Plastic paving slabs

An excellent substitute for paving stones and natural stone today is plastic paving slabs for paths in the country. This building material appeared not so long ago, but it has already become very popular due to its low price, ease of installation and good durability. Now, without special skills, anyone can implement all design ideas on their garden plot or in the courtyard of the house, ennobling verandas, paths or entire sites at their discretion.

Advantages and disadvantages

The experts highlighted the main advantages and disadvantages of all types of paving plastic coverings.

Let's look at the merits first.

- Plastic tiles are lightweight and therefore easy to transport and carry.

- The price of the material is several times lower than the cost of natural stone, almost everyone can afford it.

- Simplicity of styling. No special coatings and foundations, minimal site preparation work.

- The cover can be dismantled quickly and at any time.

- Durability and long service life. Plastic is able to withstand quite serious loads, does not burst when water freezes in the gratings, it is not afraid of sudden temperature fluctuations.

- Moisture resistance. Water will not grind plastic cover like stone. The tile is impervious to moisture and does not lose its characteristics, staying in water for a long time.

- Thanks to the embossed surface, the tiles do not have a slip effect.

But this material also has its drawbacks.

- Plastic reacts poorly to the influence of certain chemical compounds. So, in particular, spilled acetone is capable of deforming the surface of the tile.

- Sidewalk plastic walkways wear out faster than concrete and stone paving stones.

- Smooth plastic tiles are highly slippery.

- The plastic cover cannot be driven by a truck. Under the weight of the vehicle and cargo, the tiles can bend, and the docking locks can break.

- Afraid of ultraviolet radiation, burns out under prolonged exposure to the sun's rays.

Features of production

Conventional and inexpensive components are used as raw materials for the production of plastic tiles:

- different pigments;

- polymers;

- quartz sand.

To reduce the cost of purchasing components, it is necessary to use recyclable materials that will be cheaper, but at the same time will not spoil the quality of products. A clear recipe for the production of tiles as such simply does not exist. Each manufacturer develops the composition himself. The best solution is to compose the components on personal experience, but in addition, experts advise using the help of a technologist.

The tile manufacturing technology is quite trivial. To comply with it, no special knowledge and skills are required.

Since the polymer that is part of the tile structure has a neutral chemical composition, only nitric acid serves as a solvent for it, under certain conditions. To form a homogeneous mixture with sand, the polymer must be melted at a temperature of 180 degrees and atmospheric pressure. This process is called extrusion.

Different inorganic substances are used to paint tiles in different colors.: iron oxide - for orange, brown or red; chromium oxide - to obtain green; titanium dioxide will give the product a white color.

Making polymer sand tiles with your own hands is carried out as follows:

- agglomeration or crushing of raw materials, however, if you purchase polymer chips, then this step is easy to avoid;

- mixing the components by means of a concrete mixer;

- melting the resulting mass in a melting and heating unit (extruder);

- molding of products by pressing;

- movement and storage of finished products.

Types and sizes

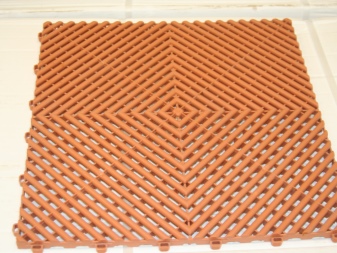

Plastic paving slabs are made of two types. The first is a lattice plastic structure with a square shape with dimensions of 300x300x30 or 500x500x50 mm. Each product has symmetrical through-slots and a weight of up to 1.5 kg. At the ends there are grooves for adhesion of light plastic elements to each other.

The second looks like an ordinary paving stone. It has a smaller size, noticeable weight, and has a wide variety of colors.

How to choose?

When choosing paving plastic, a number of parameters must be taken into account.

- Product size and thickness. The shorter the total length of the tile border, the greater the strength of the product.

- Material stability when exposed to low and high temperatures.

- Styling feature. For laying certain types of plastic products, a special base must be prepared on which the tiles are placed.

- Reputation of a manufacturer of polymer products is also important when purchasing facing material.

How to stack?

For laying the pavement on a concrete base first of all, you need to prepare it. If there are no significant flaws in the concrete, the existing irregularities can be removed with a putty. If there are paint or oil stains on the substrate, they must be removed with an acid-free product.

If laying on a wooden base, it should also not have strong differences in height, boards that have rotted should be replaced. The substrate must be completely dry and free from dust.

Laying tiles should be started from the middle. With a spatula-comb, tile adhesive should be applied to the base. Then the tiles should be laid out close to each other, tap the entire plane with a rubber hammer, remove excess glue with a rag. Let the glue dry a little before laying the next row.

When several rows have been laid, roll the entire laid tile with a tamping roller.

Laying polymer paving slabs on the ground is also quite simple, you can do it yourself. To do this, you will need the most uncomplicated construction tools, as well as:

- coarse river sand or washed sand;

- medium-fraction crushed stone or gravel;

- cement grade PC-400;

- plastic paving stones or tiles;

- plastic or concrete curb.

For the construction of sidewalk coatings from polymers, two similar technologies are practiced: laying on compacted sand and creating a cement-sand base. For both methods, it is necessary to carry out the following types of work:

- marking (it is advisable to adjust the width of the coating to the size of the product so that you do not have to cut the material);

- removal of 25-30 centimeters of the topsoil;

- installation of a curbstone;

- laying geotextiles at the bottom of the trench;

- filling and compaction of the drainage layer of crushed stone or gravel 10-15 centimeters high;

- laying geotextile fabric on the drainage layer;

- filling and tamping a layer of sand 5-15 centimeters high.

As a rule, plastic paving stones are laid on clean sand, as they are thicker and have less surface area. This material, collected in a one-piece coating, is more resistant, without the need for a particularly strong base.

A thinner polymer paving slab is placed on a dry mixture of sand and cement in order to have a solid base under the wider elements. It will give stability to single tiles even when weight pressure is applied to their edges.

Due to the flexibility and strength of the tiles, building a stronger concrete base is usually not required. The decision on its construction is taken only when there are unstable and heaving soils on the site.

In such situations, the sand leveling layer is replaced with reinforced in-situ concrete.

The cement-sand mixture is prepared from washed or river medium-fraction sand and cement grade PC-400, in a ratio of 1: 5. Mixing is best done in a concrete pit to obtain the required quality level.

The order of laying tiles on the track is as follows:

- lay along the curb about a meter row of paving stones or paving polymer tiles, leveling the dies in height with a rubber mallet;

- put one row along the width of the sidewalk or path, in parallel, controlling the presence of the required slope with the building level;

- thus fill the entire area with paving stones or tiles.

After laying and tamping the tiles, dry sand should be scattered over the surface of the laid slabs and scattered along the seams. To do this, the material should be placed on the surface with a soft brush, filling all the voids. Then the surface must be well cleaned of the remaining sand and spill cracks from the watering can with a small amount of water in order to moisten the sand or sand-cement pad.

The comment was sent successfully.