Izovol: features and types of products

Every person wants to be warm and comfortable in his home. The optimal atmosphere can be achieved by insulating the walls, floor and ceiling. In this way, uniform circulation of heat in the room is achieved, thanks to which you can significantly save on heating. One of the modern high-quality insulation materials is Izovol - environmentally friendly mineral wool produced in Belarus. You will learn about the features and types of such products by reading this article.

Properties

Izovol is recognized as the latest generation of insulation. The manufacturing plant located in Belarus produces a wide range of mineral wool. Rocks of gabbro-basalt and its analogues are used as raw materials.formed as a result of volcanic lava eruptions. A special approach in production allows you to reduce the cost of it and the cost of insulation.

The material is characterized by a fibrous structure, saturated with air. Due to the large amount of air in the composition of the product, the insulation has almost zero thermal conductivity.

The environmental friendliness of the material is confirmed by quality certificates from Belarus, Russia and Europe. The production completely excludes the use of coke and blast-furnace slag. The use of only natural ingredients made it possible to achieve such high performance qualities that Izovol products have.

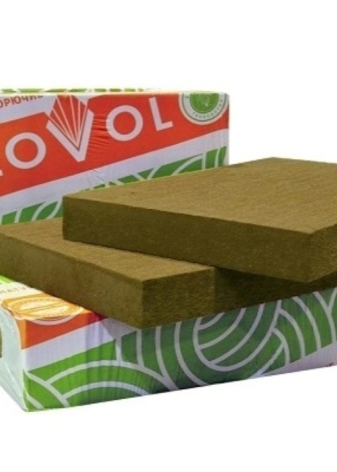

Raw materials are presented in the form of slabs, rolls and mats, and all have their own characteristics. Mineral wool can be soft, hard or semi-rigid to the touch, depending on the series. Moreover, each of the species is a dry material, which is especially valuable.

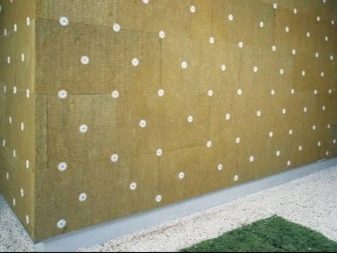

Insulation Izovol is a modern building material and is widely used in the construction industry for cladding interior and exterior walls. It is suitable for use in flammable buildings (baths, saunas).

Today, such products are not very well known to Russian consumers, but those of them who have already tried the material leave only positive reviews.

The company entered the market 10 years ago. The manufacturer claims that the insulation is able to maintain its qualities from 50 to 80 years.

Material advantages:

- environmentally friendly raw materials are used for production;

- Izovol products do not emit toxic substances and are approved by the Ministry of Health of the Russian Federation;

- it is resistant to fire: does not ignite, but melts at a temperature of 1200 ° C;

- high level of noise and sound insulation;

- excellent vapor permeability;

- practically zero hygroscopicity;

- resistance to chemical, alkaline agents, alcohol compounds, essential oils;

- corrosion resistance;

- does not attract the attention of rodents and insects;

- not subject to decay and mold;

- tolerates stress well;

- significant service life;

- wide assortment (mats, plates, rolls, casings);

- ease of installation.

The material has a high level of elasticity, which makes it quite easy to work even with hard-to-reach areas.

Izovol mineral wool is hypoallergenic and does not harm human and animal health.

Numerous laboratory tests have confirmed the high quality and excellent performance properties of the material.

A slab of Izovol mineral wool with a thickness of 10 cm and a density of 100 kg / m3 is equal to the masonry:

- from a rounded bar of 25 cm;

- building bricks 160 cm;

- concrete 50-75 cm;

- sand-lime brick 200 cm.

Views

All heaters of this manufacturer are divided into several groups, each of which has its own definition. The numbers in the marking indicate the density level of the mineral wool.

Isobel

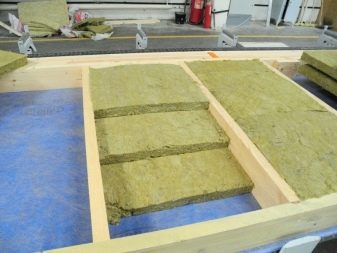

This option is universal and is suitable for thermal insulation in a private house, cottage, city apartment. Such materials can only be used for installation on the front of a building, roof, cold attic, as well as for floor insulation on logs.

Specifications:

- thermal conductivity - 0.036 W / mK;

- vapor permeability - 0.3 mg / mchPa;

- moisture absorption (with full immersion for a day) - 1.5% of the volume;

- density - 25 kg / m3;

- is completely non-flammable material.

"ST"

This type of basalt wool is widely used in the insulation of roofs and ventilated facades of buildings, attics, ceilings, floors and other wall structures. It is suitable for arranging thermal insulation of industrial equipment, ventilation systems.

Specifications:

- density - 50/60/90 kg / m3;

- thermal conductivity - 0.035 W / mK;

- steam conductivity - 0.3 mg / mchPa;

- is completely non-flammable material.

"K-120"

This material has a higher level of density (compared to previous varieties). It is advisable to use it for roof insulation. It is often placed as the first layer in a two-layer thermal insulation.

Specifications:

- thermal conductivity level - 0.035 W / mK;

- compression resistance - 35 kPa;

- the level of moisture absorption (with full immersion for a day) - 0.05%;

- is non-flammable material.

The material is made in the form of square slabs. Suitable for laying on horizontal surfaces.

"P-175"

This type is suitable for thermal insulation of floors under a concrete screed. This material can withstand heavy loads, it is resistant to compression.

Specifications:

- thermal conductivity level - 0.037 W;

- vapor permeability - 0.3 mg / mchPa;

- is non-flammable material;

- density - 175 kg / m3.

Thermal insulation for pipes

Izovol Mat - insulation for large diameter pipes. It can be used both for thermal insulation of pipes and for thermal insulation of industrial equipment, chimneys, air ducts.

Specifications:

- the density of the material can vary (40, 50, 60, 70.80 kg / m3);

- resistant to temperatures from -180 to + 570 ° C;

- thermal conductivity level - 0.034 W / mK.

Material sizes may vary.

"L-35"

This material is used for thermal insulation insulation, as well as for creating acoustic comfort in the room. It can be used to equip professional recording studios. In construction, it is popular for the insulation of the main types of structures, pitched roofs, frame walls, partitions.

It has the ability to drown out noise, while maintaining high thermal insulation values.

The density of the slabs is 35 kg / m3. Just like the previous types, it is a non-combustible material.

The Izovol product range includes other series (in addition to the above materials):

- Izovol "KV-150", "KV-175", "KV-200" - universal;

- Izovol "B-50" "B-75", "B-90" - for ventilated facades;

- Izovol "P-100", "P-175" - for thermal insulation of floors;

- Izovol "F-100" and "F-150" - for external walls.

High-quality mineral wool Izovol "Acoustic" is widely used as a sound-insulating material. It is suitable for installation on walls, floors, ceilings, elements of ventilation systems and air ducts. One package consists of 4 boards (total volume 0.24 m3).

When choosing mineral wool, it is important to pay attention not only to the type of insulation, but also to its series:

- SS and SC - designed for insulation of sandwich panels;

- L - lightweight material;

- NS - suitable for laying on the floor;

- F - designed for insulation of foundations.

Dimensions (edit)

Izovol mineral wool differs not only in characteristics, but also in the dimensions of the plates, sheet thickness:

- "Isobel" - 100x60 cm, thickness - 5, 7.5 and 10 cm;

- "ST-60" - 100x60 cm, thickness - from 4 to 25 cm;

- "K-100" - 120x100 cm, thickness - 6 cm;

- "P-175" - 100x60 cm, thickness - up to 10 cm;

- Mat - 100 cm, thickness - from 4 to 10 cm;

- "L-35" - 100x60, thickness - from 4 to 25 cm.

Helpful hints

The peculiarity of laying mineral wool is in its transportation, storage and correct installation.

By adhering to a few simple tips, you can avoid problems during the operation of the material:

- the transportation of mineral wool should be carried out in closed machines;

- you should carefully monitor the packaging, it should not be damaged;

- during transportation, slabs can be stacked in stacks no more than 2 meters high, and mats and rolls should be transported only in an upright position;

- the material should be stored in a dry and warm place, protected from precipitation;

- it is better to cut the rolls before unwinding, and it is better to cut the plates separately;

- when working with mineral wool, protective clothing, gloves, goggles and a protective mask should be used;

- to achieve the maximum effect, it is recommended to lay mineral wool around the entire perimeter of the building;

- when laying material indoors, it is recommended to ensure good ventilation;

- the thickness of the insulating layer for each region is selected individually;

- in some cases, it is necessary to lay the material together with a vapor barrier;

- after the end of the work, it is necessary to thoroughly wash your hands, face, change clothes and thoroughly clean the room.

Usually, in their reviews, consumers talk about the ease of use of Izovol mineral wool. Many people prefer it to other materials - due to its versatility, since you can choose insulation for heat, noise, sound, fire insulation. It is very popular with both construction professionals and amateurs. The ease of cutting and installation makes installation easy and affordable for almost everyone. Even without the necessary experience, you can easily cope with the installation of Izovol mineral wool.

However, Izovol products have several drawbacks. The high price of the material is not available to everyone, therefore, the choice is often made in favor of cheaper, but not such high-quality materials.

There are some inconveniences in the work. There are reviews about the difficulty of trimming material for insulating hard-to-reach places (for example, window slopes). However, specialists easily cope with such problems using professional equipment. The material is recognized as one of the best on the market - and for good reason.

Remarkable technical characteristics, performance, wide assortment, durability - this is why Izovol products are so fond of the majority of consumers from Russia and the CIS countries.

For more information on the use of Izovol, see the next video.

The comment was sent successfully.