All about plasticizer for paving slabs

As part of paving slabs, the plasticizer simplifies the laying of the material, making it more resistant to external influences. Its presence increases the strength and durability of the plates during operation. Let's find out more about this useful component that you can make yourself.

What is it and why is it needed?

The composition of outdoor tiles, known for their resistance to moisture, low temperatures and mechanical stress, includes several components - crushed stone, gravel, sand and cement. But at the same time, it always includes a plasticizer for paving slabs, which increases the quality, technical and operational characteristics of the material.

-

The additive is needed to harden the tiles - due to its presence, the strength increases by 25%. In addition, it reduces the porosity of the structure, which is not only a defect, but also makes the pavement surface less reliable.

-

Using a plasticizer, it is possible to reduce the consumption of water by 35% and of the cement mixture by almost 15%., and the hardening of concrete is faster.

-

The universal composition of the additive for the manufacture of outdoor slabs increases their frost resistance, at the same time, the hydration of the liquid amorphous, cement mortar at sub-zero temperatures improves, it sets and hardens faster. This allows installation in cold weather.

-

The plasticizer helps to increase the flowability of concrete... This is an important parameter of the tile material, since it makes installation easier, and the formation of a monolithic coating is of higher quality. This useful component for the production of paving materials allows for installation on horizontal and vertical substrates, eliminating the process of vibration laying.

The main components of the composition of plasticizers are polymeric and mineral substances, as well as surfactants. When using such a filler, the surface of the slabs is smooth, free from defects, the formation of irregularities and chips is excluded, no efflorescence is formed on the basis of the product, the planned color of the paving slabs is preserved.

Operation in winter does not affect the structure of the material in any way, it will not crack, and its shelf life will increase significantly.

What are they?

Depending on the composition, plasticizers are divided into several categories, because of this, the properties of each product may differ significantly. Such products are manufactured in factories in various forms and are manufactured using special technologies.

There are multifunctional plasticizers for concrete, the composition of which includes the components necessary to improve almost all the basic characteristics of the tile. But there are also highly specialized additives that increase certain important parameters of the building material.

-

Excipients to increase the cold resistance of the tile.

- Activators, contributing to the rapid set of strength of concrete mixtures. They increase the level of resistance of plates to external mechanical compression, reduce the duration of their exposure, and accelerate the production process of a material of a particular grade. At the same time, the design strength of concrete in the composition of the paving slab increases, its invulnerability to the effects of water and frost.

- Modifiers - components that strengthen the composition of the products, simultaneously helping to maintain the mobility of the concrete solution, which is important for the most uniform distribution.

- Complex supplementsthat improve the structure of the mortar and its parameters, which has a positive effect on all the characteristics of the facing material.

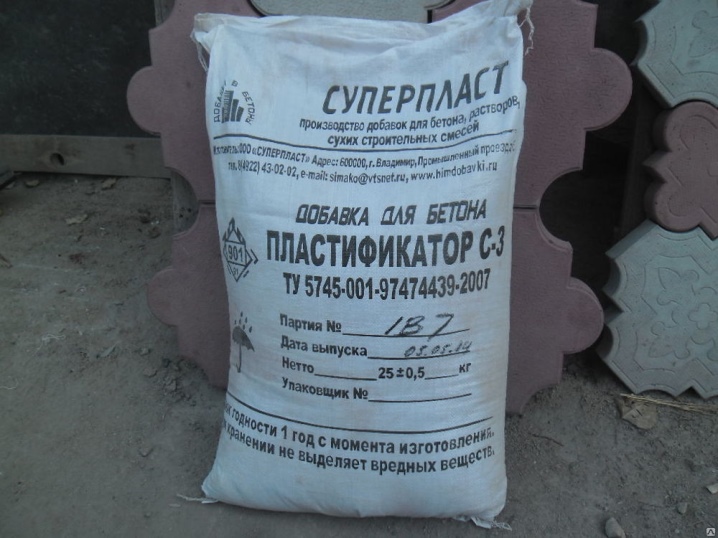

- It is worth remembering separately about filler C-3, designed for self-compacting mortar during the manufacture of tile building materials. Its application helps to do without vibrocompression.

There are two types of plasticizers by type. Liquid can be used for the manufacture of plates, the installation of which takes place in the cold and warm seasons. Dry the type of filler is usually intended for use at temperatures from –2 degrees and below.

Thus, the best plasticizer is a composition that is correctly selected taking into account the volume of work and operating conditions, and one or another type of plasticizer is necessarily added to a vibropressed plate for outdoor use.

Instructions for use

Special additives in the form of powder or liquid should be added to the cement slurry according to the order specified in the manufacturer's instructions. For street paving stones, a certain amount and proportion of all components is provided. If the plasticizer is made in the form of a powder, then it must first be diluted with water, but the additive can be introduced into the concrete mixer when other ingredients are mixed with water.

Let's consider in detail the recipe for using a dry modifier.

-

It is necessary to dilute the additive in water... If it is C-3, then its concentration should be no more than 38%. In this case, the building rate of the ratio of water and powder is 2: 1.

-

Then the consumption of the solution for thickening the concrete is determined.

-

Dissolved plasticizer is poured into water and cement is added to it.

-

The components are sent to the concrete mixer. It remains to wait for high-quality mixing until complete homogeneity.

The liquid additive is mixed in a suitable container, and then added to the water in the right amount and thoroughly mixed. The solution is poured into the drum of a concrete mixer, after which cement and filler are placed there. However, it is worth knowing that an excessive amount of plasticizer introduced into the composition can increase the hardening time of the concrete mixture.

What can be replaced at home?

For the manufacture of outdoor tiles, instead of a plasticizer, you can use improvised tools that can be found in every home.

Suitable as an additive:

-

ordinary slaked lime;

-

tile adhesive;

-

polyvinyl acetate glue (PVA);

-

different detergents - laundry soap, washing powder, dishwashing liquid or shampoo;

-

any foam stabilizer.

Most often, detergents are used for this purpose - they are a good replacement for special additives, but it is important to correctly calculate their amount. Powder or soap is ideal when using cement and expanded clay, but you need to add them to the working mixture immediately before pouring into molds. A smooth surface can also be achieved by placing lime in the concrete.

For information on how to use the C-3 plasticizer, see the next video.

The comment was sent successfully.