Mineral wool adhesive

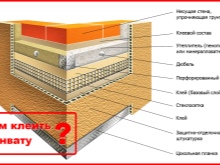

Mineral wool is used in construction as insulation. The efficiency of heat preservation depends on the technology of its installation, which is not limited to fastening the insulation to the surface with fasteners - dowels. Installation according to the rules consists in the preliminary application of glue to each sheet of mineral wool.

Characteristic

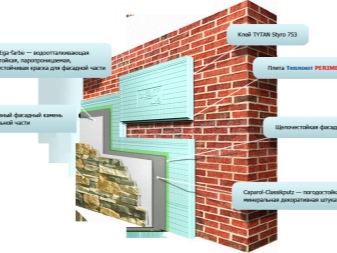

Insulation of the building facade is a frequently used option in construction. As a rule, a material based on mineral wool is used, which is practical and not very expensive. When choosing an adhesive for fixing mineral wool insulation, one should be guided by the fact that all operations will be carried out outside. When purchasing glue, you should carefully read the manufacturer's recommendations and instructions.

The compositions of adhesive masses for different types of mineral wool-based insulation may differ, but they all correspond to certain characteristics.

- The adhesive layer applied to the surface of the insulation must remain flexible, which will reduce the likelihood of defects in the adhesive seam in the form of cracks. Responsible for this is the quality of the plasticizers and modifiers that make up the glue for mineral insulation.

- The adhesive must have a high adhesion coefficient.

- The glue should not interfere with air exchange. Otherwise, condensation will accumulate in the internal space between the wall and the insulation, which will disturb the indoor microclimate.

- The mixture prepared for work must have a long working life. This is necessary in order to provide a sufficiently voluminous front of work, without being distracted by the preparation of new portions of glue.

- The adhesive mixture must be resistant to low temperatures, since it is applied outside the building. All processes associated with freezing and thawing must proceed without violating the integrity of the adhesive seams.

- The thickness of the adhesive layer should not affect the quality of the fastening.

- The adhesive must have an optimal drying speed.

- The glue for mineral wool insulation, which is necessary for fixing them on vertical and horizontal planes, must ensure tight contact of the wall, foundation or floor with the thermal insulation kit.

The adhesive mixture, selected with a deviation from the above conditions, will not be entirely effective.

Types of compositions

There are all-purpose adhesives, but they are of limited use. Working with such tools is complicated by their averaged indicators. There are three main types of adhesives in construction.

Dry glue, packaged in bags. It is a dry adhesive mixture consisting of cement, sand, synthetic resin, and a small percentage of additives. Manufacturers use thick paper bags as containers for glue. The weight of one bag is from 5 kg to 25 kg.

When starting to lay the insulation, the dry product is transferred into a solution. To prepare the solution, use only clean water. The amount of water for each brand of glue is determined by the instructions.

It is recommended to use a construction mixer to obtain a high-quality homogeneous mixture for mixing. The work uses a mass that has a thick consistency. A solution prepared from a dry product hardens quickly. Therefore, you should knead in small portions, which must be used within one hour.

The addition of water to the frozen solution will not be able to return the mass to its working parameters.

Ready-to-use composition, packaged in a container. The manufacturer supplies containers with glue of various volumes to the construction market. The container is a plastic bucket equipped with handles and a lid. This allows you to schedule work for a different number of people. For one person, glue is used in a smaller container.

The finished solution, as well as prepared from a dry product, quickly solidifies, turning into a solid mass. Therefore, it must be consumed quickly, it is not possible to re-dissolve and transfer the mixture to a working state.

Polyurethane adhesives. This type of glue is a foam based on urethane resins. Such glue goes on sale in special packaging - cylinders. The cylinders can be equipped with a dispenser or an additional glue gun must be purchased. The property of glue-foam is a high degree of adhesion, regardless of the type of base and the insulation mounted on it.

This adhesive has the following advantages:

- direct use without special preparatory operations;

- reducing the time for applying the adhesive;

- it is possible to work with glue based on polyurethane in any region, in any weather conditions (in rainy and hot weather);

- high moisture resistance and vapor permeability represent additional advantages of the application;

- there are no harmful components in the glue, their release during operation is not observed;

- bonded surfaces have a long service life.

The consistency of the glue-foam is almost the same as the consistency of polyurethane-based polyurethane foam.

The cost of foam glue is higher than that of other adhesives used for installing insulation, but in addition to the listed advantages, this tool is characterized by a higher adhesion to surfaces.

Product overview

Among the total mass of adhesive mixtures for insulating buildings, there are products that are popular and in great demand. On the advice of those who used adhesives for insulating facades, many users purchase the following tools for installing insulation.

- EK Thermex, plaster and glue mix. It is a product ready for gluing insulation. In accordance with the instructions, add water to the mixture selected for work, mix until a homogeneous consistency and apply the solution to the surface. The bonded surfaces after the glue dries are firmly bound and do not require the use of additional fasteners. The mixture of this brand can be used on brick, ceramic, porcelain stoneware surfaces. The main components of the plaster-adhesive mixture:

- astringent component - cement;

- free-flowing fine component - sand with a particle size of 0.1 to 5 mm;

- polymer modifying components;

- special additives for uniform sand distribution.

The modifier in the adhesive composition serves to increase the resistance of the adhesive to low temperatures, increase the adhesion parameter, increase the plasticity of the adhesive, and the ability to slow down or increase its drying rate.

Possible additions of gypsum, bitumen, surfactants and other compounds.

- Ceresit CT 180. It is a dry mixture, the composition of which is designed for fixing mineral wool-based insulation to the external vertical and horizontal planes of buildings. The Ceresit 180 mixture is characterized by the most durable connection between the mineral wool slab and the surface of the facade of the house. At the same time, the ideal preservation of the heat-insulating functions is ensured. The advantages of the mixture are as follows:

- can work in the range of external temperatures from -50 ° C to + 70 ° C;

- high parameters of adhesion of the surface of walls and insulation based on mineral wool;

- a layer of Ceresit 180 glue, which holds the insulation to the surface, has a high vapor permeability, it transmits well not only air, but also steam;

- glue is applied in a very thin layer on a pre-leveled surface, and at low consumption, the adhesion of the surfaces is not reduced.

The manufacturer supplies the construction market with Ceresit 180 adhesive mass in 25 kg paper bags. For 1 sq. meter consumes about 6 kg of the mixture.

- Ceresit 190 glue. Manufacturers offer users two options for glue: summer, using at temperatures from + 5 ° C to + 30 ° C, and winter, using at temperatures from 0 ° C to + 15 ° C. The dry mix goes on sale in paper bags. Each package weighs 25 kg. The main application of the Ceresit CT 190 building mixture is the installation of insulation boards on the outside of the building.

Choice

Adhesive for insulation such as mineral wool can be of different types: universal or specialized. If a mineral insulation made of glass wool or basalt is used for the facade, then you can choose a specialized glue for fixing it.

Universal glue is suitable for working with heaters made of other materials, for example, for expanded polystyrene, expanded polystyrene, polystyrene foam. This glue can be used when fixing a reinforcing mesh on walls with glued insulation mats of any kind.

Wooden buildings, as a rule, do not require additional wall insulation. Mineral wool insulation is attached to roof and floor ceilings of wooden houses using fasteners such as nails and dowels.

Application technology

The process of fixing the insulation will consist of a number of steps:

- a glue solution is prepared according to the attached instructions;

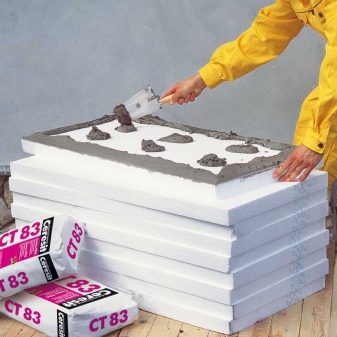

- to attach the insulation, it is necessary to distribute the glue over the entire surface of the mat, paying attention to the perimeter and center, and a notched trowel is used as a tool;

- first, you need to attach one sheet of insulation to the wall, then fill the first row to the end, after which each mat is carefully pressed against the wall;

- the second row of mineral wool slabs is fixed with an offset, by analogy with brickwork;

- insulation mats along the openings of doors and windows, in the corners of the room are cut strictly along the contour of the openings and according to the measurements of the angles;

- you should pay attention to the fact that in the corner of the insulation slabs go over each other in a checkerboard pattern;

- in the corner, the joints of the insulation plates are fastened with dowels in the corners and in the center;

- with the help of glue, the insulation is reinforced with a special mesh made of fiberglass.

When performing the front version of insulation, you should first measure the area on which the insulation mats will be placed, and calculate the forthcoming consumption of glue. Finishing the process of warming is finishing the facade with decorative plaster.

The video below will tell you about glue for mineral wool.

The comment was sent successfully.