Mineral wool sandwich panels

When erecting various buildings, including residential ones, it is imperative that there is a need to create an insulating coating. For these purposes, a variety of building materials are used. Sandwich panels made of mineral wool are very popular. Today we will talk about the main advantages and disadvantages of such a material, as well as what characteristics it has.

Peculiarities

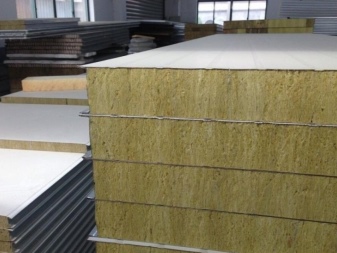

Mineral wool is a dense building material that consists of many interconnected fibers. They can be arranged in a chaotic manner, or be arranged horizontally or vertically. Also, sometimes models of spatial and corrugated views are distinguished separately.

Panels made from such material are quite flexible, so they can be used for mounting on surfaces of a wide variety of geometric shapes.

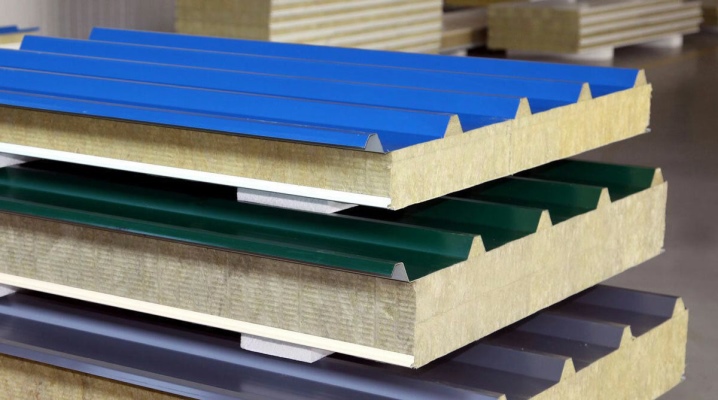

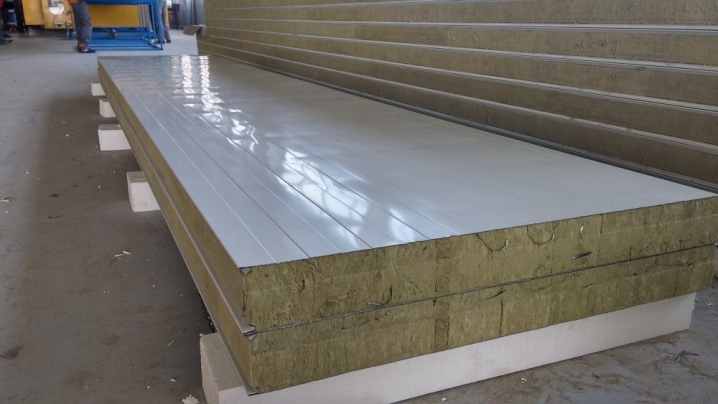

Sandwich panels are two connected steel elements, between which mineral wool is placed. They are parallel to each other and securely fastened. As a rule, basalt-based materials are taken for the production of these building panels.

The basalt part can be additionally treated with a special impregnation, which makes it possible to increase the water-repellent properties of the material and extend its service life.

Steel parts can easily withstand various adverse influences, so they can be used in rooms with increased sanitary requirements. Food grade or non-food grade steel can be used. In any case, the metal is coated with protective substances in several layers, which increases the resistance to corrosion. The metal part and the insulation are fixed to each other using a special adhesive made on the basis of polyurethane.

The front surface of structures is most often coated with a special polymer with a coloring pigment. Such a decorative layer easily tolerates temperature extremes, exposure to ultraviolet radiation, while it can retain its original appearance for a long time.

Advantages and disadvantages

Mineral wool sandwich panels boast many significant benefits. Let's highlight some of them separately.

- High level of quality. These designs will provide excellent thermal insulation for many years.

- Low weight. This advantage greatly facilitates the installation and transportation process.

- Stability. Mineral wool is not afraid of the negative effects of low and high temperatures and moisture.

- Fire resistance. This material is completely safe. It is non-flammable and does not support combustion well.

- Mechanical strength. Sandwich panels are particularly hard, which is achieved due to the vertical arrangement of the fibers. During operation, they will not break and deform.

- Environmental friendliness. Mineral wool will not harm human health. It will not release harmful substances into the environment.

- Vapor tightness. This insulation material is created in such a way that moisture does not penetrate into the room, and the excess amount of steam does not return in the opposite direction.

- Noise isolation. Mineral wool structures can be used not only to provide thermal insulation, but also to organize sound insulation. They perfectly absorb street noise.

- Simple installation technology. Anyone can install such panels, without the need to turn to professionals for help.

- Affordable cost. Sandwich panels have a relatively low price, they will be affordable for almost all consumers.

- Resistance to biological adverse effects. Over time, mold and mildew will not form on the surface of this material.

This material has practically no drawbacks. It should only be noted that when exposed to a large amount of moisture, such panels will get very wet and begin to lose their thermal insulation properties, so you should not allow the structure to come into contact with moisture.

Main characteristics

Sandwich panels made of mineral wool have a number of the most important parameters.

- Density ranges from 105 to 130 kilograms per m3.

- Thickness can vary significantly depending on the specific purpose, more often models with values of 100, 120, 150, 200 mm are used. It is these samples that are taken for the insulation of wall coverings.

- The weight of these sandwich panels can also vary greatly. It will largely depend on the dimensions of the products. On average, such insulating fillers can weigh 44.5 kilograms per square meter.

- The length of rockwool sandwich panels differs depending on what construction they will be used for. So, roofing and wall samples often have a length of 2,000 to 13,500 millimeters.

It should be noted that all these products, made of mineral wool, have excellent fire resistance, low thermal conductivity, incombustibility, and good rigidity. The additional hardness of the material is achieved through correct installation.

Applications

These sandwich panels are widely used in various fields, but their main purpose is to provide thermal insulation. Moreover, they can be used not only for wall, but also for roofing structures when building a house.

Also, mineral wool will be an excellent option for insulating doorways. It is often used in the process of installing windows in a home.

These panels will be perfect for structures that have special fire safety requirements. They are often purchased for external ventilated facades, when creating internal partitions. Sandwich panels are often used in the arrangement of cultural, entertainment and sports complexes.

The comment was sent successfully.