Knauf heaters: varieties and subtleties of application

Knauf heaters are the embodiment of the highest German quality and durability. The manufacturer produces mineral wool and polystyrene foam insulation for insulating various objects and sections of building structures.

Peculiarities

Knauf was founded by the Knauf brothers in Germany in 1932. Initially, the main activity was the production of gypsum plaster mixes. Over time, the assortment has become more and more diverse. In 1947, a plant for the production of gypsum building mixtures was opened in Bavaria, and in 1958 the production of gypsum plasterboards began.

Since the 70s, the company has significantly expanded the scope of its activities. First, cement-based building mixtures appear, then construction chemicals, then structural parts and heat-insulating materials based on polystyrene and mineral wool.

The products appeared on the domestic market in 1993, and after 10 years the first Knauf factories appeared in Russia. Today they can be found in St. Petersburg, Kungur, Chelyabinsk and other cities.

main parameters

It is logical to evaluate Knauf heaters according to the main criteria for all thermal insulation materials:

- Thermal conductivity... Depending on how much heat the material conducts, its thermal efficiency is determined. In other words, the insulation should have the lowest possible thermal conductivity. Products of the brand under consideration have a thermal conductivity in the range of 0.31 ÷ 0.42 W / m × C, which allows them to be considered effective heaters. So, a polystyrene foam plate 12 mm thick in its thermal insulation qualities can be compared with the thermal efficiency of a 450 mm thick brickwork or a concrete wall, the thickness of which is 2100 mm.

- Vapor permeability... The ability of the material to conduct moisture vapors, preventing them from transforming into drops of water and wetting walls or finishing materials. Indicators - in the range of 0.02 ÷ 0.03 mg / (m × h × Pa). Expanded polystyrene plates have the lowest rate, that is, they are, in fact, impermeable. In contrast, mineral wool is characterized by very good vapor permeability. This makes it the optimal (and almost the only) insulation for wooden surfaces.

- Moisture resistance... The best indicators of moisture resistance are polystyrene foam plates. They do not absorb moisture. Mineral wool heaters are afraid of water, therefore, when installing them, be sure to consider the presence of a waterproofing layer. The manufacturer uses a special technology - it processes mineral wool with hydrophobic compounds, which somewhat increases its moisture resistance. If we compare glass wool and basalt insulation, then the former is less resistant to moisture.

- Compressive strength, resistance to deformation... Both types of material are suitable for loaded surfaces, resistant to deformation. Mineral wool can be produced in rolls and placed in compact boxes, however, after being removed from them, it takes on its original shape, no creases are formed on its surface.

- Biostability... Expanded polystyrene in this respect loses to mineral wool - it attracts rodents.

- Fire resistance... Mineral wool is a non-combustible material, which cannot be said about expanded polystyrene.

Among other characteristics, durability (the service life of mineral wool - up to 50 years, expanded polystyrene plates - half as much), sound insulation qualities (mineral wool is also suitable for sound insulation), cost (stone wool has a higher cost).

The material has a different form of release (plates, mats, rolls for mineral wool, plates for expanded polystyrene), as well as various dimensions. Standard dimensions: slab width - 1000 mm, length - 1000-1200 mm, width - from 20 to 150 mm. The most popular are products with a thickness of 50 mm and 100 mm.

What are they made of?

The main types of insulation produced at Knauf factories are mineral wool and expanded polystyrene.

The basis of polystyrene foam materials is made up of air bubbles enclosed in a polystyrene foam base. Further, the material is extruded to improve performance.

Fiberglass is a strand of molten inorganic glass with the addition of sand, limestone, dolomite and other constituents.

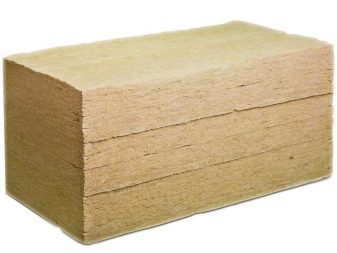

Stone wool is made up of fibers produced from rocks. They undergo high-temperature processing, after which threads are drawn from the semi-liquid raw material. They are formed into layers and additionally processed with hot steam, after which they are pressed.

Views

Depending on the material of manufacture, Knauf products are polystyrene foam and mineral wool. Mineral wool, in turn, is divided into basalt and glass.

If the classification is based on the form of product release, then roll, plate materials, and also mats are distinguished. It is convenient to lay mineral wool in a roll on horizontal surfaces... Plates, in comparison with mats, have greater elasticity and lower specific gravity.

Depending on the installation method, it is possible to distinguish between heaters that are glued to the base and those for which frame structures are provided for fixing.

Finally, depending on the area of operation, materials are divided into 2 large groups:

- for internal insulation;

- for outdoor insulation.

In each group, there is a more subtle differentiation - materials for walls, floors, ceilings. External insulation is facade insulation, insulation of the roof, basement, basement, interfloor ceilings. Accordingly, the facade needs a special insulation, the roofing material may also vary (for pitched, flat roofs, etc.).

Facade thermal insulation products are manufactured under ventilated and non-ventilated facades, under plaster or hinged systems.

Brand series

The most popular are the following series of Knauf products:

"Therm"

Expanded polystyrene insulation, which has a special treatment, thereby improving the technical properties of the material. It is distinguished by its versatility (suitable for thermal insulation of industrial and private facilities), can be used on loaded surfaces up to thermal insulation of road surfaces.

The material is based on expanded extruded polystyrene foam. The advantage of the material is a significant reduction in the toxicity of the product, which is achieved by replacing some hazardous components of the composition with completely safe (but more expensive) ones. The product contains no chlorine, phenolic and aldehyde compounds.

The thermal conductivity coefficient of the slabs ranges from 0.31 to 0.42 W / m × C, and the thermal conductivity - 0.02–0.03 mg / (m × h × Pa), water absorption - no more than 2%. The material is characterized by a wide operating temperature range.

Unlike the usual polystyrene foam insulation, it is a low-combustible, self-extinguishing heat insulator. Flammability class - G1-G3.

Depending on the scope of application, the following are distinguished subspecies "Heat Knauf" - "Roof" (material for insulation of roofs, attic and interfloor floors). Slabs marked as "Roof" are used for insulating flat roofs, "Roof NL" optimal for pitched structures, "Roof Light" suitable for thermal insulation of ceilings from inside the premises.

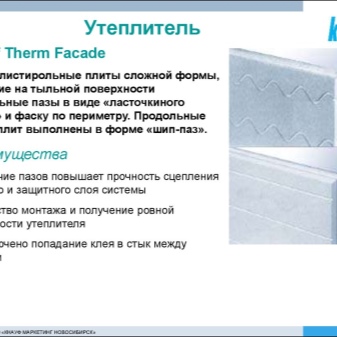

Slabs are produced for thermal insulation of walls Knauf Therm Wall, for facades - Knauf Therm Facade (suitable for external thermal insulation of walls, for different types of facades), for floors - Knauf Therm Floor (they can withstand high compressive loads, therefore they are used not only for insulating floors, but also for floor surfaces in garages, can be used directly under a concrete screed).

It should be noted that the manufacturer produces a wide range of floor insulation boards. If the room does not provide for a large load on the floor, then you can save money by purchasing Knauf Therm Concrete.

There is a special modification for the underfloor heating system - "Knauf Therm Underfloor heating"... These slabs have a special relief, between the protruding parts of which pipes are placed to organize a warm floor.

Knauf Therm Compack - This is a type of slabs that is not intended for heavy loads, but has a higher vapor permeability, which makes it possible to use the material for internal insulation of premises.

Plates of increased strength have completely opposite characteristics. Knauf Therm Perimeter 5 in 1, which, moreover, are distinguished by their versatility of use - they are suitable for foundations, floors, walls. These boards have the highest technical performance among all other products of the manufacturer.

The improved strength indicators are due to the production technology - the material is immediately given the required dimensions before pressing, it is not cut from finished sheets. This, in turn, avoids damaged granules.

For ease of installation, the material has a stepped edge, due to which a sealed monolithic surface is formed.

"TeploKnauf"

Mineral wool insulation for private houses. It is produced in 2 modifications - glass wool and basalt analogue. Depending on the density, it can be used on different parts of the house. The materials are adapted for use in residential premises and have elasticity.

The following modifications are distinguished:

- "TeploKnauf House" - a universal insulation for private houses in which year-round living is provided. Available in 2 versions - 50 and 100 mm thick.

- "TeploKnauf Cottage" - insulation, which implements the "three in one" approach. It simultaneously protects the house from noise, prevents heat loss and has increased moisture resistance. It is produced in rolls and plates, the thickness of which is 50 mm. There is also a version of "Cottage +" with a material thickness of 100 mm. Suitable for curtain walls and contact finishing (eg Grünband plaster).

- "TeploKnauf Dacha" - insulation for summer cottages, temporary buildings, summer kitchens and other objects characterized by seasonal (only in the warm season) operation. Release form - rolls 50 mm thick.

In addition, there is an option for roof insulation (it has increased moisture-resistant characteristics), a material for floors.

There is a special series "Ecoroll" with increased vapor permeability for thermal insulation of wooden living quarters.

Knauf Insulation

The Insulation modification (formerly Knauf Expert Heat) is a stone fiber insulation designed for professional use. It differs in density, therefore, for each section of the construction object, it is possible to find the optimal type of material.

A feature of the products is increased strength and durability. Release form - plates and rolls.

There are several modifications of this professional basalt fiber:

- "Knauf Facade" - available in 2 forms ("Thermo Plate 032" and "Thermo Plate 034") suitable for ventilated facades, as well as a component of sandwich panels.

- "Knauf Thermo Roll 040" - insulation in rolls for interfloor and attic floors, floors and all horizontal surfaces that do not provide for a load on the heat insulator.

- "Acoustic" - material in the form of slabs and rolls with increased sound insulation characteristics.

- "Pitched roof" - slabs and rolls for pitched slabs and attic floors.

- "Knauf NTV" - a material with a foil or fiberglass coating is used in the organization of ventilated facades, for thermal insulation of industrial installations.

- Knauf LMF AluR - mats with a foil layer, due to the design features, can be laid on uneven surfaces.

- "Knauf FKD" - slabs of increased rigidity, having a reinforcing fiberglass mesh on the outside. They are used as facade insulation for plastering, as well as for sound insulation and fire protection.

- Knauf WM 640/660 GG - rolled insulation for industrial use, with reinforcement in the form of a galvanized mesh on one of the sides.

Advantages and disadvantages

The advantage of the material is its low thermal conductivity coefficient.

If we talk about expanded polystyrene plates, then they have good moisture resistance. Since the insulation does not absorb moisture, it is the best option for thermal insulation of the foundation and plinth, as well as other areas of objects.

The wide scope of application is due to the low weight of the materials, so they do not exert a high load on the supporting structures of buildings. In addition, the light weight of the materials means lower shipping costs.

Expanded polystyrene plates and mineral wool insulation of high rigidity have mechanical strength, therefore, they are suitable for thermal insulation of loaded structures.

The downside is the flammability of the polystyrene-based material. Despite the presence of special fire protection treatment, it still belongs to combustible materials... And if we talk about mineral wool insulation, then their strong point, on the contrary, is fire resistance. The melting temperature of stone wool is about 1000 degrees, glass wool - 500 degrees. This allows you to assign materials to the class NG (non-combustible). Another plus - when temperatures rise, mineral wool does not emit toxic components, which cannot be said about expanded polystyrene.

Undoubtedly, the manufacturer managed to improve in many ways the technical characteristics of expanded polystyrene boards, but the material still has low vapor permeability, chemically unstable, unable to resist UV rays and attracts rodents. Finally, if in addition to insulation, soundproofing functions are important for the user, then it is worth purchasing another material, for example, mineral wool.

The naturalness of the components of mineral wool insulation ensures their environmental friendliness. In terms of its thermal insulation qualities, it is not inferior to polystyrene foam plates. User reviews allow us to conclude that the popularity of stone wool, despite its higher cost, is due to the combination of high heat and sound insulation characteristics, biostability, and durability in one material.

Of the minuses, one can single out less moisture resistance, which requires the organization of waterproofing, the need to use a respirator and workwear (fibers irritate the mucous membranes of the upper respiratory tract, and glass wool penetrates the skin).

Usage Tips

When insulating a private house and a cottage, it is recommended to combine specialized materials with products of the same series for roofs and ceilings.

When choosing a material, it is important to consider the scope of its application. The thickness of the material will depend on the region of operation, the required thickness of thermal insulation, wall material and finishing materials.

For an overview of Knauf insulation, see the next video.

The comment was sent successfully.