Geotextiles for paving slabs and paving stones

Garden paths, paving stones, paving slabs will remain intact the longer the stronger the base underlying them will be. Geotextile is considered the most effective initial coating today. The material is available in rolls and its properties help to increase the lifespan of the top layer.

What is it and what is it for?

The rolled material is really very convenient - it reliably separates the levels of the base of the garden path, removes water (from rain to thawed) into the ground, does not allow weeds to germinate through the tiles, which, of course, spoil its appearance. Geotextile is also often called geotextile... Its function is a substrate, it is a synthetic canvas, elastic, with moisture permeability only in one direction. Geotextiles are made from nylon, polyester, polyamide, polyester, acrylic and aramid. Fiberglass is also used if you have to stitch the fabric.

High-strength material is its main advantage. In addition, he is not afraid of such negative factors as external influence, mechanical or chemical. It cannot be deformed by rodents and insects. It does not rot, and even frost is not afraid of it. But all these qualities do not prevent it from allowing moisture to pass to the drainage of the garden path or paving slabs.

Geotextile will not allow the soil to swell in the cold season, during freezing.

Briefly about the purpose of geotextiles:

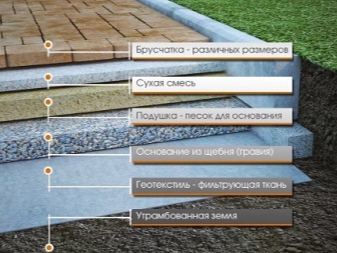

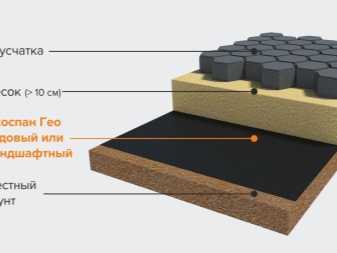

- the material looks like a zoning layer between soil, sand, rubble, and this makes it possible for each layer to remain in its place with full functional consistency;

- preserves the structure of the soil in the context of high humidity indicators, as well as as a result of heavy rainfall;

- does not allow the soil itself and sandy, crushed stone layers to wash out;

- blocks the path of weeds that can quickly occupy even paving slabs;

- in conditions of winter freezing, it blocks the swelling of the lower soil layers;

- prevents soil erosion.

The use of geotextiles is appropriate in the situation of laying paving slabs on the territory of recreation areas and in the house sector. Geotextile helps to create the correct drainage layer: water that accumulates in the upper soil layers is smoothly and calmly drained into the ground. Geosynthetics is experiencing a boom in demand, which is also facilitated by the wide choice that manufacturers provide.

Description of species

Absolutely all geotextiles are classified into two groups: woven and non-woven... Non-woven options are more popular as they are very durable and cost less. By the type of raw materials are distinguished polyester material, polypropylene and mixed... Polyester is afraid of acids and alkalis - this is its weak point. Polypropylene is stronger and more durable, it is resistant to the external environment, perfectly conducts water and is not afraid of decay.

Blended textiles are based on safe recyclable materials, which is why they are cheap, but not as durable. Natural threads in its composition rot faster, which leads to the formation of voids - and this affects the efficiency of the geotextile.

Knitting and stitching

The structure of this woven geosynthetics consists of polymer longitudinal fibers, which are stitched with a special thread of the transverse type. It is inexpensive, accessible option. If it is laid correctly, the fabric will perform all its functions flawlessly.

But the knitting-stitching type has a drawback - it does not have a fixed fiber connection. That is, fibers can fall out of the web. The disadvantages include not the most reliable fixation to the soil during interlayer installation.

Needle-punched

It is a non-woven fabric containing polyester and polypropylene fibers. The canvas is pierced, water penetrates as a result of this only in one direction. And also small soil particles do not get into the punch holes. Price, quality and reliability balance harmoniously in this type of geotextile.

For European parks and gardens, this version of the canvas is considered the most popular. The material has elastic pores that do not interfere with filtration, allow water to seep into the soil and exclude its stagnation. Which, of course, is extremely important for those regions where high air humidity is the norm.

Thermoset

This manufacturing technology makes it possible to create a material with a reliable connection of polymer fibers precisely by heat treatment. High temperatures help to achieve high-strength characteristics of the fabric, its durability. But this geotextile is not cheap: of all types, it is the most expensive.

Popular manufacturers

There is a choice: you can purchase both domestic geotextile and a product of foreign manufacturers.

- German and Czech brands today they are leading the market. Company "Geopol" is considered to be the top-ranked manufacturer with a good reputation.

- As for domestic brands, the most popular are Stabitex and Dornit. The products of the latter brand are designed for the formation of pedestrian-type paths, as well as sites with not the highest load. But in parking lots, on car entrances, it is more profitable to lay textiles of the Stabitex brand.

The price of the material is on average 60-100 rubles per square meter. The length of the roll depends on the density of the fabric - the higher the density, the shorter the roll. Geofabric used for garden paths is sold at about 90-100 m per roll. The width of the material is from 2 to 6 m.

Which to choose?

The main thing to look at is the technical specifications. They are indicated in the accompanying certificate, which must be present without fail. If these are pedestrian paths, sidewalks with medium traffic and load, then a certain material should be used.

- Density in the range of 150-250 g per square meter... The more load is planned, the higher density is required.

- The potential elongation ratio must not exceed 60%. Otherwise, it is fraught with subsidence of layers and further disruption of the consistency of the top coating.

- The most successful material used as the basis for geotextiles is polypropylene. It guarantees a long service life and high strength.

- It is imperative to make sure of the strength of the fiber connection or the strength of the punching web. If the fabric is easily separated, if pulled out after an elementary pressure with a finger, it is better not to use this product.

When choosing a material, possible alternatives are also taken into account: for example, if they do not really trust such an innovation as landscape textiles, and want to do with the classic solution. In this case, you can pay attention to roofing material, as well as a dense polymer plaster mesh. But roofing material, it is worth noting, is short-lived. At least when compared to geotextiles. Plastering mesh can let the water go up - this, in turn, will wash the paths when the snow melts in the spring.

Laying technology

Usually geotextiles are laid twice according to the classical technique. First, they put it on the bottom of a trench, which has already been rammed.

The first laying of geofabric is carried out in a specific order.

- First of all, the soil is removed to the desired depth, it is leveled.

- Sand is poured onto the trench bottom with a layer of 2 cm thick, 3 cm is an extreme option.

- The surface must be carefully tamped.

- At the bottom along the trench itself, as many geotextile canvases are laid as required by the calculation. The canvases should be parallel, taking into account the overlap and wrap-around on the walls. The approximate width of the inlet is 20-25 cm; it will have to be wrapped on the walls 25-30 cm.

- The canvases must be laid with fixation with metal brackets. Soldering is also possible if it is polyethylene or polyester polymers. It is permissible to use an industrial hair dryer, a soldering torch.

If you put the geotextile for the first time, you can make a test sample: solder two small pieces of fabric. When the workout is successful, you can join large canvases. You need to lay with longitudinal and transverse joints, using a professional stapler. But then, in addition, you will have to glue the seams with a hot bituminous compound. After it was possible to lay the geotextile along the trench bottom, a sand layer of 2-3 cm is poured onto it. And the crushed stone layer needs to be poured only on top of it, without breaking the sequence. It is imperative to take sand: if this is not done, the sharp edges of the stones can pierce the canvas during tamping. And a thin sandy layer will not interfere as a bedding on the drainage top, where the second layer of geotextile will lie.

This second layer of geotextile eliminates sand leaching from the bedding bed, which is possible under the influence of downstream moisture. This layer is placed when the curbstone has already been installed. On the sides, you need to make a slight overlap. The material is fixed in the same way as in the description of fixing the first layer. Only the larger metal brackets will be required. After the geofabric is laid under the garden path, a sand cushion (or a mixture of sand and cement) is lined on it. This will be the optimal layer for laying tiled sidewalk. Each fill layer requires careful compaction.

Of course, it is important not only to correctly, consistently lay the fabric with the right side. It is important to choose the very option that will meet the request.

The comment was sent successfully.