Corrugation for the toilet: purpose, types and installation tips

Sometimes, only with the help of corrugation, you can install the toilet in the desired position. When using standard rigid pipes, this is not always possible in the position that the owner wants. The article will discuss in detail all the issues related to the use of plastic corrugations to dismantle an old or install a new pipe.

Features and purpose

A free-flow toilet cuff made of plastic makes toilet repairs much easier. Previously, in order to connect the toilet structure to the sewage system, cast iron pipes were used, which were distinguished by their severity and difficulty in installation. Currently, it is much easier and more convenient to use plastic products for these purposes. And even in the conditions of many apartments, when every square centimeter counts, such a toilet corrugation is the only possible way out in order to install a urinal.

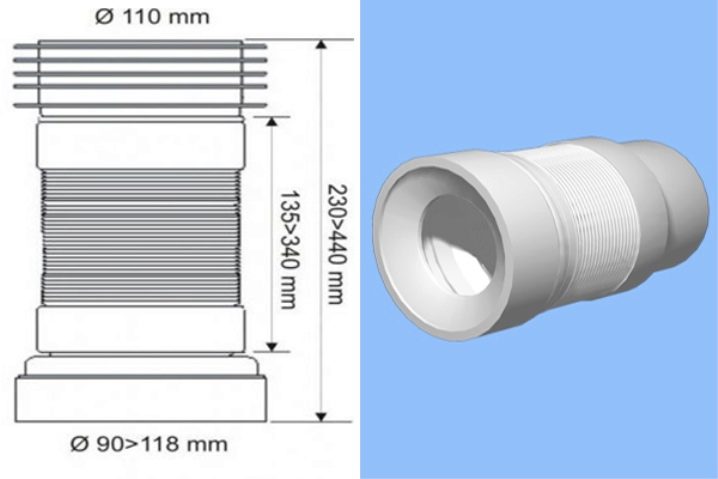

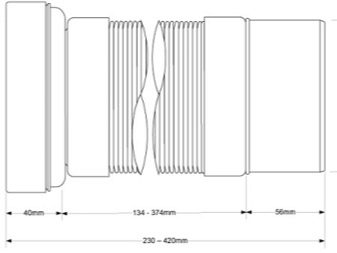

Corrugation is called the transition element of the plumbing system., which is designed to connect the toilet pipe to the sewer pipe. It is a wide corrugated tube made of thermal plastic. Its edge is a connecting sleeve, which makes it easier to connect the pipe and the toilet outlet. The length of the corrugation is on average 25-30 cm, the cuff has a diameter of 13.4 cm on the outside, 7.5 cm on the inside (from the side of the toilet). The end that is connected to the sewer pipe has a diameter of 11 cm.

The peculiarity of the toilet plastic corrugation is that there is a layer inside it that significantly increases its technical characteristics. This is especially noticeable if you choose the products of the world's leading manufacturers, such as SML or Duker.

Installing a corrugation on the toilet is much more convenient and profitable than a cast-iron pipe. Firstly, plastic is lightweight, costs less, and has a much longer service life.

It's easy to clean, you can do it yourself. Before installing the corrugation, no preliminary embossing is required.

Corrugation is not always used. In most cases, it is preferable to take a plastic pipe, it is much stronger.

Toilet corrugation is used in a number of cases.

- In a situation where the toilet is axially offset relative to the sewer socket. This can happen when the floor level rises due to the tiles being laid on the floor, or when the owner decides to move the toilet to a different location. In each such case, there will be no exact joining of the toilet outlet and the sewer socket, that is, you will need to use a special corrugated drain. If the toilet is replaced and a new one is installed in another place, the corrugation should be at least 50 cm. If you do not use plastic, you will have to move the sewer pipe. If, at the end of the repair, the floor in the bathroom rises (and, accordingly, the toilet bowl rises), replacement of the corrugation is not required.

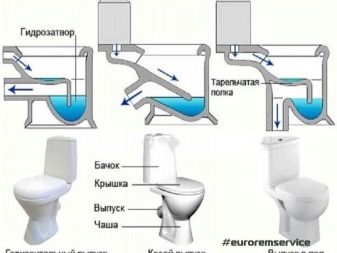

- Another situation is when the release itself is atypical. The toilet can be designed in such a way that the type of existing sewer does not match the outlet. For example, sometimes modern plumbing is required to be installed in an old-style apartment. In it, the release is usually direct, and in obsolete toilet bowls, it is oblique.

Therefore, in the case when the equipment has a horizontal or vertical outlet, in order to connect it, you will need to use a corrugated pipe that can be bent at the desired angle.

Advantages and disadvantages

The advantages of plastic corrugation are many, and they are quite significant:

- Ease of installation - it is quite possible for a person without special knowledge to cope with replacing a pipe.

- Budget is perhaps the main advantage along with ease of installation.

- The only option available in case of moving or sliding the toilet.

- In the event of a mismatch between the outlet on the toilet and the sewer socket, only plastic can be installed.

- Suitable for a temporary toilet, installed before the end of the repair.

Along with many advantages, there are also disadvantages.

- The fragility of the structure due to the small thickness of the pipe walls. If you drop something with sharp edges into the toilet, for example, a shard of ceramic tile or glass, the corrugated pipe may be damaged and it will have to be replaced.

- If the corrugation is placed at the wrong angle or given the wrong bend, it can easily become clogged.

- If the corrugated tube is too long, it can sag under the weight of the contents.

- The corrugation cannot be placed in the wall, only outside.

- According to many users, the design has an unattractive and bulky appearance.

Types and sizes

Toilet corrugations can have these parameters.

- Elasticity. Depending on it, they are soft and hard. The latter have higher strength and wear resistance. The soft corrugation can be installed on a toilet bowl of any configuration and with any type of outlet (vertical, oblique or horizontal). The more flexible the pipe, the easier it is to install.

- Reinforcement. With its help, plastic pipes are strengthened. For this, steel wire is used. Reinforced reinforcement lasts longer, but it also costs much more.

- The length of the corrugated pipes also differ. On average, the range varies from 0.2 to 0.5 m. When purchasing fittings, you need to take into account the distance from the toilet bowl to the place where the corrugation cuts into the pipe. It is best to always buy a slightly longer channel, about 5 cm larger than required. This makes it easier to avoid leakage.

The diameter of the corrugation can be 50, 100, 200 mm. Before buying, you need to measure the diameter of the toilet bowl opening, and, based on the figure obtained, purchase a pipe with the appropriate section. You can buy it at any store of building and finishing materials.

A cuff is a plumbing part that is responsible for ensuring a tight connection between the toilet and the sewer outlet. It is a must for every floor-standing toilet. Therefore, when purchasing plumbing, you should also buy a cuff in the kit.

The models presented in stores are different in many ways: material from which they are made, diameter, shape. The standard cuff diameter is 110 mm, but there may be other options. It is necessary to find out what type of outlet the toilet is equipped with, and what its diameter is, because it is on it that the cuff will be attached with the second end.

If the dimensions do not match, then it is necessary to purchase a simple cone model (if the connection is direct), or a combined one with different output dimensions (if the connection is offset).

If you classify cuffs, the following varieties can be distinguished:

- straight smooth;

- corner smooth;

- conical;

- eccentric;

- corrugated.

There are also combined models: they are straight and smooth at one end, and corrugated at the other.

The funnel is suitable for connecting toilets with horizontal or oblique outlet. It is installed in a 90 mm pipe (cuffless) or in a pipe with a cut of 110 m.

The eccentric cuff consists of two cylindrical surfaces connected together, but shifted relative to each other along the longitudinal axes. The standard diameter of the seamless outlet pipe is 72 mm.

According to the material from which they are made, the cuffs are divided into rubber and plastic. If the toilet model is modern, and the pipes are made of plastic, then polymer types are used. And for a joint with a cast-iron pipe, traditional dense rubber is suitable.

Be sure to consider the shape of the toilet outlet. She may be:

- vertical;

- horizontal;

- oblique.

The clutch is an obligatory part. Models for plastic pipes are produced in limited quantities - only five types:

- Pipe / pipe - products with smooth walls are fixed relative to each other by a thread. Used for rigid plastic pipes, put on both ends in turn.

- Box / Pipe - The pipe contains the cable on one side and the compression clamp on the other.

- Fitting with detachable connection.

- The transparent pipe is suitable for soft joints of the corrugated pipe, it is strengthened by means of winding.

If you don't want to be bothered by unpleasant odors, you can equip the toilet with a check valve. It can be installed not only in the toilet, but also in other plumbing items that have an outlet to the sewer.

The check valve protects each of the plumbing items from blockages, and eliminates odors, preventing them from spreading throughout the living space. This is true both for residents on the upper floors and on the lower ones.

How to choose?

Each product can be attributed to its type, guided by a combination of parameters such as:

- length and diameter;

- reinforcement;

- elasticity.

You can choose the right product based on the required parameters, as well as being guided by the requirements for quality and strength.

It is advisable to buy a certified product, and also carefully study the marking on it before purchasing. There is no need to be tempted to buy a suspiciously cheap product, because, as you know, “a cheapskate pays twice,” and it is highly likely that, having installed a penny corrugation, you will soon have to go to the store for a new one.

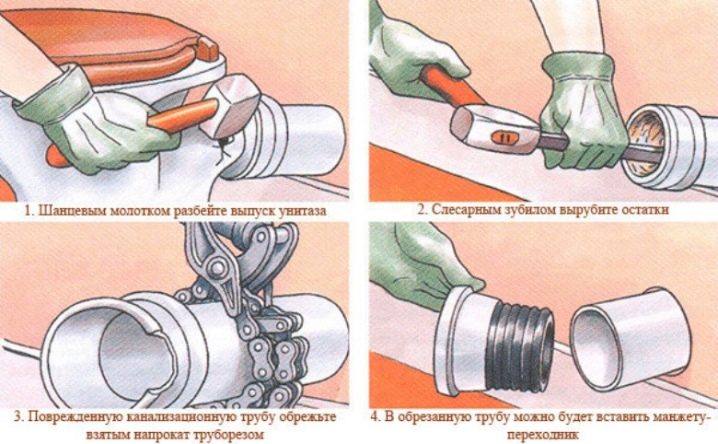

Dismantling the old

To replace the corrugation on the toilet yourself, you need to dismantle the old pipe. This is a stepwise procedure that requires a certain sequence of actions.

To do this correctly with your own hands, you need to prepare several buckets and unnecessary rags. First you need to turn off the water supply to the drain. Then you need to unscrew the pipe that lets the water through. After that, the water is drained from the tank, and then you need to remove the tank.

The dismantling process begins with the toilet. If it has been installed and operated for a long time, then, most likely, it is very firmly fixed in the cement. It is impossible to pull it out without damage. In this case, you need to hit the toilet with a hammer. From vibration, the impact on the cement base will increase, so the dismantling process will go easier.

In no case should you hit a pipe, especially a cast iron one, as there is a risk of a crack or even its complete destruction. A crack in the corrugation cannot be repaired, and to install a new one, you will have to completely replace the pipe. This will entail additional costs and time.

When the neck is broken, the structure can be dismantled. First you need to rock it. If this does not work, using a hammer and chisel, you can try to knock down the base from the cement. Often after that, the toilet cracks or falls apart, they need to be disassembled. To prevent the toilet from being flooded with water, cover the structure with rags.

After the toilet is dismantled, you need to knock off all the fragments and remnants of cement from it. As soon as its lower cut becomes even, you need to clean the socket and remove the pieces of the toilet bowl from it. As soon as the channel is cleaned, it must be plugged, otherwise the unpleasant smell will spread throughout the house. After that, you can change the corrugated pipe.

How to install?

In order to change the corrugation, you will need the following tools:

- hammer;

- sledgehammer;

- roulette;

- glue "liquid nails";

- fum tape;

- keys;

- hose to drain the water.

This is very easy to do.First you need to try on the pipe; for this, the corrugation is applied to the place where it is planned to connect it. It will immediately be seen whether the neck of the toilet bowl, the drain pipe and the corrugation itself are joined. You can immediately determine whether the length of the corrugated pipe is suitable.

If necessary, the corrugation is cut off and the markings are made. The points where the dowels will be should be marked with a marker. The base for the toilet also needs to be marked. A cistern and a drain pipe are installed on the toilet. Using a puncher, you need to make holes for the dowels, after which the installation of a new corrugated pipe begins.

First, wipe it with a dry cloth, then apply sealant to the gasket. Then the pipe is inserted into the sewer hole. On the other hand, the pipe also needs to be treated with a sealant, after which the treated channel should be put on the toilet in the neck area. Sealed cracks and crevices should be repaired with the same sealant or liquid nail glue.

In the place reserved for the base of the toilet, you need to put a rubber gasket, after which you need to apply silicone sealant to its circumference. Now you can put the toilet in and secure it.

As soon as the glue has "set", you need to check the quality of the structure. To do this, flush the water in the toilet and check if it is leaking from under it.

In addition to this method, you can heat the corrugated pipe. It is exposed to high temperatures until the end is soft. Then you need to immediately put on the corrugation on the toilet drain. Next, the second end of the sewer bell is joined to the corrugation and a sealant is applied. The connection is now complete.

You can connect a toilet with a direct outlet to a sewer with an oblique socket using a plastic corner. Modern stores offer a wide range of products from this material. To prevent water leakage from under the toilet, you need to use, in addition to the corner, a rubber seal.

See below for a master class on installing corrugations.

Helpful hints

When purchasing, experts recommend taking into account the length of the corrugation. This is especially important for those bathrooms or toilets in which the toilet bowl moves away from the wall quite far. The corrugated pipe can be pulled out, but this action has certain limitations. And the more you expose it to stretching, the thinner its walls will become, which has an extremely negative effect on its strength.

It is undesirable to pull out the fittings before mounting on the toilet. Only when docked with the sewer can it be stretched. If you do not follow this advice, the structure can sag, and this is fraught with the formation of a blockage in the system.

You can shorten the corrugation after measuring the desired length, but even then you should not cut it exactly to this distance. You need to leave a small margin of length.

When installing a corrugated pipe, it is important that the channel is curved without interfering with the water flowing out unhindered. It is impossible to pinch the pipe, otherwise damage is possible, and in the future it will begin to leak.

It should not be forgotten that corrugation is a fragile product and is not designed for excessive stress. Nothing should press on it from above or from the side.

The pipe is leaking

If a malfunction is found in the plumbing, this becomes the source of many problems. Untimely elimination of the breakdown can lead to both the spillage of sewage in the apartment, and flooding of the neighbors with water from below. Given that the odor emanating from the contents of the current toilet is incredibly durable and absorbing into furnishings, walls, floors and ceilings, it is imperative to deal with leaks as quickly as possible.

Often the reason that the toilet is leaking can be a corrugated pipe, which is either incorrectly installed. It can also be of poor quality initially.

The corrugation looks like an accordion connecting the toilet outlet to the drain. To make sure that it is the corrugated pipe that flows, you need to drain all the water from the toilet and see where the leak has formed.

If confirmation is received, then the pipe must be either repaired or replaced. Before proceeding with the repair, you should find the place of the leak.

There can be two options:

- the pipe burst or cracked;

- a leak has formed at the junction with the sewer or toilet drain.

Corrugation is repaired in this way:

- The crack must be dried (using a hair dryer), and then sealed with a rubber patch. The glue should only be waterproof.

- Saturate a piece of clean rag with epoxy and wrap it around the hole. Previously, the place of repair must be degreased.

- Saturate the bandage with a cement mixture, then slide the resulting structure onto the pipe.

- Cover the bandage with sanitary silicone and wrap the toilet outlet with it.

It is important to note that all these methods will be able to eliminate the leaky docking only temporarily. After all, it is impossible to repair the corrugation and make it waterproof again. It is best to purchase a new pipe and rearrange it.

Why is there a leak?

This happens especially often when purchasing cheap equipment. The corrugation of questionable quality does not fit tightly enough to the pipe (its inner surface), and unwanted folds form on it. The appearance of a leak in this case is a matter of time.

Also, in some low-quality types of corrugated pipes, the skirt on the cuff is not straight, but conical. It shouldn't be. More expensive models, especially those made by leading companies in the market, have better quality and durability.

To carry out high-quality repairs, it is advisable to seek help from specialists. At the same time, you should not leave the plumbers without attention, it is better to follow what they are doing.

As for the materials, it is better to purchase them yourself, since very often called specialists try to save on corrugation, and this will inevitably entail new leaks.

A blockage has formed

Such an unpleasant thing as a blockage in the sewer is known to the vast majority of home owners. This is especially true for apartments where old pipes are installed, and the sewer system is used incorrectly. The appearance of blockages is caused by the ingress of hair, dirt, grease into the pipe, as well as undissolved detergents - shampoos, lotions, balms, soaps and others.

It is best to first try unclogging the toilet using a plunger. It is necessary to install it as tightly as possible to the drain and press it several times. This method is effective if the blockage is small and the particles are small.

If everything is not so simple, and the size of the cork is large enough, and it itself is covered with a layer of fat, then the plunger is useless. You can use a chemical to clean the drain. There are currently quite a few such products in the respective stores. They usually contain acids and alkalis, which dissolve blockages in the pipe.

Such a tool is simply poured into the pipe. To dissolve the cork, you need to wait at least 4-5 hours. After that, hot water is poured into the pipe. It is best to do this at night, since it is at this time that the plumbing is least used, and the product will have enough time to clear the blockage.

You can use a mixture of baking soda and vinegar (for 1 pack you need to take 1 bottle). The effect of such a mixture will be similar to a chemical agent. After using both ready-made and self-made solution, you must also apply a plunger.

All of these methods are good for removing fresh blockages. If fossils are formed in old pipes, they are unlikely to help. Then a metal cable can come in handy. It is placed in a pipe and rotated, gradually moving inward. This can help with fatty or hair blockages, but if, for example, spoiled pickles have been poured into the toilet, or a sanitary napkin has been thrown away, the cable is also powerless.

If you can't get rid of the blockage, it is better to ask professionals for help. You need to call the housing department and leave a request.There are also paid services that tend to be more responsive and have all the tools you need to troubleshoot problems with them. In difficult cases, blockages are cleared using special hydropneumatic impulse equipment.

It is important to remember that removing a blockage is more difficult than preventing it. It is necessary to promptly clean with a chemical agent at least once a month, and also try to prevent hair, grease, soap and large objects from getting into the pipes.

The comment was sent successfully.