Paving slabs "Wave"

It is difficult to imagine a park or square, decorated without the use of paving slabs. And also this material is often chosen to decorate the local areas. Not only neat paths are laid out with tiles, but also practical platforms.

On the Russian market, this product is presented in a rich variety of brands. Buyers choose between domestic and foreign manufacturers. The Volna paving slabs are very popular and successfully compete with foreign brands.

Advantages and disadvantages

Representatives of the Volna trademark declare that they use innovative technologies for the production of tiles, including modern and functional vibropresses. Particular attention is paid to the raw materials that are selected for the production of paving stones. All components in the composition are carefully selected and tested. This is one of the main advantages of this product.

Experts have thought of a special porous structure, due to which the road surface retains its integrity and shape. The tile is not afraid of exposure to moisture, passing it through itself. And also she is not afraid of other whims of bad weather.

Do not ignore the decorative qualities of the product. The brand offers a wide variety of shades that will fit perfectly into any exterior. The manufacturer claims that even with long-term use, the color of the tile will retain its saturation. The coloring components remain bright even in contact with destructive external factors (sunlight, chemical compounds, high permeability, and much more).

If one of the tiles becomes unusable, it can be quickly changed, restoring the neat appearance of the road surface. You can carry out repairs yourself, without the help of specialists.

The special shape of the paving slabs noticeably distinguishes the product from the rich variety. Due to the amazing structure, a dynamic and expressive pattern is obtained that cannot be ignored. This form has not only aesthetic, but also practical purpose, providing a secure grip.

Designers often choose Wave tiles because of their smooth and neat pattern. If you correctly combine the colors of the road surface, you can create an original and stylish path or site. The material is suitable for different stylistic directions, allowing to embody any design idea into reality.

The composition of the road surface is completely safe for the environment, as well as for the health of people and animals.

The manufacturer adheres to the established standards of GOST, guaranteeing high quality and safety of each batch of goods.

And also buyers noted the following positive qualities:

-

an even and smooth surface on which dirt will not accumulate, making it easy to maintain the tiles;

-

another positive quality is affordable cost, which played an important role in the popularity and prevalence of the product;

-

the high strength of the tile allows it to be used in places with high traffic, since the material can withstand a maximum load of 400 kg / cm2;

-

tiles can be used not only for playgrounds and paths, but also for highways and parking lots;

-

the risk of destruction of seams, as well as deformation of the tile is minimal;

-

thanks to carefully selected materials, the tiles can boast of durability, therefore, subject to the operating conditions, the material will retain its qualities for about 25 years.

Despite the large list of positive qualities, this product also has disadvantages. Let's take a look at some of them.

-

Buyers note that the installation of the Wave tiles should be done by a professional. Only a specialist with the necessary knowledge and experience will be able to use the coating correctly.

-

According to the manufacturer, the tiles have a high and quite competitive price, but the opinion of some customers does not coincide with those stated above. They think the price is too high.

-

The last drawback is that some consignments change color quickly. Under the influence of sunlight, the color loses its expressiveness and saturation. Perhaps this is due to the fact that a counterfeit came into the hands of the buyer, in the manufacture of which a low quality dye was used. To avoid this, you need to make a purchase only in a trusted store that offers only certified products.

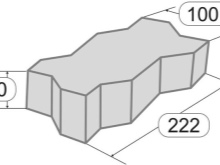

Dimensions and weight

Corrugated tiles are available in a wide variety of sizes. Manufacturers have thought of many options so that buyers can choose the road surface for a specific design solution.

The manufacturer offers the following dimensions in millimeters (length-width-height):

-

240x120x60;

-

215x105x70;

-

255x136x50;

-

264x165x70;

-

222x110x60;

-

225x112x60;

-

222x109.5x60.

These are typical pavement sizes that can often be found in hardware stores. These parameters refer to the material of different colors (gray, yellow, red and other options).

The thickness of 60 mm clearly demonstrates the high performance of the product. A also on sale you can find atypical tile sizes (300x300x30 mm, 30x30 mm, 25 mm, height 70 mm and other options). You can find it in the company store or when ordering products through the official web portal. The sizes of the original copies differ by more than 15% from the standard ones.

The weight of the tile will depend on its size. A tile in the size of 210x110x40 mm weighs 3 kilograms. With this value, the quantity per 1 m2 is 40 pieces. Before ordering a road surface, you need to make accurate measurements of the site. It is recommended to purchase the material with a margin, as some tiles may be damaged during the installation process.

Styling options

Designers have developed many options for laying paving slabs. Each of the methods differs in complexity and visual effect. In the process of laying the road surface, it is imperative to pay attention to its surface.

A quality product is characterized by smoothness. If there are irregularities and other defects on the tiles, it will be difficult to fix them. Vibrocasting tiles can be reused. It retains its shape and other performance characteristics.

Before proceeding directly to the installation, it is imperative to designate and prepare the site. The work is not complete without registration of the base. Crushed stone and sand are used for it.

In order for the result to meet all expectations, you need to carefully tamp each layer.

There are three types of styling that are most widely used.

-

The first method is standard brickwork, which is used for brick buildings. Laying is carried out with a shift of half a tile. This is a simple option, great for those who are going to do the work with their own hands, without the help of specialists.

-

Chess stacking 2 by 2 is popular. For work, you will need tiles in two colors. The layout resembles a chessboard. With this simple pattern, a rhythmic pattern is created. Elements must be connected perpendicularly.

-

The last option is parquet laying, during which the tiles are indicated by a herringbone pattern. For this scheme, you can use a coating of one or more colors.

Using paving slabs and a design approach, you can compose an original drawing from the elements. This method is often used to design parking lots or areas in front of banks, shopping centers or restaurants. Using tiles of different colors, designers create lettering, logos and other images.

The comment was sent successfully.