Insulation perlite

There are many different types of insulation. A very popular variety is such an insulating material as perlite. It has a lot of positive qualities, so many consumers choose it. In this article, we will tell you about its features and characteristics.

Advantages and disadvantages

Expanded perlite, characterized by a porous structure, is often used to insulate various structures. This is a very popular insulation material that has many advantages. Let us examine in detail the most serious of them.

-

This insulating material is characterized by lightness. Thanks to this feature, perlite can be freely placed in the interior of almost any frame-type structure. At the same time, additional strengthening of the strength of these structures can be dispensed with.

-

Perlite is a heater that does not suffer from sudden temperature jumps. Since the material has such an advantage, it can be used for outdoor use regardless of weather conditions. High-quality insulation is able to withstand exposure to temperatures from –220 to +900 degrees Celsius without negative consequences.

-

Many users are captivated by the fact that perlite is an environmentally friendly and safe material. In absolutely any operating conditions, it does not turn out to be toxic.

-

Perlite is not an allergen to animals or humans. It does not provoke "violent" reactions from living organisms.

-

The insulating material in question demonstrates high durability. in relation to the effects of most alkaline and acidic compounds.

-

This insulation is not susceptible to destructive corrosion.

-

Due to the characteristic density parametersthat arise between the particles of the insulating material during the laying of its layers, it is possible to achieve very high sound insulation values of the entire base structure. For this reason, there is no need to use an additional layer of insulating material of a different origin.

-

Perlite is completely unaffected by deformation processes from exposure to high temperature values of the household level. The material is perfect for high-quality installation of underfloor heating systems in various rooms.

-

The cost of this insulating product is also attractive. If you compare the price of perlite with other materials in a similar category, you will notice that it belongs to the middle price category.

-

The effectiveness of the insulation under consideration is quite high, so it can be confidently considered rational, ergonomic and most practical in its main application.

Despite the fact that perlite has many advantages, it also has its disadvantages. Before you start working with this insulating material, it is advisable to familiarize yourself with them.

-

The main disadvantage of perlite is its increased fragility. The mineral that underlies this insulation can surprisingly easily collapse, turning into dust. Such a product is capable of significantly losing weight during transportation by an open method. During backfilling, this also causes a lot of problems.

-

It is necessary to work with perlite only in protective equipment. We are talking about glasses, gloves and a respirator. In order for the sandy composition to be dusty to a minimum, before use, they resort to wetting it with water.

-

In some cases, this insulation turns out to be more expensive than certain of its counterparts.

-

The material in question is characterized by the ability to cake. Over time, it shrinks noticeably, reaching 10% or more.

-

Perlite is an insulating material that has many areas of increased thermal conductivity, a lot of heat can go through them.

-

Another drawback of the insulating material under consideration is associated with the difficulties that arise during its reconstruction. If for some reason it is necessary, for example, to cut openings in floor structures where there is a perlite insulation, then this will certainly provoke its rash.

The listed disadvantages of perlite are quite serious, so the user must take them into account before purchasing such a heater.

Specifications

Let's find out what properties and technical characteristics are typical for the considered type of insulation material.

-

Perlite is characterized by thermal conductivity values ranging from 0.043 to 0.052 W / m * K.

-

The moisture content of perlite by weight is no more than 2%.

-

As for the uneven distribution of grains in the structure of this insulation, there is an indicator of up to 15% in terms of the total volume of the product.

-

The moisture absorption rate here reaches 400% of the own weight of the insulating material.

The insulation in question is chemically neutral. The action of alkalis and acids does not affect it in any way. In addition, high-quality perlite does not lend itself to destructive decay if exposed to moisture.

Perlite does not contain dangerous microorganisms or rodents. This type of heat insulator is used over a very wide temperature range.

It does not contain heavy metals and other hazardous components that can harm the health of living organisms.

Views

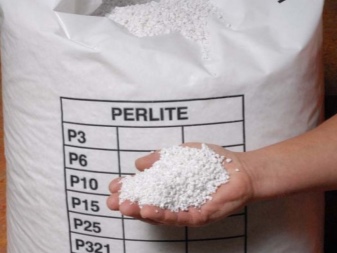

There are several distinct subspecies of perlite. Each of them has its own parameters, application features and characteristics.

-

Loose form, or sand, is characterized by lightness. Insulation in this form is lighter than all its other varieties. That is why free-flowing perlite is so often used for high-quality insulation of partitions, as well as for the simultaneous lightening of the structure of almost any building. By means of the insulation under consideration, it is possible to eliminate slit-like and interfloor layers. You can fill in other existing voids.

- Perlite is also sold in the form of slabs. This is one of the most common forms of this insulation material. Products in the form of slabs are very well sold out, since they are characterized by a convenient structure. Mounting them is also easier and more convenient. Insulation plates are distinguished by high levels of hygroscopicity, so it is advisable to use them specifically for internal installation work. If the insulation boards are installed outside, they must be supplemented with a special moisture-proof coating.

- Perlite bitumen is a roofing variation of the considered insulation. With this product, the installation of insulation structures is as simple and hassle-free as possible. The roofing product is characterized by increased flexibility. It is suitable for any roof and structure of any complexity.

- There are also dry mixes intended for construction work. They are made with the addition of fine-grained perlite and cement mixture. In such a mass, it is usually necessary to add only the appropriate volume of water in order to obtain a solution completely prepared for all work.

Coating insulation technology

Plates or bulk insulation components can be supplied to various foundations of the house. Perlite is often used to insulate floors, attic, attic, ceiling, roof and many other substrates. It is allowed to be used for installation under a screed for a water-heated floor. This speaks of the versatility and practicality of this insulating product.

Perlite very often insulates walls in a wooden or brick house. For block buildings, such an insulating material is also perfect.

Let's consider how to properly mount perlite using the example of wall insulation in a house.

-

For such work, a bulk type of insulation material is perfect.

-

First, you will need to carry out a number of preparatory work. They should be started already in the process of erecting the walls of the dwelling.

-

The ideal solution would be to use the sand fraction of the insulating material in question. Its volume is calculated in the range of 60-100 kg per cubic meter. m.

-

The finished product is poured directly into the inter-wall space. This will need to be done periodically, namely, upon completion of the laying of each of the parts of the wall of the house.

-

In order to prevent further shrinkage of the insulating product in question, it is carefully tamped by means of the usual tapping.

Most often, perlite material is used for high-quality insulation of floors in the house. When it comes to solid monolithic surfaces, it is best to use sand from this product.

It fits easily.

-

Perlite sand from the bags is poured onto the base of the floor.

-

By means of special slats, the material of a free-flowing consistency is evenly distributed over the entire surface of the base.

-

Absolutely all pipes must be immersed in a composition laid in an even layer.

-

After that, the surface of the floors can be covered with slabs.

If it is necessary to insulate wood-covered floors, the sealing of the insulating material will not be required. It is enough to pour perlite sand into the gaps that exist between the wooden components of the flooring. Strengthening of thermal insulation can be carried out by means of fiberboard plates laid out in one layer. And also fiberglass is perfect for these purposes. Some craftsmen prefer to use cement for strengthening. The entire insulated surface should be sprinkled with a dry solution, and water should be sprinkled on top.

The comment was sent successfully.