Expanded polystyrene PSB-S 25: technical characteristics and scope

The modern market for heat-insulating building materials offers a wide range of products to the attention of buyers. The leading position among them is occupied by expanded polystyrene. It can be of several types depending on the manufacturing method and the composition of the raw materials. The most popular is PSB-S 25 expanded polystyrene.

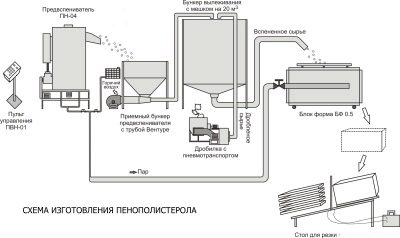

Manufacturing

The principal feature of the production of expanded polystyrene is the effect of steam on the polystyrene granules enriched with gas and placed in suspension. In this case, a multiple increase in particles is observed, which is accompanied by their displacement from the mold and sintering among themselves. In this way, a granular mass is formed, the bulk component of which is predominantly gas.

This structure and composition of the material directly affects its heat and sound insulation characteristics.

Specifications

The technical characteristics of expanded polystyrene correspond to GOST 15588-86. In the regulatory document, the abbreviation of the product is deciphered, where:

- PSB refers to the production method;

- C indicates the presence in the composition of fire retardants that improve fire performance;

- The number 25 indicates the density per m3.

Expanded polystyrene PSB-25 has several advantageous characteristics over other materials. It is worth highlighting the main ones.

- Thermal conductivity. The coefficient fluctuates in the range of 0.038-0.043 W / m-K.

- Water vapor permeability. This indicator indicates the removal of moisture from the room through the materials used. In this case, the indicator is 0.05 Mg / (m * h * Pa).

- Water absorption. An indicator characterizing the ability of a material to absorb moisture. Measured as a percentage of the volume in 24 hours. PSB-25 has an indicator of no more than 2%.

- Destruction temperature. The indicator of the destructive (destructive) temperature is 160 degrees. This material belongs to the class of hardly flammable materials and has the ability to self-extinguish.

- Durability. Due to the wide range of degradation temperatures, PSB-25 is not significantly affected by destructive external factors. In the event that it is not directly exposed to ultraviolet rays, interaction with solvents and acid concentrates, the service life is at least 80 years.

- Good compressive strength and high flexural strength. These values for PSB-25 are 160 and 250 kPa.

- Environmental friendliness and hygiene. This material is widely used to create food packaging.

The dimensions of PSB-S 25 are spelled out in GOST. It is produced in the form of plates, the standard length of which is from 900 to 5000 mm. At the same time, the indicator of width varies in the range from 500 to 1300 mm, thickness - from 20 to 500 mm.

Manufacturers indicate the dimensional characteristics of PSB-S 25 in the following format: 1200x1000x60 mm, where:

- 1200 and 1000 are the length and width of the sheet;

- 60 mm is its thickness.

The indisputable advantages of polystyrene include the low cost relative to similar materials with a higher density, as well as ease of installation. It is known that the use of additional equipment and tools significantly increases the cost of finished objects. Polystyrene is lightweight and does not require the use of a crane when climbing to the floor. It can be cut with an ordinary knife, while the sheet is quite simple to give the required shape.

The disadvantages of PSB-S 25 include its flammability, despite its rapid attenuation, as well as fragility during operation.

Scope of application

The advantages of polystyrene, its physical characteristics allow the productive use of this material in various fields. Expanded polystyrene is used for insulation of roofs, attics, floors, walls. Due to its high strength indicators, PSB-S 25 perfectly withstands the load from the roof directly resting on the slab.

It is used to create heat and sound insulation of buildings.

Also, expanded polystyrene PSB-S 25 is used as a middle layer in the production of sandwich panels. They insulate water pipes from freezing, use them for packaging. For external thermal insulation of facades, an analogue with the marking PSB-S 25 F. is better suited.It is designed specifically for external work with subsequent plastering and painting of walls. This material is suitable for curly cutting, creating volumetric facades.

The financial benefit from the use of PSB-S 25 expanded polystyrene is obvious. It allows you to reduce the cost of heating buildings, create an effective and durable thermal insulation system.

In buildings insulated with polystyrene, the most comfortable living and working conditions are created.

PPS-25, like PSB-S 25 (M25), is used for insulation. The difference lies in the fact that the denser and more durable PPS-25 is better suited for use in places with significant loads (such as parking lots, underground grounds, lawns, sports grounds, skating rinks). PPS-25 is also used for waterproofing underground utilities. It can be easily replaced with PSB-S 35 without deteriorating the technical characteristics of the work performed.

For more details on the technical properties and scope of PSB-S 25, see the next video.

The comment was sent successfully.