How to spray polyurethane foam yourself?

If you need to insulate various rooms from the basement to the attic, polyurethane foam will be an excellent solution. A material with outstanding properties, obtained by mixing polymeric substances, perfectly fits on all types of surfaces. With its help, even alone, you can produce high-quality insulation in houses at a reasonable price.

Peculiarities

The synthetic nature of the polymer allows you to modify its properties, improving them to indicators inaccessible to natural materials. In particular, polyurethane foam is an excellent insulation and has excellent adhesion properties to almost all types of surfaces encountered in the construction of thermal insulation.

Strong adhesion is provided with materials such as:

- wood - 1.5 kg / cm²;

- galvanized and cast iron - 2.0 kg / cm²;

- aluminum - 1.0 kg / cm²;

- stainless steel - 1.5 kg / cm²;

- cement - 2.5 kg / cm²;

- steel - 3 kg / cm².

In addition, the following are the positive features of the material:

- low thermal conductivity - 0.019–0.028 W / m²;

- lightness that does not affect the weight of structures - from 40 to 60 kg / m³;

- does not need fasteners - cost savings;

- protects coated metal from corrosive processes;

- there are no cold bridges;

- the ability to cover surfaces with any geometry;

- high durability, the material does not rot, does not dry out, does not collapse under the influence of atmospheric phenomena, temperature changes and other environmental phenomena, except for ultraviolet radiation;

- absolute safety, polyurethane foam is chemically and biologically inert, approved for use in food refrigerators;

- using a form with the required dimensions, you can create heat-insulating blocks of any format;

- the material is not interesting as food for rodents and insects, fungi and other microorganisms do not multiply on it, and it also prevents the growth of plant roots;

- resistant to aggressive substances: solvent, softener, fuel, mineral oil, dilute acid and alkali, foul gases of various origins;

- refers to hardly combustible substances, burns from the side of contact with direct fire and only if it is present, when it disappears, it goes out, the burned-out layer turns into coals and no longer supports combustion.

In addition to positive qualities, PPU has its own disadvantages, among which it is worth highlighting the following:

- the finished polyurethane foam layer is vulnerable to sunlight (ultraviolet). To compensate for this disadvantage, polyurethane foam is covered with paint or film with the necessary protective property;

- although PPU is slow-burning, but near a fire source, for example, a fireplace or a gas stove, it should not be used, even if it does not ignite, it may smolder or melt;

- relatively high cost.

Description

Polyurethane foam is a material related to gas-filled plastics with a cellular structure filled with air.

The liquid phase of polyurethane foam is formed due to the combination of two substances: isocyanate and polyol.

In 2–4 seconds after mixing the components, the polymer foams; when applied to the surface, a homogeneous mass with high heat-insulating properties is formed. Foaming is accompanied by an increase in temperature and an increase in viscosity, after which the material solidifies.

PPU is divided into two main types, such as:

- open-celled or soft polyurethane foam, which is used in light industry;

- closed-cell or rigid polyurethane foam, which is used in thermal insulation.

Composition

Closed-cell rigid polyurethane foam is formed by combining two components.

- Polyol (A) Is a hydroxyl substance that acts as a polymeric basis for polyurethane foam. It is weakly toxic and non-explosive, should be stored at temperatures from 0 ° C and above in a room with low humidity and good ventilation. Due to the tendency to delamination, component "A" must be mixed before use.

- Isocyanate (B) Is a mixture based on diphenylmethane diisocyanate (50 to 60%) and polyisocyanate. It has a high activity when it comes into contact with air, as a result, an unusable sediment is formed, which necessitates a sealed storage.

Specifications

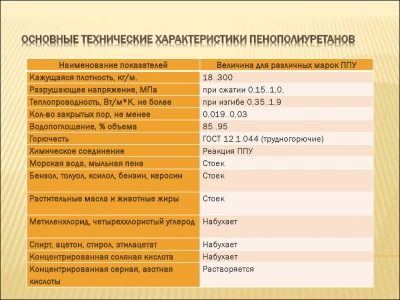

From a technical point of view, PPU has the following characteristics:

- The density is 18–300 kg / m³;

- Thermal conductivity - from 0.019 to 0.03 W / m²;

- breaking stress in compression - from 0.15 to 1 MPa, in bending - from 0.35 to 1.9 MPa;

- moisture absorption - from 1.2 to 2.1%;

- the number of closed pores - from 85 to 95%;

- flammability according to GOST 12.1.044 (hardly combustible substances).

Manufacturers overview

The quality of the components and the correct proportion are the most important conditions for obtaining a good polyurethane foam. In small stores, polyurethane foam cylinders with incomprehensible markings are often sold, the result of using which is the loss of money and the receipt of extremely unsatisfactory insulation. That is why it is recommended to choose trusted manufacturers whose products have only positive reviews from buyers.

- Yantai wanhua Is a large Chinese polyurethane foam company. She is one of the world leaders in the sale of polyurethane foam. The products are certified in accordance with all quality standards and at the same time have a reasonable price. By purchasing such a product, you can be sure of a guaranteed exchange in the presence of a factory defect. Product names: component A - Wanfoam-323C-1, component B - Wannate PM-200.

- Bayer Is a large German chemical and pharmaceutical concern with a worldwide reputation and an excellent reputation. Trade names of PU foam components: component A - Bayer Spray 150, component B - Desmodur 44V20 L.

- BASF Is a German chemical company with more than 150 years of experience, considered the world leader in the production of high quality PU foam components. The resulting insulation is characterized by a uniform structure, the components are mixed without any side complications. Product names: component A - Elastospray 1652 / 1-3, component B - IsoPMDI 92140.

How to calculate the expense?

When calculating the consumption of polyurethane foam components, several factors are paramount.

- The thickness of the applied layer. It is directly determined by the required level of thermal insulation and depends on the density of a particular polyurethane foam.

- Area to be treated (S). It is calculated according to the standard form S = l * h, where l is the length of the surface, and h is its height. The volume of the required polyurethane foam (V) is calculated from the formula V = S / p, where p is the flow rate per 1 m².

- Foamer used and type of work: pouring or spraying. It is generally assumed that the consumption of components A and B is 1: 1. In practice, when using a freon system, 1: 1 is consumed for spraying, and 1: 1.1 for pouring. When using a water system, 1: 1 is also consumed for spraying, and 1: 1.5 for pouring.

How to make it yourself?

There is a simple option to do it yourself. To do this, you need to buy one of the disposable kits. FoamKit from the American manufacturer is an excellent choice. With its help, you can single-handedly insulate a private house, cottage, attic of a cottage or other room. The disposable set consists of two small cylinders, which are supplied with a hose and a special gun with different nozzles.

After the start of use, the components remain usable for 30 days, and in the packed form - 12 months.

In general, the spraying process is as follows:

- you need to be located at such a distance that from the pistol to the wall is about 80 cm;

- the first thin sprayed layer is applied to ensure better adhesion to the wall;

- after 20 minutes, when it dries, the next layer is applied, which should not exceed 2.5 cm in thickness, and so on to the required thickness, with stops for the fresh layer to dry;

- on the final layer, excess and sagging is smoothed out 2–5 minutes after application. Homemade spraying is done.

When working, a number of the following conditions must be observed:

- the surface must be dry and free from dust and dirt;

- the temperature should not be lower than + 5 ° C, while depending on the humidity, the temperature of the working surface should exceed the dew point temperature by 3 degrees.

The alternative to self-production of the polyurethane foam components is very complex and requires a high level of knowledge in chemistry and, in addition, the manufacture of a high pressure unit, which will require advanced mechanical skills.

The use of disposable sets with spray nozzles is financially justified when working on areas not exceeding 30 square meters. m. And there are also many subtleties for determining the proportions for the desired result, non-specific surface and other nuances that must be taken into account even if there are factory components and equipment.

Components

In addition to the component cylinders, the disposable kit includes parts such as hoses, gun and nozzles. Professional equipment consists of many parts and is often a mobile unit like a gas welding machine.

High pressure sprayers include the following:

- "Foam-20" Is a product of a Russian company that can mix components in 11 different variations. The device is equipped with two 2.5 meter hoses, extendable up to 60 meters if necessary. It allows to produce 1-3 kg of polyurethane foam per minute, mixes in proportions from 1: 0.93 to 1: 1.7. The dimensions are 115x55x90 cm, and the weight is 110 kg.

- Reactor E-10 - This is an American installation for spraying polyurethane foam, polyurea, polyurethane, epoxies and others. It has compact dimensions 52x55x95 cm and a relatively small weight of 72 kg. It produces up to 5.4 kg of mix per minute, with hose lengths up to 32 m.

Recommendations for use

When performing work on the application of polyurethane foam, it is worth adhering to a number of prescriptions. With their help, you can improve the quality of the resulting surface, reduce the consumption of components, eliminate the need for reapplication due to flaking and other things.

It is not difficult to spray the material on the roofs if you follow the following expert recommendations:

- the sprayed material must be used with extreme caution;

- the surface on which the polyurethane foam is applied must be thoroughly cleaned and have a homogeneous structure. Dirt and dust, small debris, traces of oils and fats, easily falling off pieces of the surface must be removed from it;

- when working with a porous type of material, it is better to prime it before processing polyurethane foam to enhance adhesion;

- the humidity of the working surface should correspond to such indicators according to the base material as: concrete - 4% or less, cement-sand - 5% or less, wood - 12% or less;

- a wet surface must be blown with compressed air before application, and at temperatures below + 10 ° C - with warm compressed air;

- when mixing the components, their temperature and the temperature of the hoses must not be lower than + 20 ° C. If necessary, they must be placed in a room with a higher temperature for heating;

- component A must be thoroughly shaken before mixing, this can be achieved by rolling the container or turning on recirculation when using a spray apparatus with high pressure;

- the finished layer of polyurethane foam is vulnerable to ultraviolet light, after application it is better to cover it with paint or film with the necessary protective property;

- strong wind significantly affects the spray torch and work in such weather is not recommended due to excessive consumption of components;

- if crystals have formed in component B, it is recommended to heat it up to 65 ° C using a thermo-belt, heat gun or a similar method. Heating stops after complete dissolution of the hardened parts. The component must be cooled to operating temperature before mixing.

For information on how to independently spray polyurethane foam, see the next video.

The comment was sent successfully.