Insulation Isover: an overview of heat and sound insulation materials

The building materials market abounds in a variety of insulation and soundproofing materials for buildings. As a rule, the main difference between them is the form of manufacture and the composition of the base, but the country of manufacture, the reputation of the manufacturer and the possibilities of application also play a significant role.

Heaters usually cost significant amounts, so in order not to be wasted, you need to rely on a guaranteed high-quality product, for example, products from Isover. According to experts and customer reviews, it occupies a leading position in such characteristics as service life, reliability and efficiency.

Peculiarities

Isover insulation is used both in residential buildings and in public institutions and industrial buildings. The production and sale of this product is handled by a company that is part of the international association Saint Gobain. - one of the leaders in the building materials market, which emerged more than 350 years ago. Saint Gobain is known for its innovative developments, the use of modern technologies and the high quality of its products. All of the above points also apply to Isover heaters, produced in different modifications.

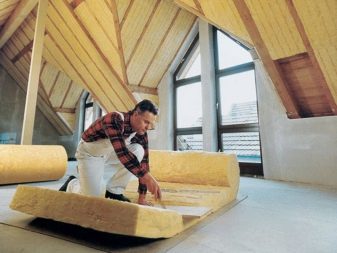

Isover products have a lot of the pros and cons of mineral wool, as they exhibit similar properties. On the market, they are sold in the format of plates, rigid and semi-rigid, and mats rolled into rolls according to our own technologies patented in 1981 and 1957. This insulation is used for the treatment of roofs, ceilings, facades, ceilings, floors and walls, as well as ventilation pipes. Isover is based on glass fibers. They are 100 to 150 microns long and 4 to 5 microns thick. This material is resilient and resistant to stress.

Isover insulators are tear-resistant, which means that they can be placed on structures of complex shapes. For example, these include pipes, elements of production lines, industrial equipment and others.

When using Isover as a heater or sound insulator, it must be protected from moisture.

Typically, vapor barrier and waterproofing films are used for this. It is customary to mount a vapor barrier from inside the house in order to protect it from condensation. The waterproofing film is placed outside, saving from rain and melting snow. As a rule, Isover is mounted without the use of fasteners, the only exception can be the insulation of the ceiling - in this case, dowels-"mushrooms" are used.

Under the "heading" of the brand, a lot of heaters are produced, which have different purposes and perform different functions. They are divided into two groups: for industrial and domestic use. In private housing construction, the material "Classic" is most often used, marked with the letter "K".

The price of Isover insulation may vary in different regions of our country. Typically, the average varies from 120 to 160 rubles per square meter. In some areas, it is more profitable to purchase it in packages, and somewhere - in cubic meters.

The subtleties of manufacturing

Saint Gobain has been operating in the Russian market for over 20 years and is engaged in the production of materials at two factories: in Yegoryevsk and Chelyabinsk. All enterprises undertake to undergo certification of the international standard of environmental management, which makes Isover insulation an environmentally friendly product that is on a par with cotton and linen in terms of its environmental characteristics.

The different types of Isover contain both glass and basalt fibers. This structure is the result of the processing of broken glass, quartz sand or mineral rocks of the basalt group.

- It is in Isover that minerals are used. Its constituents are melted and drawn into fibers following the TEL technology. As a result, very thin threads are obtained, which are interconnected using a special resin composition.

- A composition of cullet, limestone, quartz sand and other minerals is thoroughly mixed beforehand.

- To obtain a homogeneous flowing mass, the resulting mixture must be melted at a temperature of 1300 degrees.

- After that, the "liquid glass" falls on a rapidly moving bowl, in the walls of which holes are made. Thanks to physics, the mass flows out in the form of threads.

- In the next step, the fibers must be mixed with a yellow-tinged polymer adhesive. The resulting substance enters the furnace, where it is blown with hot air and moves between steel shafts.

- The glue is set, the layer is leveled and glass wool is formed. It remains only to send it under the circular saws to cut it into fragments of the required size.

When purchasing Isover, you can see the quality certificates. When the material is produced under license, the seller provides documents confirming the standards EN 13162 and ISO 9001. They become the guarantor that Isover is made of safe materials and there is no prohibition on its use indoors.

Varieties

There are different types of insulation, depending on whether they are sold in roll format or in slabs. Both varieties can have different sizes, and different thicknesses, and different laying technology.

Insulation materials are also subdivided depending on the industries of application. They are universal or suitable for specific areas - walls, roofs or saunas. Often the purpose of the insulation is encrypted in its name. In addition, it should be added that the materials are divided into those used indoors and on the facades of buildings.

It is also worth adding that Isover is classified according to the stiffness of the material. This parameter, related to the characteristics of GOST, is indicated on the package and is closely related to the density, the degree of compression in the package and the thermal insulation properties.

Advantages and disadvantages

All Isover heaters have similar positive and negative characteristics. If we talk about the pros, then the following are distinguished:

- The material has low thermal conductivity. This means that the heat "lingers" in the room for a long time, so it is possible to spend less money on heating, thereby saving significant amounts.

- The insulation demonstrates a high ability to absorb noise due to the presence of an air gap between the fibers, which absorbs vibrations. The room becomes as quiet as possible, protected from external noise.

- Isover has a high level of vapor permeability, that is, the material breathes. It does not retain moisture and the walls do not start to get damp. In addition, the dryness of the material increases its service life, because the presence of moisture negatively affects thermal conductivity.

- Heat insulators are completely non-flammable. On the scale of flammability, they received the highest rating, that is, the best resistance to fire. As a result, Isover can be used to construct wooden buildings.

- Slabs and mats are lightweight and can be used in buildings that cannot bear excessive stress.

- The service life can be up to 50 years.

- Insulation materials are treated with compounds that increase moisture resistance.

- The material is easy to transport and store. The manufacturer squeezes Isover 5-6 times during packaging, and then it completely returns to its shape.

- There are product lines with differing technical characteristics, designed for different areas of construction.

- Isover is highly resilient. The insulation surpasses other mineral wool in this indicator thanks to the special TEL technology, which is used for production.

- 5 centimeters of mineral wool is equal in thermal conductivity to 1 meter of brickwork.

- Isover is resistant to biological and chemical attack.

- Isover has a very affordable price, especially when compared to other alternatives.

- The material demonstrates high density and stiffness, which allows it to be mounted without additional fasteners.

However, there are still several drawbacks:

- A relatively complex installation process, during which it is necessary to additionally protect the respiratory system and eyes.

- The need to lay an additional layer of waterproofing during construction. Otherwise, it will absorb moisture, which will violate the thermal insulation characteristics. In winter, mineral wool can even freeze, which is why it is so important to leave a ventilation gap.

- Some types still belong not to non-flammable, but to self-extinguishing - in this case, you will additionally have to comply with fire safety requirements.

- The soft structure of the cotton wool limits the scope of application.

- The only disadvantage for industrial enterprises is that when the temperature rises to 260 degrees, Isover loses its properties. And it is there that such a temperature is quite possible.

Specifications

Isover is manufactured using a special patented TEL technology and has excellent technical characteristics.

- Coefficient of thermal conductivity very small - only 0.041 watts per meter / Kelvin. A big plus is the fact that its value does not increase over time. Insulation retains heat and traps air.

- With regard to sound insulation, the indicators for different models differ, but are always at a high level. This means that any kind of Isover will somehow protect the room from external noise. All this is ensured by the air gap between the glass fibers.

- With regard to flammabilitythen Isover varieties are either non-flammable or low flammability and self-extinguishing. This value is determined by the corresponding GOST and means that the use of almost any Isover is absolutely safe.

- Vapor tightness this insulation ranges from 0.50 to 0.55 mg / mchPa. When the insulation is moistened by at least 1%, the insulation will immediately deteriorate by as much as 10%. To prevent this from happening, it is necessary to leave a gap of at least 2 centimeters between the wall and the insulation for ventilation. The glass fibers will return moisture and thus maintain thermal insulation.

- Isover can serve up to 50 years and during a rather impressive period not to lose their thermal insulation qualities.

- In addition, the insulation contains components with water-repellent propertiesmaking it inaccessible to mold.

- It is also important that in fiberglass material bugs will not be able to settle and other pests. In addition, the density of Isover is approximately 13 kilograms per cubic meter.

- Isover considered environmentally friendly insulation and absolutely safe for human health.

- It is much lighter than the competition, therefore, it can be used in rooms made of fragile materials or in which it is prohibited to create unnecessary load. The thickness of a single-layer Isover can be either 5 or 10 centimeters, while for a two-layer, each layer is limited to 5 centimeters.Slabs are usually cut in meter by meter sizes, but there are exceptions. The area of one roll varies from 16 to 20 square meters. Its standard width is 1.2 meters, and its length can vary from 7 to 14 meters.

Recommendations for use

The Isover company produces not only universal insulation, but also of narrowly targeted actions, which are responsible for specific building elements. They differ in size, functions and technical properties.

Isover can be produced for light insulation (wall and roof insulation), general construction insulation (soft slabs for frame structures, medium-hard slabs, mats without fasteners and mats with foil on one side) and special purposes (for pitched roofs).

Isover has a special marking, where:

- KL are slabs;

- KT - mats;

- OL-E - mats of special rigidity.

The figures show the class of thermal conductivity.

The packaging also indicates where this or that type of insulation can be used.

- Isover Optimal It is considered a universal material that is used to process ceilings, walls, partitions, roofs and floors along the logs - that is, all parts of the house, except for the foundation. The material has low thermal conductivity and retains heat in the house, it is elastic and non-combustible. Installation is very easy, does not require additional fasteners, and, given its versatility, all of the above points make "Optimal" one of the most popular representatives of Isover.

- "Isover Profi" also a versatile insulation. It is sold as rolled mats and is used for roofs, walls, ceilings, ceilings and partitions. "Profi" has one of the lowest thermal conductivity and is very convenient to cut. The insulation can be 50, 100 and 150 mm thick. Just like "Optimal", "Profi" belongs to the NG class in terms of flammability - that is, it is absolutely safe in a fire situation.

- "Isover Classic" is chosen for thermal and sound insulation of almost all parts of the house, except for those that bear the greatest load. "Exceptions" include plinths and foundations. The material is sold both in rolls and slabs and has a low rigidity. The porous structure makes it an excellent insulator. However, this type does not differ in strength and durability, which means that it is not suitable for installation under a screed and for finishing walls under plaster. If, nevertheless, there is a desire to use it for facade insulation, then only in combination with siding, clapboard or facade panels fixed on the crate. "Classic" insulates the house very well and can reduce heating costs by almost half. In addition, it is a good sound insulator and protects the building from unnecessary noise.

- "Isover Warm House-Plate" and "Isover Warm House" used in the installation of most parts of the house. They have almost the same technical characteristics with the exception of volume and linear dimensions. However, it is customary to use slabs in one area, and mats in another. "Warm House-Plate" is chosen for insulation of vertical surfaces, inside and outside the house, as well as frame buildings. "Warm house", realized in the form of rolls of mats, is used to insulate interfloor ceilings and the floor above the basement (installation takes place between the logs).

- "Isover Extra" is made in the form of slabs with increased elasticity and 3D effect. The latter means that after squeezing, the material straightens and occupies all the free space between surfaces requiring insulation. Plates are tightly connected to each other and just as tightly adjoin surfaces. "Extra" is also versatile, but it is usually used for wall insulation inside premises. It should be added that it can be used for thermal insulation of facades in case of subsequent cladding with bricks, clapboard, siding or panels, and for roofs. Isover Extra is considered to be one of the most effective heat retention materials.

- "Isover P-34" is produced in the form of plates, the thickness of which can be 5 or 10 centimeters. They are mounted on a frame and are used to insulate the ventilated parts of the house - the facade or multilayer masonry. You can insulate both vertical and horizontal and inclined surfaces, since the model is very elastic. "P-34" is easily restored after deformations and is resistant to shrinkage. It is completely non-flammable.

- "Isover Frame P-37" It is used to insulate floors between floors, roof slopes and walls. It is important to take into account that the material must fit snugly to the surface. Isover KT37 also adheres tightly to the surface and is used to insulate floors, partitions, attics and roofs.

- "Isover KT40" refers to two-layer materials and is sold in the form of rolls. It is used exclusively on horizontal surfaces such as ceilings and floors. In case of insufficient cavity depth, the material is divided into two separate layers of 5 centimeters. The material has high vapor permeability and belongs to non-combustible materials. Unfortunately, it cannot be used on surfaces with difficult wet conditions.

- Isover Styrofoam 300A requires mandatory fasteners and is available in the form of plates. The material has increased moisture resistance and thermal insulation due to the presence of extruded polystyrene foam in the composition. This insulation is used to treat walls inside and outside the room, floor and flat roof. It is possible to apply plaster on top.

- Isover Ventiterm has a somewhat unusual scope. It is used for ventilated facades, pipes, plumbing, as well as for protecting precision instruments from the cold. You can work with it with or without fasteners. Such insulation is produced in the form of plates. Its technical characteristics are quite serious, especially in terms of strength - an order of magnitude better than that of ordinary mineral wool.

- "Isover Frame House" It is used to insulate walls from the outside and from the inside, pitched roofs and attics, as well as ceilings and partitions. In general, it is suitable for enhancing any frame structure in the house. The elasticity of the material helps to maintain its shape during operation and installation, and the stone wool fibers provide additional protection against noise.

Roofing

For roof insulation, some universal varieties of Isover are used, for example, "Optimal" and "Profi", as well as highly specialized - "Isover Warm roof" and "Isover Pitched roofs and attics"... Both materials are intended for the same purpose, but have different characteristics: they differ in the form of release, linear dimensions and the material used. They also undergo a special treatment that gives the products increased moisture resistance.

- "Warm roof" produced in the form of rolled mats. They are sold in plastic packaging with markings that allow you to cut the material to its width. "Pitched roofs" are realized in the form of plates, pressed and packed in polyethylene. They are used in the case of insulation of pitched and mansard roofs, as well as for surfaces inside and outside the building.

- "Isover Pitched Roof" used exclusively for roof insulation. It is moisture resistant, does not transmit sounds, has a high vapor permeability and is not flammable. As a rule, it is recommended to use it in two layers, and the upper one closes the joints of the lower one - this way the material will retain heat even better. "Pitched Roof" is produced in the form of slabs having a width of 61 centimeters and a thickness of 5 or 10 centimeters. Pitched Roof is highly hydrophobic - it does not absorb moisture, even if it is immersed in water for a long time. This allows the material to be used in difficult conditions that are not suitable for other insulation materials.

- "Isover Ruf N" is a heat insulation material for flat roofs.It has the highest level of thermal protection and is compatible with any building material.

- "Isover Master of Warm Roofs" also has a high thermal protection rate. Due to its vapor permeability, it excludes the accumulation of moisture in the wall. In addition, when insulated from the outside, the slab will retain its properties in any weather.

- "Isover OL-P" Is a special solution for flat roofs. It has ventilated grooves for moisture removal and is created using the “thorn-groove” technology, which increases the tightness of the mineral wool layer.

Facade under plaster

The following Isover varieties are used to insulate the facade for the purpose of further plastering: "Facade-Master", "Plaster Facade", "Facade" and "Facade-Light". All of them are realized in the form of slabs and are non-combustible material.

- "Facade-Master" pIt is used to insulate the facades of residential buildings up to 16 meters high. The plaster should be applied in a thin layer.

- "Plaster Facade", which is an innovative material, costs much less than the previous one, but performs the same functions and is applied under the same conditions.

- "Facade" used for subsequent coating with decorative plaster.

- "Facade-Light" used for houses with a small number of floors and for subsequent finishing with a thin layer of plaster. For example, this option is chosen by the owners of country houses. Such material is strong, stiff, but light in weight.

For soundproofing buildings

In order to protect the house from various noises, both external and internal, "Isover Quiet House" and "Isover Sound Protection" are used. Besides, you can also use universal heaters - "Classic" and "Profi".

- "Quiet House" has a high ability to absorb noise, therefore it is often chosen for soundproofing walls and partitions between rooms. Also, plates are used for horizontal surfaces - for logs, beams, spaces between the suspended ceiling and the original. The material has two functions, so the home becomes quiet and warm.

- "Zvukozashchita" possesses high elasticity, therefore it is often mounted inside the frame lathing, which acts as a partition or is fixed on the wall (in the case of facade coatings). The material can be used in combination with other insulation and thus create a double layer - keeping warm and soundproof. Such a solution will be especially effective for creating frame partitions and attic floors.

Insulation of walls inside

Isover Profi, Isover Classic Slab, Isover Warm Walls, Isover Heat and Quiet Wall and Isover Standard are recommended for thermal insulation and sound insulation of building walls inside and outside. These heaters are sold both in mats in rolls and in the form of saws.

- "Standard" usually chosen for insulating structures consisting of many layers. In this case, siding, lining, brick, block house and other materials can be used as finishing. In addition, these boards are suitable for thermal insulation of frame structures, for mansard and pitched roofs. Due to its medium density, the material is not suitable for further plastering walls. "Standard" has good elasticity, which means a snug fit to surfaces and structures. Plates are fixed using special clamping fasteners.

- "Warm walls" - These are slabs that are also made of glass fibers, but in addition are reinforced with a water-repellent treatment. This type is also used for thermal and sound insulation of walls inside and outside, installation in a frame, insulation of roofs, loggias and balconies. The increased moisture resistance becomes an additional plus in the last two examples. The material is resilient and elastic, does not slip or break.

- "Warmth and Quiet Wall" it is realized both in the form of slabs and rolls. The material has a porous structure, which allows it to perform two functions.In addition, this variety is characterized by increased vapor permeability and, as it were, "breathes". This allows you to create a comfortable environment in living quarters. Plates are elastic and they do not even need to be additionally fixed - they themselves qualitatively "creep" inside the frame.

- "Warmth and Quiet Wall Plus" has similar characteristics to "Heat and Quiet Wall", which will be discussed a little later, but has a lower thermal conductivity and better sound insulation. Slabs are used for walls inside a building, walls outside under siding or facade coverings and, if additional protection is available, for insulating frame structures.

Floor insulation

To insulate floors with high quality, you can choose two specialized materials - "Isover Floor" and "Isover Floating floor", which have slightly different technical and operational characteristics, which, however, combine damping properties and mechanical characteristics. Both types are easy to install, but using different technologies. In addition to insulation, these materials are also distinguished by high-quality double-sided sound insulation.

- Flor used for the construction of floating floors and structures on logs. In the first case, the material covers the entire surface and creates a warm and quiet floor. Due to its adaptation to high loads, the insulation can also be placed under the concrete screed.

- "Floating floor" always used to create a concrete screed that will not be connected to the walls and base, in other words, for a "floating" floor. Plates are always laid out on a perfectly flat surface and connected using a technique called "thorn-groove". Due to the fact that the fibers are arranged vertically, this type of insulation demonstrates outstanding strength characteristics.

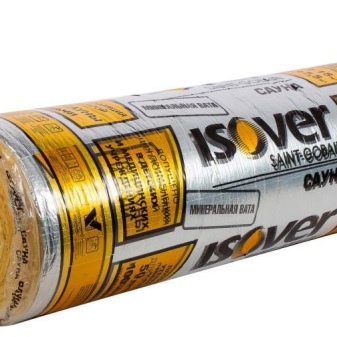

Bath thermal insulation

Isover has special solutions for thermal insulation of baths and saunas - rolled mats called "Isover Sauna". Such a coating has a foil layer on the outside, which reflects heat and creates a vapor barrier.

Sauna consists of two layers. The first is fiberglass based mineral wool and the second is foil. It should be noted that mineral wool is a non-flammable material, and the foil coating has a flammability class G1. It can withstand temperatures up to 100 degrees due to the presence of glue, and at a higher temperature it can ignite and extinguish on its own. To avoid an accident, the foil layer is additionally covered with clapboard.

Isover Sauna, on the one hand, performs the function of thermal insulation, and on the other hand, it acts as a barrier for steam, so that the mineral layer does not suffer from a large amount of vapors. The foil reflects heat away from the walls in the room and increases the level of heat retention.

Installation nuances

The first step is to choose the correct type of Isover, for this it will be enough just to look at the existing markings. Each product is assigned a class and number of stars, and this information is found on the packaging. The more stars, the better the heat-shielding properties of the material.

To insulate a house without special requirements, two stars are enough; for increased thermal protection and ease of installation, three stars are selected. Four stars have been assigned to the latest generation product with increased thermal protection. In addition, each package is labeled with precise information regarding thickness, length, width, package volume and number of pieces.

Mineral wool insulation is mounted in the same way as any other heat-insulating material. When insulating walls inside a room, the first step is to make a crate of wooden or metal strips. Drywall will be attached to them later. The walls are pre-grounded, and on those that border the street, a heat-reflecting coating is fixed.

When installing the battens, it is necessary to observe the step corresponding to the width of the Isover, slabs or mats.At the next stage, the sheets of insulation are glued to the wall, if necessary, a water-repellent film is fixed and horizontal strips are packed.

Insulation of walls outside the building begins with the fact that a wooden frame is attached to the wall.

- It is usually made from 50mm by 50mm bars that are attached vertically.

- The insulation can be mounted in one or two layers. It is placed in the structure so that it fits snugly against the wall and frame without gaps and crevices.

- Next, the bars are again attached on top, but already horizontally. The distance between the horizontal bars should be the same as between the vertical ones.

- With two-layer insulation, the second layer of thermal insulation is placed in the horizontal crate, and overlapping the joints of the first one.

- To protect against moisture, a hydro-windproof membrane is placed outside, the necessary ventilated gap is created, and then you can proceed to the cladding.

Insulation of the roof begins with the fact that a hydro-windproof membrane, which is also produced by Isover, is stretched along the upper edge of the rafters.

- It is fastened with a construction stapler, and the joints are glued with reinforced mounting tape.

- Further, it is recommended to start the installation of the roofing - a gap is formed over the membrane with the help of a pressure bar, and then the coating is installed on a counter-lattice of 50 by 50 millimeters of bars.

- The next step is to install a heat insulator directly. With a standard distance between the rafters, the insulation will need to be cut into 2 halves and each installed in the frame. Most often, one piece manages to insulate the entire length of the roof slope. If the distance between the rafters is non-standard, then the dimensions of the thermal insulation plates are determined independently. We must not forget that their width should be at least 1-2 centimeters more. The thermal insulation must fill the entire space without gaps or crevices.

- Next, a vapor barrier membrane is installed along the lower plane of the rafters, which will protect against moisture inside the room. The joints are glued with vapor barrier tape or reinforced construction tape. As always, a gap is left and the installation of the inner lining begins, which is attached to the crate with nails or self-tapping screws.

Insulation of floors along the logs is selected in two cases: attic ceilings and ceilings above basements with no heating.

- First, logs are installed and laid with roofing material to exclude rotting and destruction of the structure.

- Then the material of the heat insulator is installed inward. A knife with a blade length of more than 15 centimeters is used for cutting. The roll is simply rolled out between the logs so as to cover the entire space, and no additional fixing actions are required. Moistening of the material should be avoided during installation.

- The next step is the installation of an overlapping vapor barrier membrane, the joints are glued, as usual, with reinforced mounting tape or vapor barrier tape. A base is installed on top of the vapor barrier, which is attached with screws to the logs.

- Everything ends with finishing: tiles, linoleum, laminate or carpet.

When holding events for the purpose of soundproofing partitions the first step is to mark and collect the guides and their further installation.

- For a free-standing partition, one side must be coated with plasterboard, and you can start creating sound insulation.

- Isover is mounted between the posts of a metal frame without fasteners, tightly adhering to the structure and filling the entire space without gaps or gaps.

- Then the partition is sewn up on the other side with drywall, and the seams are putty using paper reinforcing tape.

Thermal insulation of baths and saunas begins with the creation of a wooden frame from 50 by 50 millimeters in size.

- The bars are mounted horizontally.

- The insulation is cut into two halves with a knife and installed in the frame, while the foil layer should be facing inside the warm room. As usual, the material is installed without gaps and crevices.

- The joints are well glued with foil tape, as well as the outer surface of the sheathing. All this will allow you to create a sealed vapor barrier circuit.

- A crate is placed over the horizontal bars to create an air gap. It will speed up the heating and increase the service life of the skin.

- At the final stage, the inner lining is installed.

One of the biggest mistakes when using Isover is choosing the wrong material width.

If a roll of insulation lies freely between, for example, beams, then the main goal will not be achieved. It will be quite costly to cut it into several rows, and leaving it in this state, despite the cracks and gaps, is completely pointless. Therefore, it is extremely important to calculate all the necessary dimensions for the work surface, taking into account the length, depth and width of the beams or lathing.

In the event that the insulation is in direct contact with wires or pipelines, it is imperative to check the tightness of the communications. In terms of electricity, the situation is not very dangerous, but in the second case, it is better to isolate communications using a corrugated pipe.

In addition, all materials must be completely dry at the beginning of the insulation process. If the surface for which the Isover is intended is damp, then you will either have to wait until it dries, or dry the room with a hairdryer or gun.

But the worst mistake, of course, will be the lack of waterproofing and vapor barrier. If these moments are missed, then the material will be wasted, and the thermal insulation effect will not be achieved.

How to calculate: instruction

It is very important to be able to correctly calculate the required thickness of insulation to create and maintain a comfortable temperature in the room. To determine it, it is necessary to reproduce the heat engineering algorithm, which exists in two versions: a simplified one - for private developers, and a more complex one - for other situations.

The most important value is the resistance to heat transfer. This parameter is denoted as R and is defined in m2 × C / W. The higher this value, the higher the thermal insulation of the structure. Experts have already calculated the recommended average values for different regions of the country with different climatic features. When building and insulating a house, it must be borne in mind that the resistance to heat transfer must be no less than the normalized one. All indicators are indicated in SNiP.

When building and insulating a house, it must be borne in mind that the resistance to heat transfer must be no less than the normalized one. All indicators are indicated in SNiP.

There is also a formula that shows the relationship between the thermal conductivity of a material, its layer thickness and the resulting thermal resistance. It looks like this: R = h / λ... R is the resistance to heat transfer, where h is the layer thickness and λ is the thermal conductivity of the layer material. Thus, if you find out the thickness of the wall and the material from which it is made, you can calculate its thermal resistance.

In the case of several layers, the resulting figures will have to be summed up. Then the obtained value is compared with the normalized for the region. It turns out the difference that the thermal insulation material will have to cover. Knowing the coefficient of thermal conductivity of the material selected for insulation, it is possible to identify the required thickness.

It is worth remembering that this algorithm does not need to take into account layers that are separated from the structure by a ventilated opening, for example, a certain type of facade or roof.

This is because they do not affect the overall resistance to heat transfer. In this case, the value of this "excluded" layer is equal to zero.

It must be remembered that the material in the roll is cut into two equal parts, usually 50 millimeters thick. Thus, having identified the required thickness of the insulation squares, the product should be laid in 2-4 layers.

- To calculate the required number of standard packs for roof insulation, the area of the insulated roof will have to be multiplied by the planned thickness of the thermal insulation and divided by the volume of one package - 0.661 cubic meters.

- To calculate the number of packages to use for facade insulation for siding or lining, the area of the walls must be multiplied by the thickness of the thermal insulation and divided by the volume of the package, which can be 0.661 or 0.714 cubic meters.

- To identify the number of Isover packs required for floor insulation, the floor area is multiplied by the thickness of the insulation and divided by the volume of one package - 0.854 cubic meters.

Safety engineering

When working with fiberglass insulation, it is imperative to use protective glasses, gloves and a gauze bandage or respirator. Clothes should be long-sleeved and long-sleeved, and socks should not be forgotten. Better, of course, to play it safe and wear protective overalls. Otherwise, installers will face unpleasant consequences - itching and burning all over the body. By the way, this requirement applies to all types of work with any mineral wool.

To protect the residents of the house from glass dust, it is recommended to put a special film between the insulation and the top layer, for example, clapboard.

Even if the wooden panel is damaged, the particles of insulation will not be able to penetrate into the room. You can cut the material with a simple knife, but it should be sharpened as sharply as possible, in extreme cases, you can use a fairly sharp chisel.

The insulation must always be stored in a dry, closed place, and the packaging must be opened exclusively at the installation site. The area should be well ventilated, and after completion of the work, all waste should be collected and discarded. Also, after completing the installation, you need to take a shower or at least wash your hands.

The pros and cons of Isover insulation are described in the next video.

The comment was sent successfully.