Features of mineral wool cylinders

To reduce the loss of thermal energy, mineral wool was previously used. This material has been widely adopted due to its affordable price and optimum performance. Advances in technology have led to the creation of more versatile and durable materials with which you can store heat. Cotton wool was replaced by special cylinders.

Compared to the previous version, they cope better with the task at hand. Also, manufacturers have managed to increase their service life through the use of innovative materials. Nowadays, mineral wool cylinders are actively used in various fields.

Advantages and disadvantages

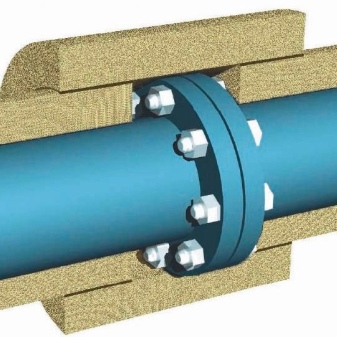

Mineral wool cylinders are a separate type of thermal insulation product. Their main purpose is pipe insulation.... In production, raw materials of inorganic origin are used, which are obtained by smelting siege or rock. Also included are slag of volcanic origin, various industrial waste, including metallurgy.

Insulation of a cylindrical shape is produced taking into account the GOST or TU standards. If the manufacturing process is disrupted or poor quality materials were used, the product will not cope with the task.

The new insulation has become widespread due to its many advantages.

- The first and main plus is low thermal conductivity. The material retains heat while maintaining the required temperature. This characteristic is due to a special structure.

- The main material (mineral wool) is not afraid of fire. Trade marks have taken care that the manufactured product is not prone to fire. Even under prolonged exposure to high temperatures, the cylinders retain their shape.

- Quality material has a long service life. Regardless of which composition was chosen for the product, it can last for several decades. Even options from the budget price category retain their commercial qualities for 50-60 years.

- The cylinders cope remarkably well with intense and prolonged loads. Cotton wool fibers are tightly intertwined, keeping their shape even under high pressure.

- Modern insulation is not afraid of moisture. The surface of the insulation is covered with dense foil or a special fabric that prevents water from getting inside.

Even the highest quality and most widespread thermal insulation material has its drawbacks that must be considered before using it:

- insufficiently high waterproofing;

- after installation, the insulation layer cannot be controlled;

- the use of cylinders is a labor-intensive process when insulating pipes.

Note: the list of disadvantages can be increased if a poor quality product falls into the hands of the buyer. Also, disadvantages may be associated with a violation of the styling process.

How are cylinders made?

For the manufacture of cylindrical heat-insulating material, minerals of mountain origin (basalt materials) are used. All components in the insulation are monitored for radiation levels. This indicator must necessarily comply with the established international standards.

All responsible and reliable manufacturers have appropriate certificates that confirm the safety of the raw materials used.If you doubt the quality of the purchased product, be sure to ask for these documents when purchasing insulation.

The first stage of production consists in cutting stone wool into layers, then each sheet is processed using special binders. After thorough impregnation, the sheets are passed through special equipment that compacts the material. The result is thermal insulation in the form of a cylinder or a half-cylinder.

Next stage - product drying... This process continues until the special impregnation has completely hardened. In some cases, production includes additional steps. They are necessary in the manufacture of reinforced or laminated insulation.

The development of technology makes it possible to fully automate the production process. All stages, from cutting cotton wool into separate layers to drying, are performed practically without human intervention. The innovative equipment produces a high quality product, producing large batches of thermal insulation.

Note: Cylinders can be of different sizes. Typically, the standard length is 1200 millimeters. The minimum diameter is about 18 millimeters, and the maximum is more than 300 millimeters.

Applications

Mineral wool cylinders are actively used at the present time. Their main purpose is pipeline insulation.... The diameter of the pipes can be different and vary from 18 to 1420 millimeters. Also, trademarks suggest using this material in a temperature range from 1800 degrees Celsius below zero to 7000 Celsius with a plus sign.

This version of thermal insulation products has found its application when working with the following types of structures:

- heating network;

- oil and gas pipelines;

- hot and cold water supply;

- technical pipelines (high fire safety requirements are imposed on structures of this type);

- valves and fittings.

Note: if cylinders are used to insulate small pipes, it is enough to lay them in one layer.

Also, mineral wool insulation can cope with the following tasks:

- the product can be used to protect pipes from the damaging effects of ultraviolet rays;

- they can be used to increase the strength of main pipes;

- the material demonstrates high sound insulation - if the pipes through which water flows are covered with insulation, its noise will not be heard;

- some use a mineral wool product as a protective layer, it will protect the structure from destructive external influences.

Description of species

Glass wool

It is the most common type of material based on glass fibers. When working with this product, it is imperative to protect yourself with protective clothing. Contact with fine fibers can cause serious harm not only to the skin, but also to health.

Slag

The second option, which has found application as an effective heat insulator. Its significant drawback is that when it comes into contact with metal, the material enters into an acidic reaction. The product absorbs moisture, as a result of which the thermal insulation properties are significantly reduced. As in the first case, protective equipment is required for laying slag wool.

Stone wool

The last mineral wool product for the manufacture of which the following components are used - diabase and gabbro. In terms of its operational properties, it is very similar to slag wool. However, this product does not absorb moisture. Also, the sheathing does not prick.

Note: the modern assortment offers a variety of insulation, differing in a set of technical and operational characteristics. The product on synthetic binder fiber can be produced in a galvanized or foil-coated sheath. Manufacturers also use the term "shell".

Cylinders lined with aluminum foil have become the most widespread due to their practicality. A thin layer of metal protects the cotton wool from moisture, sunlight and other damaging effects.

Dimensions (edit)

To meet the needs of discerning buyers, brands offer a variety of sizes. This parameter means the diameter of the cylindrical insulation. The minimum diameter indicator is 1.8 centimeters. The highest value is 16 centimeters. The width of this product may also vary. The maximum indicator reaches 102 centimeters.

The demand for this type of insulation is constantly growing, and therefore brands are expanding the dimensional grid, offering new options. In some cases, manufacturers can customize cylinders to customer specifications. This option is better suited for special designs.... However, made-to-order products are much more expensive than finished products.

Nuances of choice

Before making a purchase, you need to decide on the following factors:

- the diameter of the pipes for which a cylindrical insulation is chosen;

- the place where the insulation will be carried out (open area or closed room);

- indoor humidity and temperature indicator;

- the maximum temperature that the thermal insulation product will withstand;

- other operating conditions.

Be sure to check the quality with certificates. The presence of the relevant documentation confirms that the product is safe for health and the environment. The papers also indicate that the mineral wool cylinders were manufactured in accordance with GOST standards.

Usage Tips

The use of insulation prevents heat loss from the pipe surface. To make the most of the capabilities of this product, it is necessary to correctly install it. This process should be carried out by a professional who knows all the intricacies of laying and subsequent dismantling of the material. The cylinders must fit tightly to the pipes and be securely connected to each other.

Any type of transport can be used to transport mineral wool cylinders. To protect the product during transport, manufacturers pack it in heavy cardboard boxes.

It is best to store the material in a covered area. You can also leave the insulation under the shed for a short period of time. The main thing is that direct sunlight and atmospheric precipitation do not fall on the insulation.

The comment was sent successfully.