;

- cylindrical;

- disk.

End

Wood end mills are of one piece design in many cases, multiple types are rare. Such nozzles work mainly on the principle of the load exerted on the wood by the side edge. In addition to forming joints on planks, end mills can be used for end machining as well as for creating intricate patterns on wood.

Edging

This type of cutter is the most popular among craftsmen, these attachments are designed to form the edge of the board. Due to the peculiarities of their structure, edge cutters can create edges of various intricacies without going deep into the wood.

Cylindrical

This type is divided into several types:

- tapered - used to create carvings on wood;

- spiral - needed to make the edge of the board;

- groove - designed to create grooves of different shapes and types.

Disk

They are the most convenient for creating and processing facing boards (lining).

Disc cutters are used for different purposes:

- for processing lining;

- for panel processing;

- for processing and grinding stone;

- for metal;

- specialized attachments for various wooden products.

Mills for manual work with clapboard, in turn, are divided into 3 types:

- bearingless;

- bearing;

- edging.

When making the board itself, you will need bearing or edge cutters; for detailed processing, bearingless nozzles are suitable, for which you will need to purchase specialized equipment.

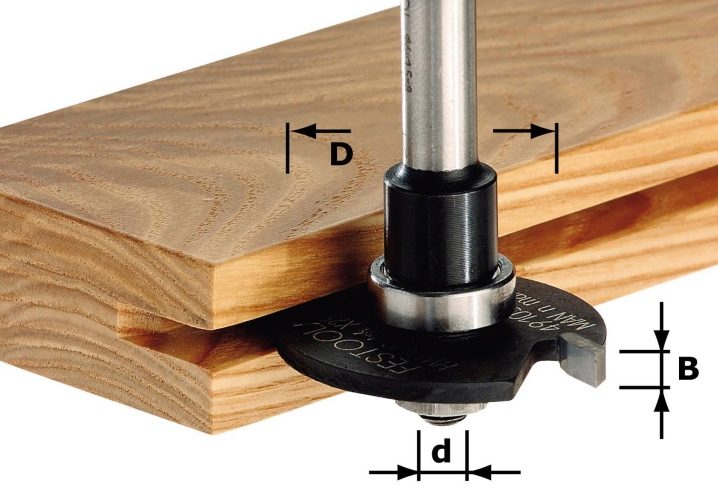

The lining is a special board with a groove on one side and a tongue on the other. Therefore, you will need two types of cutters, the function of each of them will be designed specifically for processing the board from one side. The difference between cutters can be the diameter of the shank, the size of which determines the power required for their application.

Each disc milling cutter has a standard design, it consists of:

- the basis of the nozzle is the axis on which the entire main part is fixed;

- on top of the axis two discs are attached, on which the cutting knives are located;

- there is a bearing in the discs.

The cutting teeth of the nozzle can be independently sharpened 3-4 times for reuse.

Milling machine

This is a machine with interchangeable attachments. The router is mainly used for processing wood products, but with the purchase of additional equipment, it can also process both plastic and metal. Such a machine has a rather small size for its functionality, it can be used for almost all purposes, from the manufacture of various parts to the processing of furniture and household products.

There are various types of milling tools:

- upper;

- edging;

- lamellar.

The use of such a device is very convenient and functional.

Independent production of lining

Step-by-step instructions for performing work.

- First you need to prepare or purchase flat boards of the size you need. It is better to choose the length of no more than two meters in order to work with the material more conveniently. The width must be chosen and calculated independently (usually it is done 8-10 cm). When trimming boards, the remaining material does not need to be thrown away; interconnecting strips can be made from them.

- Then you need to qualitatively process the board, preparing it for work.

- After the board has been completely processed, you can start cutting the tongue and groove. During this work, it is necessary to do everything clearly and measuredly, since the likelihood of doing something wrong at this stage is quite high. The board must be well and tightly fixed, the table on which the work will take place must be in a stable position. The depth of the groove and the width of the tongue must be constantly adjusted, since even with minimal displacement the board will be damaged.

- In some cases, it will not be possible to get by with a manual cutter, since in the production of, for example, a calibrated board, more complex equipment will be needed - a thickness gauge.

Throughout the entire time of work, all safety measures must be observed, protective goggles and gloves must be used, since various types of injuries can be obtained at all stages of processing.

Choosing cutters for wood

When choosing cutters, you need to take into account all their features, firstly, it is desirable that the cutters are made of high quality, the quality guarantee in most cases is the brand, therefore it is best to buy tools that have already been tested by time, such brands include tools from the firm "Shtil". Secondly, it is necessary to be guided by the strength of the material from which the cutter is made, it must be selected based on what material this tool will need to work with. And, thirdly, it is necessary to choose the right type and type of tool that will suit your type of work, for example, as mentioned above - a disk cutter is more suitable for working with clapboard.

Conclusion

Summing up, we can say that a person who is used to doing work with his own hands should have a set of all types of cutters for working with various materials and various details.

In our case, it can be noted that when performing facing work, all types of cutters are suitable, but for working with lining, it is preferable to use disc cutters, which are of different types, each of these types is necessary at different stages of work.

After all the work, you will receive not only a beautiful interior view of your home and a storm of positive emotions, but also considerable savings, because buying ready-made facing boards will have to spend almost twice as much as buying a set of all the necessary tools and making the lining yourself.

For information on how to choose cutters for lining, see the next video.

The comment was sent successfully.