Water repellent for paving slabs

When arranging a backyard with paving slabs, it is important to take care of its protection from the destructive effects of atmospheric precipitation. The water repellent copes with this problem. From the material in this article, you will learn what it is, what it happens, who releases it. In addition, we will show you how to choose and use it correctly.

What it is?

Water repellent for paving slabs - a special hydrophobic impregnation "wet effect". This is a material with a specific composition, it improves the appearance of the coating, increases its performance. This varnish is used so that the surface of the paving stone does not get dirty during operation.

The impregnation has a decorative and practical function. It increases the strength properties of paving slabs, changes its shade, and gives an unusual effect. Protects the surface of the laid out material from high humidity, temperature extremes, ultraviolet radiation, salts, acids.

The varnish used is easy to maintain and use. It is reliable, completely covers the joint seams. Has anti-slip effect, prevents the formation of mold and moss.

Makes the treated substrate water-repellent. The varnish increases the frost resistance of the paving stone.

A hydrophobic agent with a “wet stone” effect is supplied to the Russian market mainly in a ready-made form. Stir before applying. At high viscosity, dilute with a special solvent (for example, white spirit). This tool makes the shade of the coating brighter and fresher.

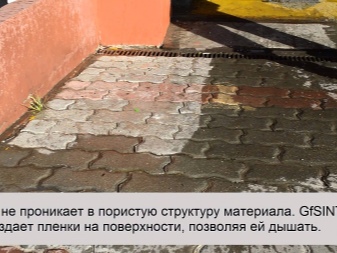

The tiles are covered with a water repellent immediately after laying. It has deep penetration into the porous structure of the laid material. After processing, a high-strength film remains on the surface. It does not collapse, prevents the formation of efflorescence (white spots).

It is not waterproofing: the hydrophobic impregnation does not reduce air permeability. It creates a vapor-permeable type of coating without disturbing the porosity of the tile. However, the effect of water repellents depends on the duration of exposure to moisture on the tile. The larger it is, the weaker the efficiency.

The application of a hydrophobic composition increases the resistance of the base to mechanical stress. The varnish reduces the frequency and volume of repairs. Based on the type of drug, the treatment is performed 1 time in 2, 3 years, sometimes it is performed 1 time in 10 years.

Description of species

A hydrophobic preparation for paving slabs can have a different composition. Its base is water, silicone, acrylic. Each type of product has its own characteristics and differences. Knowing them, it is easier to choose the option necessary to protect a specific site in different regions of the country.

Tile hydrophobization can be surface and volumetric. Surface involves watering, spraying and distributing the product on the front surface of an already laid stone.

In addition, it includes the piece-by-piece processing of fragments, which implies the immersion of each module in a special composition.

If individual parts are processed by dipping and then drying, you have to wait until they are completely dry, It is unacceptable to lay them while they are wet. This reduces the level of protection and causes destruction of the protective layer.

Volumetric hydrophobization is performed at the stage of paving slab production. Such a stone is protected not only inside and outside.There is also a forced water protection, it involves the introduction of a hydrophobic drug under pressure through holes pre-drilled in the tile.

Consider the distinctive features of water repellents that are used on the laid out paving slabs.

Water based

Such hydrophobic agents are made by dissolving silicone fats in water. When penetrating into the rocky structure of the tile, silicone grease closes the pores. Therefore, after processing, water cannot get into them. The products of this line stand out for their low price, but their effectiveness is short-lived (only 3-4 years).

There are no toxic components in these preparations. They can be used to cover tiles in garages and gazebos.

The practice of using the compositions in our country shows that the number of treatments for paving slabs to maintain their operational and aesthetic properties is 1 time in 2-3 years.

Alcohol

In terms of performance, these products resemble their aqueous counterparts. These hydrophobic formulations are more versatile and have improved penetration. They can be impregnated with pavement areas located on the street (garden paths, areas near gazebos and verandas, porch, entrances to the garage). However, the volatile components of these formulations are not suitable for indoor use.

They create a particularly durable coating, they are used to cover silicate bricks, natural, artificial stone. They are distinguished by antiseptic qualities. They are used less often than analogs on a water basis, they prevent dust and dirt formation.

Polymer

Polymer-based products are recognized as the best products for the treatment of paving stones, which are operated under conditions of increased stress. Their gas permeability is not less than their water counterparts. They are distinguished by deep penetrating ability. These materials are applied on a dry surface, choosing not too hot days for work.

Polymer-based impregnations dry quickly, do not wash out during operation, do not change the color and tone of the tiles. They serve as surface protection for a very long time.

They protect it from the formation of microcracks and chips, increase the durability of the tile. They are used once every 10-15 years, while the multiplicity depends on weather conditions and the volume of loads on the base.

Review of the best manufacturers

The modern market for hydrophobic products offers buyers a lot of products for protecting paving slabs. The rating of the best brands includes several brands: Ceresit, VOKA, Sazi. Let's mark the best products of the companies.

- "Tiprom M" ("Tiprom K Lux") - high-quality water repellents with a long-lasting "wet stone" effect supplied by the Sazi trademark. They are distinguished by the guarantee of comprehensive protection of the treated surfaces. Suitable for covering stones in difficult places, they have a high penetrating power.

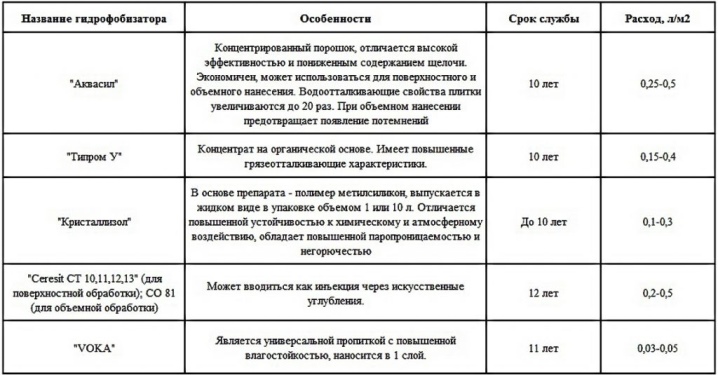

- Ceresit CT10 - protective hydrophobic varnish based on organic silicone. Used for comprehensive protection, has a wet stone effect. Effectively protects the stone from mold and mildew.

- Impregnat Dry - a preparation with deep penetration into the tile structure. It is intended to be applied in 2 layers, creates a durable frost-resistant coating.

- VOKA - a universal waterproof preparation for paving slabs. It is supposed to be applied in 1 layer, it can penetrate into the structure of the stone by 3-5 mm. It is considered a remedy with a long-lasting effect (up to 10 years).

Among other formulations, experts advise taking a closer look at some other products.

- "Aquasil" - a concentrated mixture that reduces the water absorption of porous materials. It can be used to coat the surface, increasing its strength and durability.

- "Spectrum 123" - a concentrate with a silicone component, intended for the processing of porous materials. Prevents pathogenic bacteria and mold.

- "Tiprom U" - water-repellent impregnation, preventing surface contamination.Designed for surfaces that constantly interact with water.

- "Armokril-A" - deep penetrating hydrophobic compound for concrete tiles. It is produced on a polyacrylate base, used for pigmented tiles.

Nuances of choice

Not every type of water repellent on the market is suitable for processing paving slabs. Information on the appropriate type of product should be found in the instructions for a specific drug. Even universal substances are not all effective on horizontal surfaces.

It is better to select those options that are intended directly for paving slabs, help fight moisture and efflorescence (for example, GKZH 11).

It should be borne in mind that individual products can be sold in concentrated form. This is important for calculating the flow rate.

Do not assume that concentrated products do a better job of protecting tiles. If they are not diluted, as written in the instructions, unaesthetic stains will appear on the surface of the base to be treated. It is necessary to choose a water repellent according to the type and quality of the surface.

You need to buy this or that option from a trusted supplier. In order not to doubt the quality of the goods, you need to demand from the seller the appropriate documentation confirming the quality of the goods. It is necessary to pay attention to the possibilities of the means: not all of them can make the surface saturated and glossy, like after rain.

During the purchase, you need to pay attention to the expiration date. After its expiration, the properties of the product change, so the protection of the treated surface may be ineffective. You should not take the composition for future use. It is taken just before processing.

Application Tips

The method of processing the base does not differ from coating the surface with paint. Before applying the composition, the base is inspected. It is important that there are no slopes and subsidence in it. It is important that the substrate is clean. If necessary, you need to get rid of debris, dirt, oil and other stains.

If cracks are visible on the surface, they are repaired. Replace damaged tiles with new ones. Depending on the volume of work, prepare an appropriate container for varnish, a roller and a brush. Before starting work, perform a trial processing of a small area in an inconspicuous place.

The water repellent is applied exclusively to a dry surface. If it is wet, some formulations will not be able to create an effective protective coating. Such surfaces can only be treated with alcohol-based compounds.

After inspection and preparation of the base, they begin processing. The water-repellent composition is applied to the paving stones with a roller or brush. Sometimes a special spray is used instead. If chips or scratches are noticeable on the fragments of the tiles, they are processed at least two or three times.

The 2nd layer is applied only after the 1st layer has been absorbed. It should be completely absorbed, but not dry. On average, the approximate absorption time under optimal conditions is 2-3 hours. The varnish layer should not be thick. Excess substances that remain on the surface are removed with a soft absorbent sponge or cotton cloth.

Usually the hydrophobic varnish is applied twice. This allows the effect to be fixed. In this case, the consumption of the drug will depend on the moisture content and porosity of the base itself (the higher the porosity, the more).

To avoid poisoning and allergic reactions, protective clothing and a respirator are used when working with varnish. The material is highly flammable. You can work with it only where there are no open fires nearby. The air temperature should be at least +5 degrees. In rainy and windy weather, processing is not carried out. Otherwise, dirt and dust will spread to the coating.

Water repellent test, see below.

The comment was sent successfully.