Thermal conductivity of mineral wool

Mineral wool is a general term for inorganic insulation, which is made from rocks, blast furnace slag and glass. Today mineral wool is in demand, it is widely used in construction. This insulation gained popularity due to its thermal conductivity and acceptable cost.

What it is?

Mineral wool consists of thin fibers pressed into a mat. Outwardly, it is similar to medical cotton wool, only more rigid. Minvata is recognized by specialists as one of the best heat-insulating materials, since it has the following advantages:

-

efficiency,

-

safety for human health,

-

ease of installation,

-

affordable cost.

There are 3 types of mineral wool.

-

Stone - is made from molten rocks. Dolomite, basalt and limestone are mainly used for its creation. Such insulation is reliable and durable, has a long service life.

-

Slag - is made from molten blast-furnace slag. When creating, waste of ferrous and non-ferrous metals is used. This insulation is less durable, inferior in quality to stone wool - it should not be used in climatic zones with high humidity levels and sudden temperature changes.

-

Glass (fiberglass) - is obtained from molten fiberglass, as well as from sand, soda, limestone, dolomite, borax. The main characteristics are high density, elasticity and shape memory. It has good indicators of thermal conductivity and vapor permeability, but the characteristics are inferior in quality to stone (basalt) and slag wool. Popular due to the ratio of quality and affordable cost.

Despite the different raw materials, all varieties of mineral wool have a common property - the material is loose, with a fibrous structure and low density, and for this reason has a low thermal conductivity.

The thermal conductivity of mineral wool is influenced by the mineralogical composition, density and humidity. The average indicator for different types of mineral wool is usually 115 kg per 1 cubic meter. m with water absorption no more than 1% by volume. The average fiber diameter is no more than 0.2 microns.

Coefficient of thermal conductivity

Thermal conductivity of materials is the ability to store thermal energy in a room, one of the important parameters of thermal insulation materials. The area of their use depends on the characteristics of heat insulators.

The coefficient reflects the amount of heat that is carried out in 1 hour after 1 sq. m of the surface of the insulation with a thickness of 1 m, the absence of heat leaks on the sides and a temperature difference of 1 ° C for both surfaces are also taken into account. That is, the low thermal conductivity parameter of mineral wool indicates a minimum heat loss.

The coefficient is measured in W / (m ° C), initially depends on the feedstock, which affects the structure of the fiber. The indicator does not remain constantly at the same level - for example, in 3 years it can increase by 50% due to the ingress of moisture into the structure. The parameter is used in calculating the required thickness of the thermal insulation layer for interior or exterior decoration. The lower the indicator, the thinner the layer will be needed to insulate the building structure (roof, walls, floors, etc.) and, accordingly, the lower the costs.

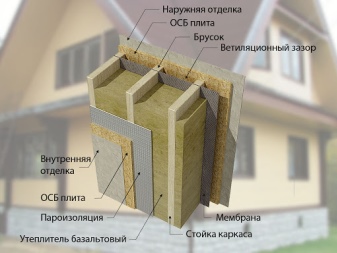

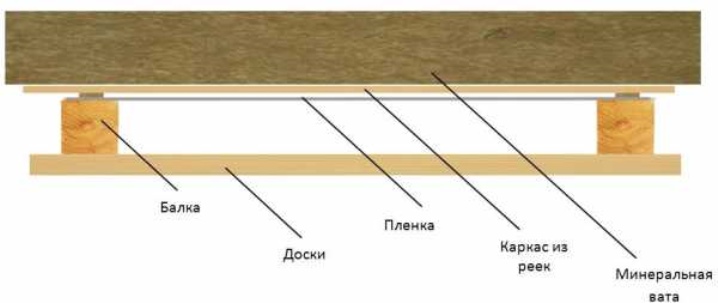

Increasing or decreasing the layer thickness will not affect the coefficient in any way.Only the selected raw materials affect the value of thermal conductivity, but the thickness of the insulation is important for protecting structures. For example, mineral wool up to 50 mm thick is often used for internal insulation of premises (floors, partitions, interfloor ceilings, etc.), where heat losses are small and space is required to be saved. For external insulation (facades of houses, roofs), mineral wool with a layer thickness of 100-200 mm is used.

The thermal conductivity coefficients, taking into account the feedstock, are:

-

stone (basalt) wool - 0.032-0.046 W / (m ° C);

-

slag wool - 0.46-0.48 W / (m ° C);

-

fiberglass wool - 0.038-0.046 W / (m ° C).

The main disadvantage of mineral wool is the change in the level of thermal conductivity when moisture enters the material. Thus, an increase in humidity by 5% worsens the thermal insulation properties by almost 50%. And moisture that gets inside during freezing can deform the insulation and disrupt the operational properties.

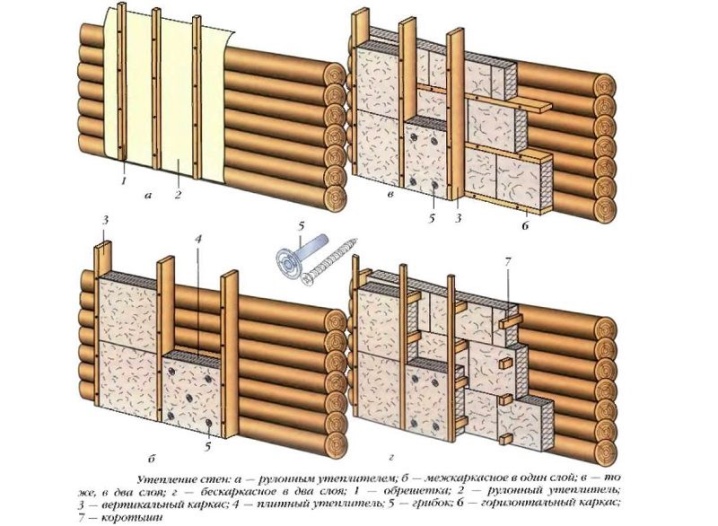

Stone wool, for example, from basalt, is least susceptible to changes in thermal conductivity. Due to the high level of vapor permeability (water absorption - less than 1%) and minimal hygroscopicity, excess moisture evaporates, and does not accumulate inside the product. For this reason, stone wool is often used for external insulation (facades, roofs of buildings), and for thermal insulation of the floors of the first floors in order to reduce heat loss.

Fiberglass and slag wool is not suitable for outdoor insulation and for use in rooms with high humidity. This is due to an increase in thermal conductivity with increasing humidity levels. So, when installing these types of mineral wool, complete insulation from moisture is required.

Comparison with other heaters

Each insulation has thermal conductivity, and it is this ability that determines the quality of the product and the scope of its application. The average values of mineral wool are 0.045 W / (m ° C), and such a low value confirms the high quality of the heat insulator.

If we compare the average coefficients of thermal conductivity of various heat insulators, we will see illustrative examples of the layer thickness required to retain heat:

-

brick 1460 mm - 0.520 W / (m ° C);

-

expanded clay 869 mm - 0.170 W / (m ° C);

-

fiberglass wool 189 mm - 0.044 W / (m ° C);

-

stone (basalt) wool 167 mm - 0.039 W / (m ° C);

-

expanded polystyrene 159 mm - 0.037 W / (m ° C).

When comparing mineral wool with other heaters, you can evaluate both its advantages and disadvantages.

-

Expanded polystyrene... No less popular insulation (a type of foam). The thermal conductivity value is 0.028-0.035 W / (m ° C). If we compare the heat-conducting qualities with mineral wool, then its energy-intensive properties will be less effective. Nevertheless, mineral wool wins significantly when comparing the fire resistance and harmfulness of insulation fumes. The ease of installation and the cost of this type of heat insulator are not inferior to mineral wool.

-

Penoplex... It is also a type of foam, but these are more modernized products. Thermal insulation characteristics are better than that of mineral wool - 0.03-0.032 W / (m ° C). The material is quite hard, it is not threatened with rotting, drying out and crumbling. These qualities are similar to mineral wool. Ease of installation and durability are also close to mineral wool. But the advantage of mineral wool is its resistance to fire, since its melting point is more than 1000 ° C, and penoplex is considered a fire hazardous material.

-

Expanded clay... The value of thermal conductivity is about 0.09 W / (m ° C), worse than the indicator of mineral wool, but the main advantage of this heat insulator is its high safety and environmental friendliness. Due to the high thermal conductivity, a greater layer thickness is required for insulating a room than, for example, stone wool. Products made of mineral wool are easier to install, but in terms of durability, mineral wool is still inferior to expanded clay.

- Wood sawdust. An excellent material for thermal insulation of premises, it has a thermal conductivity parameter of 0.06-0.08 W / (m ° C).The advantage of the insulation is its high vapor permeability, as well as resistance to condensation and moisture. The advantages also include environmental friendliness, low cost of material and safety for human health. But in installation, such a heat insulator is more complicated, and for high-quality insulation it is required to form a layer from a raw mixture, for example, sawdust and clay or cement. Pure sawdust is practically not used due to the fire hazard. The service life of mineral wool and sawdust with additives is practically the same.

The thermal conductivity of mineral wool is one of the parameters, the correct use of which will allow you to select the required layer thickness for thermal insulation.

To create an optimal comfortable microclimate in rooms made of wood, brick, gas blocks and other building materials, the correct selection of heat insulators will help: use stone wool for external insulation, and slag or glass wool for internal insulation. This approach will help increase the life of the materials.

The comment was sent successfully.