Non-combustible insulation: how to choose safe thermal insulation?

Non-combustible insulation is very popular due to its wide range of applications. What types of non-combustible insulation are there? What material to use for a specific construction task? This will be discussed in our article.

Peculiarities

A non-combustible material for thermal insulation must meet the following characteristics:

- burning with a visible flame is possible, but its duration does not exceed 10 seconds (that is, the insulation can catch fire, but ignition with the presence of an open flame lasts no more than the specified time);

- at the moment of combustion, the temperature of the insulating material does not rise above 50 ° C;

- during combustion, the insulation cannot lose more than 50% of its weight and volume.

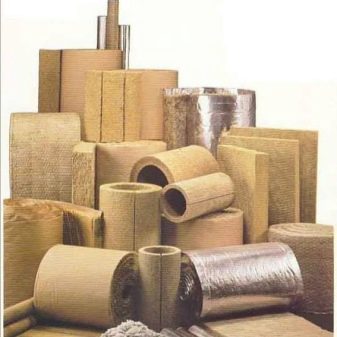

Types and properties

Insulation can have a different basis and production technology, which determines its appearance and technical characteristics. Let's consider the main types of non-combustible heat-insulating material.

Loose

They are stones and formations of various fractions, which are poured into the space of the building structure. As a rule, for greater thermal efficiency, it is recommended to use bulk insulation of different sizes: the larger ones provide thermal insulation, the smaller ones fill the space between them.

Bulk types of non-combustible insulation include the following materials.

- Expanded clay. Environmentally friendly material based on clay. Suitable for thermal insulation of hard-to-reach places. In addition to high thermal insulation characteristics, it is moisture resistant. Expanded clay is the best suited for the insulation of fire hazardous facilities, it has long been used in the organization of industrial furnaces.

- Expanded vermiculite. The product is based on hydromica, which is subjected to high-temperature firing. Usually, using this material, thermal insulation of low-rise buildings, as well as attic rooms and external thermal insulation is carried out. Differs in environmental friendliness and improved indicators of biostability, among the disadvantages is the inability to withstand the effects of moisture. It can be leveled only by high-quality and correctly mounted waterproofing.

- Perlite. The material is based on volcanic glass, which provides low thermal conductivity and low weight. Only 30 mm of perlite can replace a 150 mm layer of brickwork in terms of thermal efficiency. Among the disadvantages are low moisture resistance.

Honeycomb

Outwardly, such heaters look like frozen soapy foam. The most common fire-resistant cellular insulation material is foam glass. It is produced by sintering glass chips with coal or other blowing agent. It is characterized by durability (service life reaches 100 years), mechanical strength, low thermal conductivity.

Foam glass does not burn even at record high temperatures, it is only possible to melt the material without releasing dangerous toxins. The material is moisture resistant, but quite heavy, dimensional, so basements are the best place for its use.

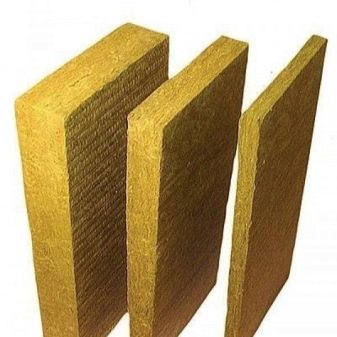

Fibrous

Outwardly, the material resembles cotton wool, since it consists of chaotically located thinnest fibers of a white or milky shade. Such heaters are called “cotton wool”.Release form - rolls or mats.

Mineral wool is also sheet. Sheet products have lower rigidity compared to counterparts in mats. If we talk about fire-resistant fiber insulation, then they include several types.

- Glass wool. Withstands heating up to 500 ° C, while maintaining its technical characteristics. These include thermal efficiency, durability, light weight. However, the material is prone to shrinkage, and during work requires special protection, since thin fibers prick, dig under the skin, and the smallest particles irritate the mucous membranes of the upper respiratory tract.

- Basalt wool. Basalt wool is based on fibers from rocks that are preliminarily heated to over 1300 ° C. This is due to the ability of cotton wool to withstand exposure to high, up to 1000 ° C, temperatures. Today, stone wool is one of the best heat-insulating materials: it has a low coefficient of moisture absorption, is vapor-permeable, does not shrink, is environmentally friendly and bio-resistant.

- Ecowool. It consists of 80% recycled cellulose, which has undergone a special flame retardant treatment. The material is environmentally friendly, has a low weight and a low coefficient of insulation, but low moisture resistance.

Liquid

The raw material is sprayed using special equipment, after hardening, it forms a mass, in appearance and to the touch, reminiscent of expanded polystyrene. The most famous type of liquid fire-resistant insulation is liquid polyurethane.

It is characterized by environmental friendliness, and thanks to the method of application and improved adhesive properties, it is evenly distributed over the surface, filling cracks and joints. This, firstly, ensures the durability of thermal insulation, and, secondly, guarantees its quality and the absence of "cold bridges".

Criterias of choice

- Achieve high thermal efficiency it is possible by choosing a heater with a low coefficient of thermal conductivity. In addition, we must not forget that when a room is insulated, only 20-25% of the heat loss falls on the walls. In this regard, the approach to the issue of insulation should be comprehensive, the maximum effect can be achieved only by creating an absolutely sealed structure.

- An important criterion is the cost of the product. It should be remembered that high-quality insulation cannot be cheap. An unjustified price reduction means a violation of the insulation manufacturing technology, which directly affects its technical features.

- When buying modern mineral wool insulation pay attention to the location of the fibers... Preference should be given to products with a chaotic arrangement. Unlike analogs with horizontally or vertically oriented fibers, they are characterized by higher heat and sound insulation values.

- Fire resistant facade material, in addition to low thermal conductivity, should demonstrate good moisture resistance and biostability. To decorate a house inside, the characteristics of environmental safety and the absence of toxic substances in its composition are important.

- If the mineral wool insulation is not exposed to loads (for example, it is laid on the frame or between the supporting structures), you can choose a less dense (up to 90 kg / m3) option. It's cheaper. If pressure is applied to the material, then the indicators of strength and tensile and compressive strength become important.

These qualities are demonstrated by denser (semi-rigid and hard rigid) counterparts, which are distinguished by a higher cost.

Scope of application

Despite the fact that all heaters are used to maintain the specified temperature parameters inside the room or equipment, different types of it have different purposes.

The most widespread is basalt wool. It is used more actively than other non-combustible materials for external insulation of facades.It is noteworthy that cotton wool is equally effective for use both under plaster and in the curtain wall system. It allows you to organize very high quality ventilated facades.

Mineral wool is also used in these works, but much less often. This is due to the worst indicators of moisture resistance and vapor permeability of mineral wool, as well as its tendency to shrinkage.

However, having greater elasticity, mineral wool is optimal for finishing structures of complex shapes, production units.

For insulation of an unexploited attic, as well as a layer of floors on the first floors of buildings, it is best to use bulk materials, for example, expanded clay. For rooms characterized by high humidity (baths, saunas, houses located near water bodies), it is important to select a moisture-resistant and vapor barrier insulation. These requirements are met primarily by stone wool.

For insulation of residential premises (floor, walls, ceiling, partitions) Basalt wool is mainly used. For insulation of horizontal surfaces, primarily the floor, it is more convenient to use roll materials, for example, mineral wool. The same material is widely used for thermal insulation of wooden buildings. Mineral wool canvases are laid on the inside of the building between the load-bearing rafters.

For filling voids in masonry bulk materials are usually used. It should be remembered that when heated, expanded clay begins to emit toxic substances, so its choice is not the best option for a bath. More environmentally friendly bulk fillers - expanded vermiculite and perlite. The first, however, is extremely susceptible to moisture. Perlite is ideal for filling such voids, as well as for laying sloped roofs.

However, vermiculite has a lower thermal conductivity compared to other bulk materials and even mineral wool. This allows you to fill it with a thin layer, avoiding excessive stress on the supporting elements of the structure.

Loose insulating materials are also used for mixing into mortars for organizing floor screed and pouring over the ground.

Installation of non-combustible insulation is an obligatory stage of work when organizing a roof with a chimney. In the place where the pipe and its elements pass through the walls and roof, there must be a fire-resistant insulation that will not allow high temperatures to spread over the surface.

As a rule, for these purposes, basalt (for stainless steel pipes) or mineral wool (for brick chimneys) in the form of slabs is used. Such heaters have a higher level of heat capacity, they are tougher and more durable. In addition to sound and heat insulation, the material serves as fireproof insulation. Another insulation for the chimney is foam glass.

For water supply systems, air ducts, basalt slab insulation is also used, which protects pipes from freezing at low temperatures.

Tips & Tricks

- Despite the long service life of the foam glass, it should be protected from mechanical damage. Perlite also requires careful attitude, which quickly collapses even under insignificant loads, which leads to the loss of its technical properties.

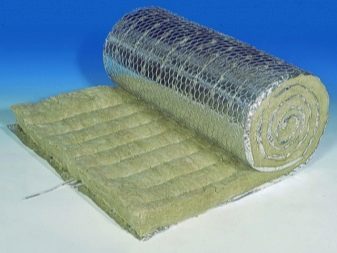

- If it is necessary to increase the thermal efficiency of mineral wool insulation, and there is no possibility of laying it in a thick layer, the purchase of basalt wool or glass wool with a foil layer would be an excellent solution.

- Standard rolls and sheets are equipped with a layer of foil on one side, which helps to reflect heat rays. This material, in addition to improved thermal insulation properties, is characterized by better water resistance, higher sound insulation qualities.

- To create a continuous heat-resistant barrier, foil-clad materials are additionally glued with metallized tape during installation.

- Bulk materials are poured over a vapor barrier film, and covered with a waterproof film on top.

For a test for fire safety of various heaters, see the following video.

The comment was sent successfully.