Liquid insulation: the choice of material for insulation from the inside and outside

Under the influence of the harsh climate and unfavorable weather conditions, residents of most regions of Russia are constantly thinking about insulating their living quarters. And for good reason, because the comfort in the house depends on the favorable temperature inside. According to statistics, about 90% of houses do not meet heat-saving standards. Of course, ultra-modern buildings are already being erected in accordance with the latest thermal insulation standards. But the walls of old houses need to be insulated, due to which heat losses will be reduced by up to 40%.

The huge selection of building materials on the modern market is impressive and often leads to a dead end, among them it is not easy even for professionals to navigate. Recently, thanks to new technologies, many new heaters with improved technical characteristics have appeared. One such material is liquid insulation. If you are still pondering the question of how to insulate your walls, then surely after reading this article you will decide on the choice of insulation material.

Peculiarities

In the construction industry, more and more compounds appear every year. Heat-insulating paint appeared not so long ago, but has already found its admirers, because it is difficult to find a replacement for it. In addition to facades and walls, you can even insulate your own car and various containers with it, and also use it in the production of agricultural products.

Many positive reviews are presented on construction forums about this product, which indicate that this type of thermal insulation is inexpensive, of high quality and easy to use. From the very beginning, the composition was developed for the space industry, but later builders also became interested in it.

The term "liquid insulation" means two different types of insulation: thermo-effect paints and foam insulation. Each of them has its own pros and cons, performance characteristics and technical properties.

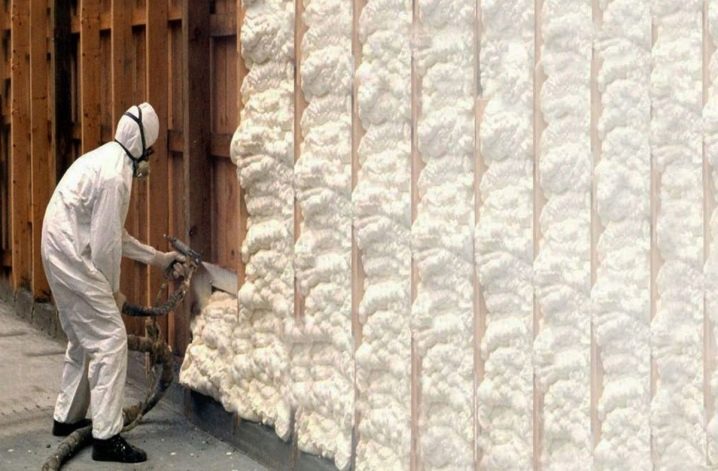

Liquid polyurethane insulation, produced in cylinders, is an innovative class of materials designed for insulation and sound insulation. It is often chosen for finishing difficult areas. With its help, you can insulate even a large area yourself. Suitable for thermal insulation of structures made of any material: metal, brick and concrete, for thermal insulation work in attics and attics.

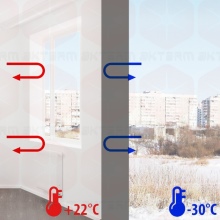

Liquid ceramic insulation based on ceramic glass is used to insulate walls outside the building, as a result of which natural heat exchange is established, therefore, the building will not cool down in winter and heat up in summer. In addition, this kind of insulation will protect the building from mold, rot and moisture. Thanks to such a treatment of the walls, the cost of heating the house will be significantly reduced.

Advantages and disadvantages

The advantages of foam liquid heat-insulating types of insulation include:

- effective reduction of heat loss and heat conservation;

- perfectly absorb sounds;

- easy to use, even for users with no construction experience;

- simple and quick installation;

- high degree of adhesion;

- environmental Safety;

- non-combustible;

- low consumption;

- not "loved" by mice;

- do not require special equipment for installation;

- have anti-corrosion and antiseptic properties.

For paints with a thermal effect, we highlight the following advantages:

- the liquid layer will not reduce the area of the space, since its maximum layer is no more than 3 mm;

- water-repellent properties;

- decorative effect with a metallic sheen;

- thanks to latex, the liquid insulation is moisture resistant;

- high-quality reflection of sunlight;

- heat resistance;

- minimal labor costs during installation;

- no load on the walls;

- increases the service life of treated pipes;

- high speed of processing large areas in a short time.

Liquid insulation is an irreplaceable thing when insulating hard-to-reach places.

Among the shortcomings, it should be noted that this type of insulation, such as heat paint, is not suitable for wooden walls made of timber or logs, and its sensitivity to temperature changes during storage and transportation is quite high.

Some buyers point to disadvantages such as the high price and the limited shelf life of open packaging.

Specifications

For the first time, polyurethane insulation was created by German scientists in 1973 on the basis of polyol and polyisocyanate. Now, depending on the composition of additional substances, up to fifty different brands of polyurethane foam are produced. This type of insulation is superior in many respects to its competitors. Water absorption is characterized by low absorbency, and high adhesion to various surfaces is the main advantage and feature of polyurethane foam. Hardening occurs within twenty seconds, and the resulting material will serve for at least thirty years.

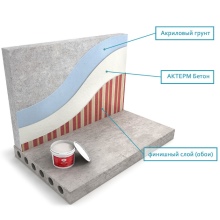

Thermal paint, or heat paint, in its appearance is no different from ordinary acrylic paint, even in smell. It is easy to apply, spread over the surface with a roller, brush or spray. It is used as insulation for walls from the inside and outside. The insulating components of the thermal paint are glass ceramic particles, titanium dioxide and latex, which gives stability and prevents cracking. It also includes acrylic, which plays the role of the base of the entire mixture.

Manufacturers claim that liquid ceramic insulation is a completely innovative insulation technology, according to which a 1.1 mm thermal paint layer can replace a 50 mm thick mineral wool layer... This indicator is achieved due to the presence of a vacuum thermal layer inside. And the shiny paint made of glass ceramics and titanium derivatives will protect the walls by reflecting infrared radiation. You can associate it with the coating of a thermos.

If you decide to paint the walls of your house, then it is best to immediately choose a thermal paint, so you will kill two birds with one stone - insulate the house and give it an aesthetic decorative zest with a metallic sheen.

Also, treating the internal or external walls of the building with a similar mixture, you will protect them from corrosion and fungus.

Views

Liquid insulation is presented in several types.

Penoizol and polyurethane foam

Both types are included in the foam group. If you look at them for the first time, you can easily confuse them with polyurethane foam. Important advantages of penoizol are good vapor permeability and low temperature (from +15) solidification, as well as fire safety. It does not burn and does not emit dangerous toxic gases.

Penoizol perfectly fills voids without swelling in volume. However, builders note such a minus of penoizol as the formation of cracks, which leads to its shrinkage over time and a decrease in thermal insulation. Another disadvantage is the impossibility of applying by spraying. This type of insulation can only be applied by pouring.

Polyurethane foam - a derivative of polyisocyanate and polyol... For many professionals in the construction business, it may be a discovery that liquid insulation based on polyurethane foam is produced in two versions: with open and closed voids.This moment has a serious impact on thermal conductivity and vapor permeability. The advantages of this type of thermal insulation are good adhesion to any type of surface, environmental friendliness, low sound conductivity and resistance to temperature extremes.

Both species are safe for human life and have excellent technical qualities. Is that the difference in price is quite significant - if you can insulate the house inside and outside with penoizol for an average price, then finishing with polyurethane foam will cost you much more.

Ultra-thin thermal paint

The simplest liquid insulation for walls and floors. Warming with this type of liquid thermal insulation is a very interesting process, similar to conventional surface painting. Insulating colorful mixtures have a unique composition and structure, which forms a thin thermal film.

Due to the fact that the film is very thin, insulation is carried out in several stages.

Ceramic-based warm paints deserve special attention, which, when dried, form a ceramic crust. You can apply this composition anywhere and in any way convenient for you: with a brush or a spray bottle.

Manufacturers and reviews

There are already a sufficient number of domestic and foreign manufacturers of liquid thermal insulation on the market.

Main manufacturers:

- AKTERM;

- Isollat;

- "Teplocor";

- "Tezolat";

- Astratek;

- "Thermosilat";

- Alfatek;

- Keramoizol;

- Thermo-Shield;

- Polynor.

- Odorless (some products from other manufacturers have an ammonia smell);

- The coating does not delaminate, the product does not even need to be stirred.

- Has less water absorption compared to analogues, the product is not afraid of water.

- Large application thicknesses up to 20 mm are possible.

- Dries quickly - 20-25 minutes at room temperature.

- After drying, the product becomes 15-20% stronger than analogues.

- The product is very easy to apply: the process is comparable to applying paint.

The most demanded creators of liquid thermal insulation are AKTERM, Korund, Bronya, Astratek.

Reviews about liquid insulation "Astratek" say that this is one of the best materials on the modern market, which has anti-corrosion properties and is able to withstand temperatures up to +500 degrees. The composition of thermal insulation based on polymer dispersion and special fillers is a homogeneous mass, similar in consistency to mastic, which is easy to apply with a brush or spray. Products from "Astratek" are high quality and safe.

When applying "Astratek" products, special brushes and sprayers are used, which will easily allow you to do the work yourself.

The minimum insulation service is fifteen years, but if all operating standards are observed, the term increases to at least 30 years.

Highly functional ultra-thin liquid-ceramic thermal insulation from Korund is a modern coating that is presented in a wide range on the market of any city in Russia.

"Korund" offers several types of insulation at once:

- "Classic" for processing walls and facades, as well as pipelines;

- "Winter" used to protect surfaces at subzero temperatures;

- "Antikor" used to treat areas prone to rust;

- "Facade" - special compound for exterior walls and façades.

Domestic products of the firm "Bronya" are also subdivided into several modifications: "Classic", "Antikor", "Winter" and "Facade" - everything is like the company "Korund". Also presented is "Volcano" - a mixture that can withstand temperatures over 500 degrees.

Norwegian Polynor on the basis of polyurethane became famous in Russia quite recently, but in such a short time it has earned the love of builders due to the fact that it can be used on any surface, and with the help of special nozzles, spraying is carried out without problems even in hard-to-reach places. The absence of seams reduces heat loss. Polynor is lightweight and environmentally friendly.

The average price for manufacturers is about 500-800 rubles per liter of liquid waterproofing.

How to choose a quality product?

In order not to be mistaken in the choice, having wasted money, you need to choose high-quality products for use in insulation. The lower the density of the dye mixture, the higher its useful thermal insulation properties will be.

After mixing a good warm paint, knead a drop between your fingers. If the surface is rough due to the presence of a large number of microspheres, then there is no doubt about the quality of the selected product.

Recommendations for use

Warming with liquid heaters is a fairly simple procedure that is carried out in several stages and is somewhat similar to staining with paint and varnish compositions. Before starting work, you should measure the total area of the room and purchase the required amount of thermal paint.

When purchasing, keep in mind that for better heat saving, the surface will have to be coated several times. Depending on the living conditions and climate, three to six coats of paint may be required.

Choosing a specific manufacturer, focusing on customer reviews and advice from professional installers.

Prepare the surface for the application of the mixture, clean it from dust, dirt, seal the cracks and seams with putty. To improve adhesion, treat the cleaned surface with a primer. The paint will never stick to dirty walls, peeling or leakage are possible. Work should only be done in good and dry weather conditions.

The first coat is applied as a primer. The final polymerization time is approximately one day.

Liquid thermal insulation can also be used over the putty, and after application it can be finished with wallpaper or ceramic tiles.

Liquid ceramic insulation can be applied using an airless spray or a special roller. The roller should have a medium-length pile, so it will capture more paint at a time. Do not forget to thoroughly mix the composition with a construction mixer before use. Avoid gaps, paint the wall in small areas. The corners of the house and other hard-to-reach places are painted over with a brush.

Apply the next layer only after the previous one has completely dried. If you applied the first layer with horizontal movements of the roller, then the next one should be painted with vertical ones. Thus, you will strengthen the insulation.

Sandwich technology can be used to insulate very hot pipes. This practice involves alternating layers of liquid ceramic coating with layers of fiberglass five times. If you want a flawlessly even surface, then apply a regular bandage or cheesecloth to the finishing layer and cover with KO85 technical gloss varnish.

Recently, there has been a great demand on the market for foam liquid insulators and equipment for their use. In terms of the complexity of installation, liquid foam insulation differs from mineral wool and other materials for the better. The whole process can be done alone, without assistance. For example, comparing with roll or block heaters, foam allows you to perform installation in a short time, literally in a few hours. And financially, they also benefit significantly.

The principle of operation is simple: after you have prepared the surface, spray the foam from top to bottom. Adjust the flow rate using the valve release on the assembly gun. The layer thickness should not exceed five centimeters.

Useful Tips

- When working with thermal paints, be sure to wear a respirator. It is very easy to breathe in vapors, despite the fact that the paint dries very quickly.

- Before applying the foam insulation in the cylinder, shake it for three minutes.

- Polyurethane insulation can irritate eyes and skin when applied, so use special construction goggles and a protective suit.

- The better you level the surface of the coating, the better the thermal insulation will be and the less material will be lost.

- Prepare the thermal insulation mixture of thermal paint immediately before use. Repeat mixing every half hour, do not allow the paint to delaminate.

- Some formulations that have a thicker consistency, if necessary, are diluted with plain water.

- If you are using foam insulation to insulate holes, then before starting to fill the space, run a stream of air from the compressors into the slots and check for dead zones.

- Always work from top to bottom.

- When insulating, it is possible to combine several insulating materials. For example, walls can be insulated with mineral wool, hard-to-reach places can be filled with penoizol, and the floors can be painted with liquid ceramics.

- At the end of work with insulation based on polyurethane, the assembly gun must be cleaned with a liquid solvent.

- Uncured foam can be washed off immediately with water.

- If you want to insulate the facade, then it is better to choose liquid heaters labeled "Facade" from the company "Korund" or "Bronya", which are intended specifically for exterior wall decoration.

- Each manufacturer indicates instructions with recommendations for application on the packaging. Strictly follow all the instructions provided so as not to violate the technology.

- When choosing a heater, be guided by your financial capabilities, as well as the principle of operation.

- Assess your strengths and resources. If you are not sure that you can do it, then trust the specialists so as not to waste time and money in vain.

For information on how to use liquid thermal insulation, see the following video:

We are renting an apartment with the girls for the 3rd year, the windows on the embankment - the view is awesome! But! Every winter, as soon as the frost set in, the corner of the large room seemed to be damp and cold was blowing from it. Eventually, in the spring, the wallpaper began to lag behind. They turned to the hostess, said: the houses were built like that, I don't know what to do! We decided to prepare ourselves before the beginning of winter. I have read articles on thermal insulation. We decided, with the permission of the hostess, to get rid of the old light green wallpaper and coat the walls and corners with liquid thermal insulation.

The comment was sent successfully.