How is the repair of petrol cutters carried out?

The maintenance of a personal plot or an adjoining territory is not complete without the help of a petrol cutter. In the warm season, this tool gets the maximum work. Before you start using the brushcutter, you should prepare it correctly. It is also important to monitor the serviceability of the tool and eliminate breakdowns in time. You can deal with the most common malfunctions on your own by learning a little more about the petrol cutter.

Device

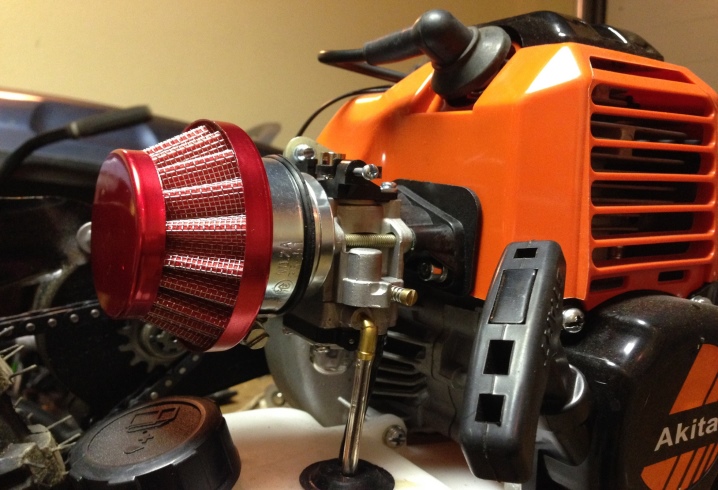

Petrol trim tabs are simple. The main element of the tool is a two-stroke or four-stroke internal combustion engine. It is connected by means of a gearbox to a shaft that transmits the force to the cutting element. The wire connecting them is hidden in the hollow shaft. Also located next to the engine is the carburetor, air filter and starter (starter).

The motocross mows the grass with a fishing line or knife, which can rotate at a tremendous speed of 10,000-13,000 revolutions per minute. The line is mounted on the trimmer head. The section of the string is from 1.5 to 3 mm. The main disadvantage of this type of cutting element is its rapid wear. As a result, you have to rewind or replace the line, sometimes this is done with the change of the bobbin.

The fishing line is most often used when mowing grass, and for removing bushes and dense thickets, it is better to give preference to knives (disks). They can be of different shapes and sharpening.

The blades and gearbox are covered with a protective cover, which ensures safety during work. It has special holes through which grease is supplied. To make the brushcutter easier to use, it has a belt with a fastener. It allows you to evenly distribute the weight of the unit, making it easier to work with it.

A handle is attached to the bar of the petrol cutter, on which there are buttons and levers for control. The handle can be U, D or T. To refuel a brushcutter with a two-stroke engine, a mixture of gasoline and oil is used. It must be poured into the fuel tank.

In four-stroke models, gasoline is poured into the fuel tank, and oil separately into the crankcase.

Symptoms of common problems

Knowing the internal structure of the petrol cutter and the principle of its operation, you can easily troubleshoot with your own hands. Some breakdowns are most common and are distinguished as the main ones.

- Engine faults should be looked for if the brushcutter does not work or does not even start. You should also pay attention to this part of the braid if unusual noises are heard during operation or strong vibration is felt. A clogged air filter can also cause engine problems.

- If fuel does not enter the combustion chamber, then you should look for the cause in the clogged fuel filter. It is also worth looking at if the tool does not run at low speeds.

- There is no spark. This is not uncommon when the spark plug is flooded with fuel.

- The brushcutter bar vibrates strongly, which makes it more difficult to work with it.

- The reducer is overheated in a short time, which is felt during the operation of the scythe.

- At low rpms, the line turns poorly, which affects performance.

- The starter grille is clogged - the reason for the engine overheating and stopping operation. The starter motor can also fail when the cord breaks when starting too abruptly.

- Carburetor clogging can be due to the use of low quality fuel.It is also important to pay attention to the carburetor in time if the mixture is flowing.

- The petrol cutter stalls after switching off if the carburetor is not set correctly.

Remedies

It is best to start repairing petrol cutters with a step-by-step check of the main components. The first thing to check is the fuel in the reservoir, as well as the presence of lubricants on the main components of the tool. It is also important to know what quality and what is the proportion of fuel and oil used. If something goes wrong, the piston system can fail, and its replacement is expensive.

Next, it is worth assessing the serviceability and performance of the spark plugs. The result is judged by the presence of a spark when there is contact with the tool body. If the fault is in the plug, then you need to remove the voltage wire from it.

Then the candle is unscrewed with a special key.

In case of contamination, it is recommended to replace it with a new one and dry the candle channel. They also do this if there are cracks or chips on the candle body. The gap between the electrodes is set at 0.6 mm. Clamping a new candle is also done with a special key. At the end, a voltage wire must be connected to it.

It will be useful to inspect filters, both fuel and air. If the blockages are strong, then replacing them is the best solution. The air filter can be washed with water and detergent and then dried. It is also sometimes soaked in gasoline. After drying and installation, it is important to wet the filter with oil, which is used in a mixture with fuel.

It is very easy to fix the problem in the form of a stalling petrol cutter immediately after starting - it is enough to adjust the carburetor according to the scheme given in the documentation. Sometimes you have to loosen the carburetor valves to make it easier to feed the mixture into it.

Sometimes the brushcutter stalls due to the intake of a large amount of air. In this case, it is necessary to increase the engine speed in order to release it. Also, be sure to check the fuel hose for possible damage. If necessary, change it to a new one.

It is important to keep the gearbox clean and its gears must always be treated with special grease. It is worth noting that it is not always possible to repair the gearbox and starter on your own, therefore, it is more advisable to replace them with new ones if these units break.

When reducing engine power, you should pay attention to the exhaust muffler, or rather, to the mesh in it. It can become clogged with soot from burnt oil. This malfunction is solved by cleaning the mesh. This can be done using a small wire or nylon bristled brush and compressed air.

The clutch in petrol cutters can break due to wear of the pads or a broken spring. In both cases, defective parts are replaced. Sometimes the clutch becomes unusable, it can also be replaced with a new one. Moreover, both fully assembled couplings and separate elements for them (washer, drum, etc.) are on sale.

General recommendations of specialists

Avoiding repairs and contributing to the long service life of the mower is a snap. The first thing to start with is to read the instructions before starting. It is important when the brushcutter is in use to monitor how well the engine is cooled. Be sure to keep the starter and cylinder ribs clean. Otherwise, the engine can quickly deteriorate due to overheating.

Periodic engine maintenance can significantly extend the life of the brushcutter. It consists in constant inspection and cleaning of the motor. To wash a cold engine, a soft bristle brush is taken. It needs to remove dirt from the surface. and.

Plastic parts are cleaned with special solvents

Fuel must not be left in the brushcutter for more than 30 days. If the mower will be idle without work, it is better to drain the fuel mixture.For most tools, 92 gasoline is suitable, which in no case should be replaced with diesel fuel or gasoline with a lower octane number. It is best to use oil for two-stroke engines in the mixture. It is not recommended to make fuel compositions for future use, as they eventually lose their original properties and can lead to breakage of the brushcutter.

At the end of the frequent use of the spit, for example, with the arrival of late autumn, the petrol cutter should be prepared for storage. First you need to drain the fuel mixture and then start the engine. This is necessary so that the remaining mixture in the carburetor is used up. After that, the unit is thoroughly cleaned of dirt and stored. If you follow the brushcutter correctly, then even the Chinese one can show high performance for a long time.

For information on how to repair petrol cutters, see the next video.

The comment was sent successfully.