Thermal insulation K-Flex: an overview of the products of the Italian brand

Today the construction market is replete with insulation. They have different specifications based primarily on the application. The features and purpose of K-Flex insulation will be discussed below.

What it is?

Thermal insulation or insulation is a material used to increase the thermal efficiency of an object. This effect is due to the low coefficient of heat loss of the material, due to which the thermal resistance of the structure increases. It is possible to insulate both civil and industrial construction objects, as well as communication systems, equipment, engineering structures. If we talk about the thermal insulation of pipelines, then it provides the effect of a thermos - it prevents cooling or heating of the contents, the formation of condensation.

Features and Benefits

The full name of the company is LK Isolante K-Flex. This Italian brand has more than 12 years of history and occupies a leading position in the world market among other reputable insulation companies. The main share of production is made up of foam materials intended for thermal insulation of pipelines and various communication systems. The high demand for products leads to an increase in the company's power. About 10 K-Flex factories operate in different countries, including Russia.

Thermal insulation material K-Flex is characterized by low thermal conductivity, long service life, weather resistance and resistance to temperature extremes and corrosion. Heaters are moisture resistant, environmentally friendly.

It is also convenient that they are easily and quickly mounted, without requiring an additional vapor barrier layer or the use of additional fasteners. The products are optimal for pipes of complex configuration with many bends, which is due to the elasticity of the material in combination with its high tensile strength.

Materials perform not only a heat-insulating function, but also a decorative one. Due to its versatile, attractive appearance, hydrophobicity of the coating and its resistance to aggressive elements, the insulation can be used in solving those problems where the aesthetic component is important.

Appointment

Scope of application - thermal insulation of heat carrier pipes and engineering structures. The temperature of the contents of tanks and pipes can be positive and negative - thermal insulation will ensure that the set temperatures are maintained. K-Flex products can also be used underground, withstanding appropriate loads, groundwater and soil freezing.

K-Flex products have a wide range of applications and are suitable for use in the following areas:

- as a heat-insulating and protective material for air ducts and air conditioning systems;

- insulation of pipeline and sewerage systems, heating networks;

- isolation of valves;

- oil industry - platform insulation;

- shipbuilding;

- public transport;

- thermal insulation of pipes of refrigeration units and laboratory equipment.

Specifications

- One of the most important technical characteristics of K-Flex heaters is, of course, their low thermal conductivity, which is 0.034–0.049 W / m · K.This is achieved through an optimal, precisely adjusted ratio of small cell volume to material weight.

- The thermal insulation material of this brand does not accumulate moisture, resists direct exposure to liquids. In terms of its vapor permeability, it can be compared with that of a polyethylene film. The latter, as you know, is used as a vapor barrier when insulating various objects. The vapor permeability indicators of the insulation are 0.003–0.006 mg / (m · h · Pa).

- High rates of vapor permeabilityand the hydrophobicity of the material guarantee the protection of the insulation and work surfaces from freezing, condensation, and oxidation of metal elements.

- Products are not afraid of direct UV rays, precipitation, withstand high and low temperatures in the range from -200 to + 180 ° C, as well as sharp temperature drops. The density of the material depends on its type, in general it ranges from 65 to 80 kg / m³. Although there are series where the density reaches 75 and 130 kg / m³. The material is characterized by chemical resistance - it does not deteriorate under the influence of chemicals, technical fluids, petrochemical products and even volatile compounds.

- Insulation does not support combustion (flammability class - G1), and does not emit toxic elements when the temperature rises. This is the merit of the fire retardants included in the composition. Due to this, the insulation is successfully used in points with an increased level of fire hazard. Absolute environmental safety, confirmed by a certificate of conformity of an international standard, allows the use of the material at facilities that are subject to increased sanitary and hygienic requirements. First of all, these are medical and children's institutions, various laboratories, pharmaceutical and food enterprises.

- The material (even when cut) does not emit toxins, dust, the smallest particlesnegatively affecting the condition of people and animals. It does not have an unpleasant smell, and its production and operation do not harm the ozone layer of the planet. The manufacturer gives a 20-year warranty period for its products. Insulation has various forms of release and sizes, which expands the scope and simplifies installation.

Composition

K-Flex products are extruded foamed rubber insulation materials that are further foamed. OAgain, the composition is nitrile-acrylic butadiene rubber of synthetic origin. It is he who provides the flexibility of the material. Additional components of the composition are polymers, fire retardants, minerals, which provide certain operational characteristics of the insulation.

The raw material is pressed through a die and then vulcanized.

Technological processes are regularly improved, which allows the manufacturer to produce products of the highest quality and periodically supplement the assortment.

Series and types

Depending on the scope of application and the expected technical characteristics, buyers can choose one or another series of K-Flex insulation.

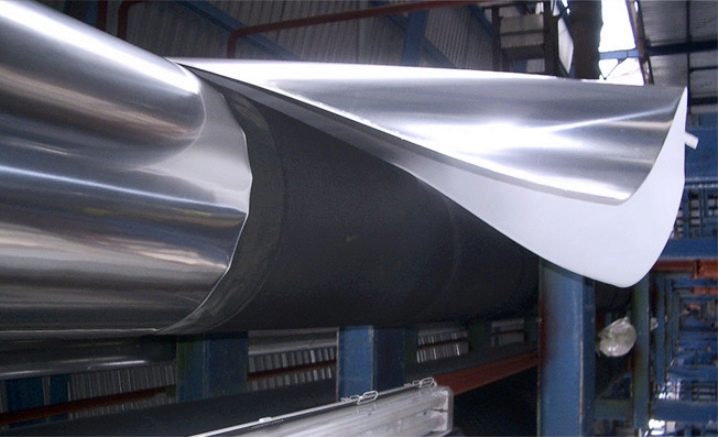

- K-Flex ST. The rubber base has a three-layer aluminum foil coating on one side and a two-layer PET foil protection. The material is used for insulation of heat carriers, engineering systems, including those operated in refrigeration and cryogenic conditions. Due to the peculiarities of the composition, it not only provides thermal protection, but also prevents condensation. The operating temperature range is from -200 to + 105 ° C, the material is optimal for use in cryo-installations, but not suitable for all heat carriers.

- Solar HT it is suitable for insulating heat carriers, pipes and systems of complex shapes, since it is characterized by improved flexibility. It is distinguished by the maximum indicators of resistance to heat (up to + 180 ° C), vapor permeability (Flexy Fiber technology).

- K-Flex Air. This series is designed for the insulation of air ducts in ventilation shafts and air conditioning systems. The operating temperature ranges from -30 to + 80 ° C.

- K-Flex Eco It is used in areas where there are more stringent requirements for the environmental safety of insulation (pharmaceuticals, metro, airports). A distinctive feature is resistance to microorganisms, as well as a greenish tint of the material. Operation is possible at temperatures from -70 to + 130 ° C, short-term heating up to + 150 ° C is allowed.

- Al Clad. The main purpose is to protect industrial pipes and engineering systems. It is distinguished by increased resistance to aggressive media, including technical fluids, petrochemical products, mechanical damage, temperature "jumps".

- K-Flex Igo. This material is distinguished by a fine-mesh structure with closed pores, which ensures that the working bases are protected from the penetration of vapors. This property allows the material to be used for thermal insulation of underground and above-ground piping systems and welds.

- K-Flex ST / SK - This is a fairly universal insulation, suitable for insulating pipes of various functionality, elements of air conditioning systems. For fixing, special glue is required.

All of the listed materials can be produced in their original form or have a protective coating. The latter is of the following types:

- Alu - this is a protective coating, which is a "cake" of three layers of aluminum foil with a thickness of 9 microns, between which layers of transparent polymer are laid;

- Al clad - it is a self-adhesive protective coating consisting of foil, polypropylene and polyethylene film;

- In clad - this is a polymer layer that protects the entire surface of the pipe from the effects of water, petrochemical products;

- Ic Clad BK - This is a protective coating, which is a fiberglass, which increases the strength and durability of the insulation.

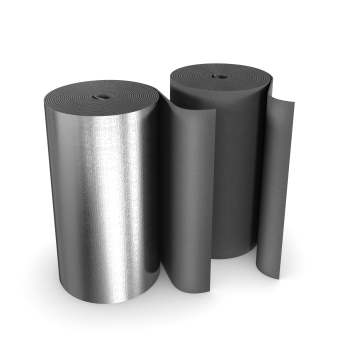

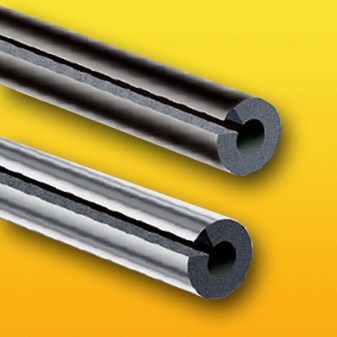

Depending on the form of release, materials are of the following types:

- hollow tubes with a diameter of 6–160 mm and a wall thickness of 6–32 mm;

- shaped products (tee, corner) for thermal insulation of joints and pipe bends;

- sheet products in the form of layers with dimensions 1x2 or 0.5x2 m for a wide range of applications (Air series);

- roll thermal insulation with a width of 1 m (less often 1.5 m), and also characterized by its versatility of use;

- self-adhesive tape 3 mm thick and 1.5, 5 or 10 cm wide, the outer layer has a polyethylsiloxane coating or polyvinyl mesh;

- two-segment pipe hanger with PVC reinforcement as an outer layer.

Additional components

K-Flex thermal insulation is characterized by the fact that it requires minimal use of additional fasteners. You will need glue to fix the material. It can have several varieties, for each type of pipes its own version is presented. The most common are one-component formulations based on polychloroprene rubber and its two-component analogue based on a rubber solvent.

If the object to be insulated is outdoors, it is recommended to use a special joint sealant.

Installation guide

Heat-insulating works can be carried out at a temperature not lower than + 5 ° С. The work surface must be clean and free from grease. Only if these conditions are met, it is possible to guarantee the high-quality adhesion of the insulation.

The installation process begins with the application of glue to the pipe surface and the inside of the heat insulator. After that, you should wait 2-3 minutes for the adhesive to penetrate into the layers of the material. For self-adhesive products, this step is skipped. Insulation is applied to the pipe in such a way that the seam goes to its lower part. After that, the surface to be pasted is smoothed out with a slight pressure.

Tips & Tricks

If the glue for fixing the insulation to the pipes has thickened, then it can be diluted with a cleaner of the same brand, mix the mixture thoroughly.If cylindrical tubes are purchased for thermal insulation of pipes, then they are pre-cut along.

For K-Flex insulation, see the following video:

The comment was sent successfully.