Description of rolled insulation: what are they and how to choose?

When insulating large areas, the best efficiency is shown not by insulation boards, but by rolls with insulation. The same applies to pipes and ventilation ducts. Their main difference is the increased density, and the consequence to this is the high rigidity of the coating, which makes it possible to insulate objects with non-standard geometry much better.

Features of the species

There are several types of insulation, they are mainly divided by composition.

Minvata

One of the most common in the Russian market is a mineral wool-based heat-insulating material. This is mainly due to the combination of price and technological properties of the material itself. It is very easy to operate. It is advisable to choose a white, soft and self-adhesive material for the timber.

The name "mineral wool" is inherent in many thermal insulation materials, which are different in their composition and properties. Insulation is not particularly popular, which is made by melting some rocks with the formation of certain fibers. During production, these fibers are woven into a single carpet, this wool is called "basalt". For any resident of Russia and the CIS, the term "glass wool" is also familiar.

This insulation material is an outdated technology, but due to its price it is still in demand today. It is made by melting broken glass into single fibers. There is also cotton wool obtained in the process of melting waste from the metallurgical industry (slag wool).

Due to the raw materials used in its manufacture, its price is much lower than that of glass wool or basalt wool.

Features, pros and cons

Cotton wool differs from each other in technical characteristics. Glass wool has a high temperature threshold of 450 degrees, after which the material acquires irreversible damage. The density of glass wool is 130 kg / m3, and the thermal conductivity is about 0.04 W / m * C. This material is not flammable, it does not smolder, it has a high vibration and sound absorption threshold.

There is practically no shrinkage over time, including long-term versions.

The disadvantages include the fact that when water gets in, all the positive properties of this material come to naught. Glass wool is a rather fragile and brittle material. On contact with the skin, it causes irritation, itching, which is difficult to remove.

If it enters the eyes, it can seriously harm them, as well as if it enters the nasopharynx. You need to work with such material in closed clothing.

Basalt wool can withstand high temperatures (up to 710 degrees). Its thermal conductivity is about 0.04 W / m * C, the density varies in the range of 210 - 230 kg / m3. Unlike glass wool, this material is not afraid of moisture, and also does not lose its properties. When in contact with the skin, the roll insulation does not cause irritation or itching.

Slag has the largest mass and density. Its density fluctuates in the region of 390 - 410 kg / m3, and its thermal conductivity is about 0.047 W / m * C. However, its temperature maximum is much lower (about 300 degrees). Slag wool melts, in the process of melting its structure is also destroyed, and irreversibly.

The sizes of these materials vary depending on the manufacturer's established standards. However, the most common ones are:

- length from 3 to 6 m;

- standard width 0.6 or 1.2 meters.

Some manufacturers make other dimensions in width (0.61 m). The thickness of the cotton wool is standard (20, 50, 100 and 150 mm).

Foil material

Often, one side of the insulation is covered with a layer of foil-clad material. This allows you to keep the coating from moisture and ultraviolet rays. Most often, such materials are used for internal insulation of premises, the wool itself can be absolutely anything. The types of such material are varied. These include expanded polystyrene, cork, polyethylene.

The most popular material on the market is expanded polystyrene. It is very practical and inexpensive. It copes well with sound insulation and vibration. The roll length is usually 10 m, the width does not exceed 0.5 m. This material copes well with moisture and fungus. However, in terms of the degree of thermal insulation, it is significantly inferior to foamed polyethylene.

Cork thermal insulation is characterized by high strength, low weight, harmlessness and good appearance. For wet rooms, it is recommended to use wax-impregnated cork flooring. The dimensions of this material are the same as for expanded polystyrene. Foamed polyethylene is a pretty good material. It represents small cells with air, cardboard or paper is located at the edges.

The substrate is secured by lamination. Due to this, it is possible to achieve the most durable and reliable connection with any type of base. The roll insulation has good heat-conducting characteristics. Depending on the purpose, there are foil and metallized coatings.

For vapor reflection, a foil type of material is more suitable; for vapor containment, a metallized spraying is necessary.

The spraying is very fragile and is damaged by minor mechanical influences. The foil material has excellent heat reflecting characteristics. It is less susceptible to mechanical damage. Today, a silvery material with a reflector is quite popular.

Manufacturers and selection criteria

One of the leading companies in the production of roll insulation is a German company Knauf... A distinctive feature of the product is the absence of formaldehyde. In addition, the materials are characterized by ease of use. This company supplies almost every roll with installation instructions, which will allow novice builders to do the insulation work better. Due to the composition, insects (beetles, ants) and rodents (rats) cannot settle in such thermal insulation.

The French brand is no less famous. Isover... This company has a huge selection of roll-type heaters. Foil rolls are also available. The products of this company are used for insulation of internal premises, as well as outside of buildings.

Due to its composition, it is fire-resistant, does not support combustion in the event of a fire or short fire, and self-extinguishes.

The most common Spanish company in the European part of Russia URSA... Its products are somewhat cheaper than the French brand, the assortment is in no way inferior to it, which makes the materials in demand among the buyer. The company gives a very long guarantee for its products, it is better to clarify the exact figures of the guarantee immediately before buying.

The cheapest insulation is produced by a domestic brand TechnoNICOL, which is aimed at middle-income people. The quality of this material is incomparable with foreign counterparts, but the insulation is in great demand by people who are engaged in their own construction of summer cottages or private houses. In view of the price, this is the favorite insulation for management companies and other organizations that want to do something big for little money. Differs in its quality and mineral wool "Warm House".

When buying, it is important to remember that different types of premises require different insulation, as well as ceiling insulation is highly undesirable for use on the floor (and vice versa).

Wall insulation has its own characteristics, because the purpose of each type of insulation is slightly different, as are the properties. Some points also depend on the material of the structure on which the rolled thermal insulation is attached. It is necessary to look at how moisture affects the material in order to take this into account when choosing.

Installation technology

The technology of installing roll insulation is slightly different from plates. Initially, they begin to insulate the walls or floor. The walls are mostly made of slabs, as is the straight ceiling. Therefore, often, the floor and pitched ceiling-walls are suitable for insulation and installation. When insulating the floor, it is worth looking at what type of insulation is available.

Insulation in foil is mainly used, but sometimes the rolls of insulation are covered with ordinary heat-insulating foil or metal film. The insulation should move 1 cm away from the walls. This is due to the fact that when the temperature changes, the material contracts and expands. Lack of free space in a metallized or foil-clad insulation leads to its deformation and damage over time.

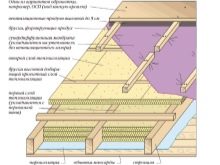

Ceiling (pitched) insulation is attached between the rafters, cutting out a little more in order to insert better between the boards. Insert them strictly from bottom to top to avoid voids. After installation, the surfaces are clamped with main profiles or boards for applying additional (for example, vapor barrier) materials on top. The work is carried out very carefully.

Let's move on to the installation of walls with roll-type insulation from the inside. It is produced by preparing the walls for pasting. They dilute a special glue for cotton wool, the wall should not be in putty or plaster, only bare concrete or brick is allowed. The composition is applied to the wall evenly under a special comb, after which they begin to glue the rolls, which can be cut for convenience.

In this case, it is advisable to make the wall itself in a level, a plane, if there are no further plans for sewing in a box or gluing fiberglass. After the material is mounted on the wall, you need to screw it on, Each petal should be slightly sunk into the cotton wool. For 1 m2, at least 5 fixing holes are required. It is better to fasten the sheets themselves and the space between them (in this case, both sheets will grab, which will avoid warping, bring the level and plane).

After the sheets have set, a layer of glue should be applied. The technology resembles filling, only with a different solution. It is important to keep track of the level and level. It is necessary to make at least two passes, since it will be problematic to put a good layer the first time. After alignment, regardless of the type of room, you can proceed to the next work. When installing drywall sheets inside the house, they are fastened by means of dowels to a layer of thermal insulation, which it is desirable to process with glue, as in the previous paragraph.

For the advantages of URSA roll insulation, see the video below.

The comment was sent successfully.