Toilet cistern: choosing the perfect device

The toilet cistern is perhaps the most problematic element among all plumbing equipment. It quite often fails, disrupting the functionality of the entire bathroom, in addition, for certain plumbing fixtures you need to choose your own type of this fixture, and design plays an important role. Therefore, it is worth learning in more detail how to choose the perfect toilet cistern device.

Peculiarities

The main functional element of the toilet bowl - the cistern - despite the many modifications and different designs, has remained unchanged in its operating principle for more than 150 years. This is a container, most often made of ceramic, containing a manually operated mechanical device. Its function is to provide an intense flow for a quick flush, which forms a water plug and "blocks" odors. A toilet tank is connected to the water supply through a hose system, a container of a certain volume is needed to accumulate a volume of water sufficient for flushing.

In general, toilet cisterns have 2-3 technological holes for supplying and draining water. Inside, the flushing tanks have mechanisms for shutting off the liquid when it fills the required volume, and for flushing it into the bowl. Draining is carried out by gravity.

Toilet cisterns can be separate or compact. In addition, there are options for a monoblock, where the water tank and toilet bowl are made in a single inseparable body.

Views

Almost all domestic old-style toilets had a separate flush cistern. This means that it is separated from the bowl and suspended at a height, and a pipe is used to supply water downward. The advantages of this design are that the pressure is very strong, therefore, the higher the container is, the more intense the flush. The mechanism for flushing the cistern, located separately, is simpler, it occurs with the help of a rope. But many people find such a design with a tank suspended from the ceiling not very aesthetic and presentable.

Unlike separate devices with a hinged cistern, the compact type has a water storage tank located directly on the toilet - in its back part behind the bowl. It is believed that this is a newer type of plumbing, although it was invented over a century ago. Such toilets have a more aesthetic appearance and take up less space. There is no need to hang a bulky and heavy container at a height; instead, toilet shelves can be placed above the toilet in full height to the ceiling. Cisterns of the compact type are most often made with a button, with the help of which the flush is carried out, less often models with a lever are presented.

Monoblock is a single, inseparable structure of the toilet and cistern, the latter is located above the bowl at the back. Such a model is cast directly in the production from ceramics, metal or plastic. It is impossible to disassemble the fragments, this complicates transportation and makes the plumbing more cumbersome. But there are also advantages: the monoblock is more hygienic - there are no joints between the tank and the bowl, dirt and rust do not accumulate under them and the rubber seal. The monolithic construction also looks more stylish and harmonious.

The monoblock can be floor-standing or hanging. The latter design is more difficult to install, because it is required to install the entire system so that it can withstand the weight of a seated person.But on the other hand, it looks very original, and most importantly, it is easier to clean the floor under the toilet.

By location, the toilet cistern can be external or hidden in a false wall niche.

The latter type is more difficult to install; in any case, it is necessary to install a partition and lay a complex outlet hose. But on the other hand, it has an original look, in the case of installing an attached toilet bowl to the false wall, a lot of additional space is freed up, the area around the device is easier to clean.

According to the materials of manufacture, toilet cisterns can be:

- Ceramic - the most common type. Ceramics are relatively durable, easy to clean, have a characteristic glossy shine and can have not only white, but also many other colors, which allows you to choose plumbing in accordance with the rest of the interior of the toilet room.

- Faience - these were the very first toilets made in the second half of the 19th century. This material is quite fragile, in addition, it has a porous structure, which makes it difficult to clean, and dirt and microbes accumulate in the pores. Modern developments make it possible to reduce these disadvantages, but still, faience as a material for the manufacture of sanitary ware for the toilet has lost its popularity.

- Porcelain toilet cisterns, like ceramic, have a smooth, pore-free surface that is easy to clean. The strength is slightly less than that of ceramics, the appearance can be very presentable. But due to the high cost, porcelain cisterns and toilets are not very popular.

- Metal cisterns for a toilet bowl surpass ceramics in strength and lightness. The characteristic dark sheen looks very stylish and is suitable for a modern washroom design. The materials most often used are stainless steel or cast iron. The latter option is more fragile and heavier, so it is better to make a choice in favor of steel tanks.

- Glass and natural or artificial stone are also used for the manufacture of toilets, so the corresponding cisterns can be purchased with them. Such products usually belong to the elite class; they are often installed in interiors decorated in Art Nouveau style. These items are expensive and can be fragile.

- Reinforced acrylic today it is widely used for the production of bathtubs, toilets, there are also toilet cisterns from it. The material is smooth, not porous, has a well-cleaned surface of a rich white color. The advantage is that, with good strength, it is lighter than ceramic, in addition, it is hygienic.

- Plastic used for toilet cisterns hidden in a wall niche. Since such a capacity is not visible, there are no visual requirements for it, the main thing is that the mechanism should function reliably.

The material and color of the cistern should be combined with the toilet: ceramic is chosen for a ceramic device, and the same steel for a steel one. The selection of tanks from other materials is carried out in the same way.

According to the method of liquid supply, the drain tanks can be with side or bottom water supply. In the first case, the hose is located on the right or left at the top of the device, in the second - at the bottom. The bottom line is good because the hose is practically invisible, there is free space on the sides of the tank. But such devices are more difficult to repair, and the water pressure for filling needs an intense one.

The shut-off device or valve for the drain tank is piston or diaphragm. The first type is operated by a lever with a piston, at its end there is a gasket that blocks the flow of water into the container. Valves with a silicone or rubber membrane allow you to quietly and in a short time fill the tank with water, but they are very sensitive to cleanliness.

There are three types of flush cisterns with a button:

- Single-mode drain - drain when all the water is poured out when the button is pressed.

- With the "stop" mode, when the first press starts the drain, and the second stops it.

- The dual-mode drain has two digits: the first is designed to drain part of the water, the second is to completely empty the tank.

In addition to the button, a stem or a lever can operate the drain mechanism. Exhaust systems drain the water by lifting the stem up. Such a tank has a rather simple device, it is easier to repair it than a design with a button. Lever mechanisms have a lever on the side or bottom, the device is triggered by pressing it. Such tanks can be compact and separate models.

External flush cisterns can be wall-mounted or angled in shape. The second type is needed if the toilet is placed in the corner of the room.

This way you can save free space in the toilet, and use the bathroom is no less comfortable than with the standard version.

Principle of operation

Both old-style flush cisterns and modern dual-mode systems have similar design and functionality.

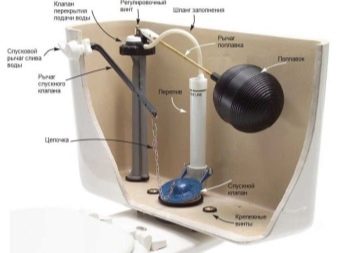

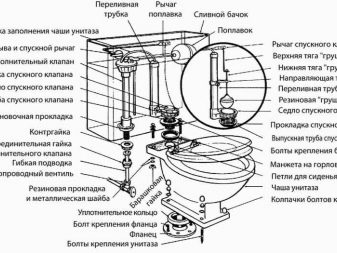

This mechanism includes the following details:

- shut-off valves;

- filling valve;

- system that prevents overflow of water.

In order to control the drainage of water and prevent unnecessary leakage of liquid, there is a drain or shut-off valve that has a valve with a plug that blocks the hole that goes into the toilet bowl. The valve is fully pressed against it under the pressure of the water in the tank. If there is a constant continuous leak in the toilet, then the device malfunction is associated precisely with the drain fittings.

The filling valve is used to pass water from the water supply to the tank and close it when it is completely filled. The scheme of work is arranged as follows: this valve has a connection, usually made in the form of a brass rod with a float, which, in turn, rises with the water level and, when filled, closes the supply of liquid from the outside. Older systems have a fill valve on the side and a float positioned horizontally; newer flush cisterns have a fill valve on the bottom and a vertical float made of lightweight plastic. Most often, toilet breakdowns are associated with this particular device.

The systems for draining and overflowing water, available on most modern models of tanks, are designed so that in the event of a malfunction of the drain fittings, float or filling valve, water does not pour onto the toilet floor, but into the sewer. For this, special hoses are provided.

If the water blocking mechanism is broken, then it does not flow over the edge of the tank, but enters through them and is discharged into the drain lines.

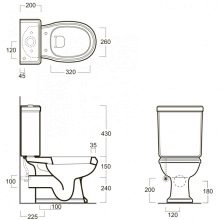

Dimensions (edit)

The volume of a standard flush cistern of a separate type or compact is 6 liters. At the same time, a ceramic product with all internal fittings weighs 10 - 11 kg. The weight of an acrylic device of the same volume will be less. The plastic container, which is built into the false wall, has a minimum weight.

Dimensions of separate cisterns or compact type can be different.

The most common options are:

- height with a lid - 350-400 mm;

- length - 300-360 mm;

- width - 150-200 mm.

To save space, the toilet is often installed in the corner of the toilet, this method is also common in combined bathrooms.

For such an arrangement, corner cisterns are chosen, compact and not inferior in volume to conventional types. The smallest similar product can be 275 mm wide. A monoblock toilet with an integral cistern can have a height from the floor to the top of the lid from 820 mm.

Components

The main functional element of the tank - internal fittings - contains the following blocks: a float mechanism and a drain system.

They, in turn, have individual components.

- The float, usually made of plastic, has an air cavity inside. This is a kind of water seal that floats up along with the water level and at a certain moment, using a system of levers, blocks the supply of liquid from the water supply.The float itself is practically not exposed to any negative influences, but most often its connecting links with a plug made of brass, other metals and plastic fail.

- To open and close the drain hole, a "pear" is intended, which rises up when the water is discharged, and when the tank is emptied and filled, it goes down again until it is completely pressed against the saddle. This happens with the help of a vertical plastic guide tube and an internal cavity. It contains air, which pushes the pear upward. This part is also susceptible to deformation, cracking, so it often has to be replaced.

- Cuff for connecting the cistern and the toilet bowl. This is not an element of a drain mechanism, but of a reliable fastening of the container and bowl. It is its tightness that determines the absence of leaks on compact models. If there are traces of moisture at the junction of the toilet bowl and the cistern, then the malfunction lies precisely in the cuff, and it must be replaced. And when installing a new part, for reliability, it is best to additionally lubricate it with sealant or silicone.

- Mounting bolts and spacers for them. These fasteners are found in compact tanks. They are not responsible for the draining process, but for the reliability and normal operation of the device, it is worth checking their condition.

- O-ring in drain and overflow systems. This part is found in modern models and often fails. It is responsible for the tightness and reliable pumping of water into the sewer in case of failure, so it is worth monitoring its condition.

The rest of the toilet cisterns components: body, lid, stem, lever or buttons. These parts are less prone to breaking, but the main thing is to monitor their integrity and wash them regularly.

Manufacturers overview

Most often, cisterns are sold complete with toilets. Therefore, in the event of a breakdown, it is optimal to choose original components for your plumbing. In this case, the dimensions will be identical, there will be no installation problems, and all the details will be harmoniously combined.

Roca victoria Are high quality faience sanitary ware from the Roca brand. It is possible to purchase 6 liter cisterns for floor-standing toilets. The products have an elegant oval shape with a glossy white shade.

The water supply is carried out from below, there are two operating modes: full drainage and 3 liter water discharge, a double metal button is provided on the lid for this. Tank dimensions: 18.5x37x39.5 cm. The product has a 10-year warranty.

Toilet cisterns complete with drain fittings Cersanit Olimpia designed for floor-standing compact toilet bowls. They are made of high quality white faience, rectangular shape with smooth corners. The water supply is at the bottom right, there is a dual mode of operation for full and half draining, the full volume of the tank is 6 liters. Product dimensions: 17x36x37.5 cm, weight with fittings - 11.9 kg.

Porcelain cisterns Keramin Grand suitable for floor-standing toilet bowls Verona, Cesaro, Keramin. Trapezoidal shape, narrowed at the bottom, white. Products have excellent appearance and reliable performance, a five-year warranty is given. Bowl dimensions: 17x38x38.5 cm.

Flushing tanks for floor-standing toilets Laufen pro have an original appearance with strict rectangular shapes. Manufacturing material - porcelain, product weight - 13 kg, water supply is carried out from the side. The volume of the tank is 4.5 liters, a two-mode drain is provided - 3 liters each and completely.

Tank with drain fittings Villeroy & Boch Hommage in appearance and form, it is very original, suitable for an elite design of a combined bathroom. The product made of porcelain has a soft glossy shade, weight - 14.5 kg, total volume - 6 liters. The water is supplied on the right, there is a double button on the top cover for a complete drain or drain of 3 liters of water.

How to choose?

First of all, the choice of a cistern, like the toilet itself, depends on the characteristics of the toilet room.For small areas, it is worth buying compact models with small dimensions. Often, in this case, it is optimal to choose a small bowl and an angular design of the drain tank, which takes up a minimum of space. Due to its greater height, the triangular profile of such a tank may not be inferior to the volume of conventional models.

Lovers of the classics sometimes, under the general style of the apartment and the bathroom, install separate cisterns with a long metal pipe, suspended high from the ceiling. But the appearance can affect the operation. The oblong pipe, as well as the joints, have to be repaired more often, it can become clogged with sediment from the tap water, and access to the tank becomes more difficult.

The most practical and reasonable option is to install a toilet with a compact type cistern., in addition, there are a huge number of design options for such a model. In the event of a breakdown, it is easier to repair them, the shut-off valves and the drain valve can be obtained by simply lifting the lid; often, for repairs, it is not even necessary to dismantle the tank itself. And they are easier to use, since, unlike separate systems, such devices can have two modes of operation.

The choice of the volume of the cistern is not very wide, the most often presented are containers of 6 liters, this is quite enough for effective work. To save water and useful space in the toilet, you can purchase compact products with a volume of 4 - 4.5 liters. Also, when buying, you should pay attention to the mass of the tank, calculate it so that the toilet bowl or frame built into the wall can withstand such a weight. The most common weight of earthenware and ceramic products in the range from 9 to 13 kg.

Installation tips

If the toilet cistern has a separate structure and is attached as a suspended one, then reliable beams should be mounted to attach it to the wall. It is best to use metal brackets that are anchored in concrete with anchors or screws with dowels. The weight of a cast iron or steel container filled with 6 liters of water is quite large and requires reliable vertical fixation.

The supply pipe at the junction of the lower opening of the tank and the drain bowl must be sealed with a rubber gasket and treated with silicone or sealant.

The compact cistern, which is installed directly on the toilet, must also be securely connected. To do this, use the bolts usually included in the kit. Place rubber gaskets at the joints. The drain opening from the tank to the bowl must be fitted with a cuff and lubricated with a sealed solution.

All pipes supplying and outputting hoses, corrugations must be tightened to the stop, ensuring reliable sealing. It will not be superfluous to check the installation of the tank strictly on a horizontal level.

Recommendations for use

A properly installed toilet cistern of any type can be used for a long time. It is necessary to wash it regularly and from time to time look under the cover, checking the integrity of the drain mechanism. In the event of the slightest leaks or malfunction, the rhinestone should be repaired.

How to fix a leaking toilet cistern yourself, see below.

The comment was sent successfully.