Insulation XPS: description and specifications

The modern market offers customers a wide range of different types of heaters. The material is used not only in regions with harsh winters and capricious weather conditions. It is a practical tool for creating comfortable temperature conditions in various types of premises: residential buildings, government agencies, warehouses and much more.

Extruded polystyrene foam, which is abbreviated as XPS, is very popular. Let's talk about the characteristics and use of the material in more detail.

General characteristics and use

Insulation is used for cladding:

- balconies and loggias;

- basements;

- facades;

- foundations;

- expressways;

- blind area;

- runways.

The material is used for cladding horizontal and vertical surfaces: walls, floor, ceiling.

Renovation specialists point out that XPS boards are among the most common insulation materials. A wide range of applications and technical features played an important role in the popularity of the products.

Due to the high demand in the market, you can often find products from unscrupulous manufacturers who disrupt the manufacturing process. As a result, customers run the risk of buying a low-quality product. Any inaccuracies in production cause a significant reduction in the service life of the insulation and its characteristics.

You will learn more about how to use extruded polystyrene foam in a residential environment.

Colour

The standard XPS color is white. This is the most common option. However, the insulating finish can be silver in color. The color changes due to the inclusion of a special component - graphite. Such a product is designated with a special label. Silver plates have increased thermal conductivity. The characteristic is achieved by adding nanographite to the raw material.

It is recommended to choose the second option if you want to purchase the most reliable, practical and effective insulation.

Dimensions (edit)

XPS insulation comes in a variety of sizes. The most common sizes: 50x585x1185, 30x585x1185, 20x585x1185, 100x585x1185, 1200x600x50 mm. Choose the appropriate option depending on the size of the structure. If necessary, the canvases can be trimmed without problems.

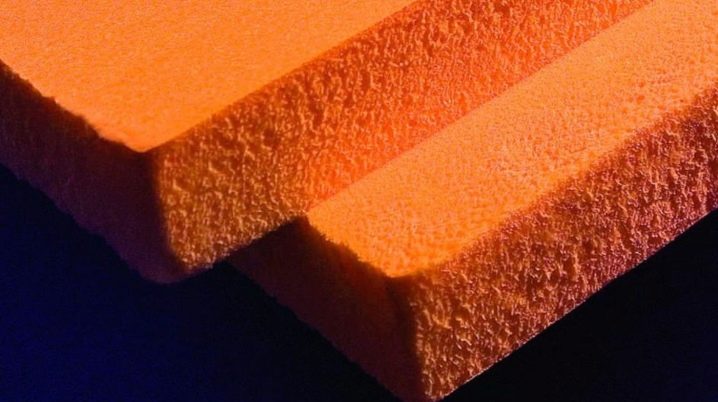

Structure

Extruded polystyrene foam, made according to all the rules, must have a uniform structure. Be sure to evaluate this when purchasing a finishing material. There should be no voids, grooves, seals or other defects on the canvas. Flaws indicate poor product quality.

The optimum mesh size ranges from 0.05 to 0.08 mm. This difference is invisible to the naked eye. Low-grade XPS insulation has larger cells ranging from 1 to 2 mm. The microporous structure is essential for the effectiveness of the material. It guarantees minimal water absorption and high efficiency.

Weight and density

There is an opinion that reliable and durable thermal insulation should have a high density, which is denoted as weight per m³. Modern experts consider this to be wrong. Most manufacturers use low density extruded polystyrene foam, while maintaining the quality of the material.This is due to the cost of XPS's main raw material, polystyrene, which is over 70%.

In order to save raw materials (stabilizers, foaming agents, colorants, etc.), manufacturers deliberately make the boards denser in order to create the illusion of quality.

Outdated equipment does not make it possible to produce durable XPS insulation, the density of which is less than 32-33 kg / m³. This indicator is not able to increase the thermal insulation properties and does not improve the performance in any way. On the contrary, unnecessary pressure is created on the structure.

If the material was made from carefully selected raw materials on innovative equipment, then even with a low weight, it will have a high density and excellent thermal conductivity. To achieve this result, it is necessary to comply with the production technology.

The form

By evaluating the shape, you can also say a lot about the quality and efficiency of the material. The most practical XPS boards have an L-shaped edge. Due to it, installation is faster and easier. Each individual sheet is overlapped, eliminating the possibility of cold bridges.

When using plates with standard flat ends, foaming will be necessary. This is an additional repair process that requires not only time, but also financial investments.

Thermal conductivity

The main characteristic of the material is thermal conductivity. To verify this indicator, it is recommended to demand from the seller the corresponding document. Comparing the certificates for the goods, you can choose the highest quality and most reliable insulation. It is almost impossible to assess this characteristic visually.

Experts identify the optimal value of thermal conductivity, which is about 0.030 W / m-K. This indicator can change up or down depending on the type of finish, quality, composition and other aspects. Each manufacturer adheres to certain criteria.

Water absorption

The next important quality to pay attention to is water absorption. You can visually evaluate this characteristic only if you have a small sample of insulation with you. It will not be possible to evaluate it by eye. You can conduct an experiment at home.

Put a piece of material in a container of water and leave for a day. For clarity, add a little dye or ink to the liquid. Then estimate how much water is absorbed into the insulation, and how much has become in the vessel.

Some experts use the prick method when evaluating a product. Using a conventional syringe, a little liquid is injected into the web. The smaller the spot sizes, the better and more practical the XPS finish.

Strength

XPS quality insulation boasts excellent durability, even at mid-weight. This characteristic is important during the installation process. Durable slabs are easy and convenient to cut and attach to the structure. Such material does not pose any problems during transportation and storage. High strength allows you to keep the shape of the slabs for a long time without fear that the material will turn into dust.

If during the installation process you notice the formation of cracks, chips, deformation, and also hear a crack, it means that you have purchased a low-quality product. Be as careful as possible during the installation process so as not to damage the slabs.

Environmental friendliness and safety

Premium extruded polystyrene foam is an environmentally friendly finish that is completely safe for health and the environment. On the domestic market, there is only one type of XPS material on sale, which has been awarded the Leaf of Life certificate. The document officially confirms the environmental friendliness of the products. The material is safe not only for people, but also for animals and the environment.

The use of XPS insulation fully complies with the norms of SNiP 21-01-97. This regulation refers to the section "Fire safety of buildings and structures".SNiPs - approved rules and regulations in the construction industry.

Reviews

Let's summarize the article with opinions about XPS insulation. The Internet has collected many responses about the product, both laudatory and negative. It's safe to say that most of the reviews are positive. Buyers note qualities such as environmental friendliness, easy installation, excellent performance and much more.

Customers who were unhappy with the purchase said that more effective and practical insulation can be found on the domestic market.

The comment was sent successfully.