The benzokos stalls when you press the gas: causes and remedies

A petrol cutter and a petrol trimmer are machines that do not just mow the grass, but cut it up to several times more than their counterparts with an electric motor. Once a brushcutter or a petrol trimmer stalls for a while, and the mowing process is immediately slowed down.

Diagnostic features

A well-posed question is already half the answer. The fact will significantly speed up the search for a solution - under what circumstances a petrol trimmer or a petrol cutter stalls, namely:

- immediately after the start;

- when it has been idling for some time - after one or several minutes;

- when you press the gas button (or knob) - or shortly after starting work at high, near-maximum speeds;

- under heavy load (for example, to prune bushes, mow dense and tall weeds);

- when warming up in the cold - it heats up unnecessarily (the brushcutter has stalled due to overheating);

- after opening the air damper.

Depending on which of the circumstances was clarified during the pre-diagnosis, the elimination method searches for a more specific cause of the brushcutter or trimmer malfunction.

Main reasons

The following reasons are possible, on which the brushcutter or trimmer stalls when trying to restart and continue the interrupted work:

- engine problems;

- failure in the gasoline and oil supply system;

- damage to pipelines (capillaries, hoses, nozzles);

- malfunctions in the ignition system.

A general description of scythe or trimmer problems is not enough here. A clear and immediate repair, high-quality service is impossible without specifying the identified cause.

When gassing

You press the gas and the trimmer stops working, does not develop speed. Possible suspected causes are:

- the carburetor setting is out of order, which appears with an increasing load on the drive itself - after its long idle time or when working in extreme conditions;

- the fuel valve is clogged with deposits;

- the carburetor cable is loose and sag;

- the fuel supply hose is unnecessarily stretched, possibly torn;

- the check valve (breather) is clogged with deposits - fuel does not enter the fuel tank.

Important! Malfunctions in the carburetor itself give themselves away by vibration of the petrol cutter.

With an increase in revolutions

If the brushcutter (or trimmer) stalled when adding engine speed - check the device according to the following signs:

- clogging or sticking of the valve built into the gas tank cap;

- violation of valve adjustment;

- malfunction of pistons and cylinders - from vibration during the operation of the scythe or trimmer, accidental blows directly during the mowing session;

- violation of the supply of the air-fuel mixture;

- extra pumping air into the motor;

- cracking of the fuel inlet hose, loosening of its connections.

When the air-fuel mixture is supplied in the required portions to the engine out of time, the engine burns the amount that has managed to flow since the last stall, and itself stalls again.

When idling

When you start the trimmer or brushcutter at idle, you find that the device starts up - but stalls after, say, 5-10 minutes. The reasons may be as follows:

- clogging, violation of carburetor adjustment;

- initially incorrect setting of the carburetor valve mechanism;

- clogging of the air filter;

- reduction in the speed of the gearbox (if any) - the wrong ratio of the air-fuel mixture;

- clogging of the throttle;

- the penetration of excess air into the fuel system;

- running out of fuel in the tank (and oil in the tank if the engine is four-stroke).

If there are problems directly with the carburetor, the machine will stop both after a cold start and after starting on an already running engine.

Immediately after the start

Stalling of brushcutters or trimmers immediately after the start is due to the following reasons:

- imbalance of previously adjusted valves;

- initially incorrect setting of the valve mechanism;

- clogging of the fuel supply valve by deposits;

- the hose is worn or loose.

Due to the broken fuel injection algorithm, the petrol cutter or trimmer vibrates strongly in operation.

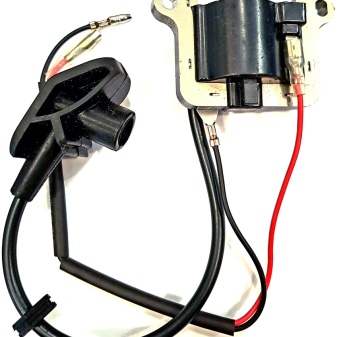

In the process of warming up the engine

If the engine heats up too quickly, overheats - the brushcutter or trimmer works unevenly, as if in jerks. After which it will stall. The reason may be as follows:

- boiling gasoline;

- the ignition wire is damaged (poor insulation);

- the coil in the ignition system has noticeably burned out, inter-turn short circuits have appeared.

The same heating is observed when using a rotary (rather than disc) damper.

When the air damper is opened

The petrol cutter or trimmer stalls when raising the damper for the following reasons:

- pumping excess air due to a cracked fuel suction hose;

- oil seals are worn out;

- improper functioning of the metering unit of fuel and air when they are mixed.

In this case, the brushcutter stops immediately.

Ways to eliminate breakage

By carburetor are possible the following works:

- cleaning and adjusting the fuel supply valve;

- similar work with a valve that releases exhaust gases and vapors (after fuel combustion);

- replacing the weaker spring on the inlet valve;

- restoration of the tension of the carburetor cable;

- replacing the fuel suction hose, checking and strengthening the loosened connection;

- change of the rotary disc damper;

- change of a faulty wire or ignition coil.

The list of work carried out may also include cleaning the injectors (in a 4-stroke engine), replacing valve washers, gaskets in tank plugs, and so on.

Operating tips

It is worth paying attention to several recommendations for working with a petrol cutter or trimmer, extending the service life of the device up to several times.

- As soon as you notice that the petrol cutter or trimmer is vibrating, stop working immediately and check the serviceability of specific parts.

- Adjust the valves and check the operation of pistons and cylinders, clean and change the injectors, starting from the requirements set out in the user manual and the recommendations of the service center masters.

- When air bubbles enter the system due to a broken fuel hose, apply gas. When gasoline burns with a higher engine speed, there will be fewer gas bubbles. But this is a temporary measure. Disassemble the unit as soon as possible and eliminate the cause of excess air intake.

- Do not operate the unit in cold weather without warming up the engine - under load it can often stall. The effect here is the same as in the case when the driver started the car at -40 and drove off immediately without waiting for the engine to warm up.

- Do not leave the machine on the road. In the event of an accident, impact, it will immediately break down, and this will make the purchase of a new unit a compulsory measure. The car that crashed into it, at best, will receive damage to the body and bumper.

- Avoid working with a brushcutter or trimmer in a rainstorm. The ingress of water with air in the worst case can cause the engine to explode. Similar situations have arisen with cars.

- Do not use untested car oils and lubricants. The mower warms up the engine more than the car itself would do - if it overheats, the car oil will lose its lubricating properties.It will turn into a burnt out reagent - sticky, overly viscous and viscous, like fuel oil. It will immediately stop (and shut off) the engine.

- If the oil is old, previously drained from the tank of a machine or another (or the same) lawn mower (on a 4-stroke engine), settle it, filter it to remove dirt and metal. But get fresh engine oil as soon as possible.

- If the engine is two-stroke, observe the ratio of gasoline and oil. For compositions with mineral oils it is approximately 34: 1, for semi-synthetics - 42: 1, for purely synthetic - 50: 1. Do not violate these proportions: "oiled" gasoline will not burn out and quickly clog the engine, "not oiled" - will accelerate the wear of its moving parts.

- In terms of viscosity, winter oils include oils marked: SAE-0W / 5W / 10W / 15W / 20W / 25W. For summer - SAE-20/30/40/50/60. For example, SAE 10W-40 is already a multigrade oil (when the mower is operating from spring to autumn, inclusive). Be sure to check with the manufacturer what kind of oil you need.

- Always use high quality gasoline that has been cleaned by the manufacturer.

- The recommended octane number of gasoline is AI-92/95/98. The use of the 76th can lead to a shortage of the engine in terms of power, frequent stalling if you fill, for example, 76th or 80th gasoline.

- If you are not sure about solving problems with a gas mower on your own (which does not pick up speed and often stalls), call a master or contact a service center for repairing motorcycle and garden equipment. Experts are no stranger to doing this job for you.

Observing all these precautions, you will give your mower many years of fruitful work, and yourself - the luxury of well-groomed lawns, comfort and convenience when mowing unnecessary vegetation on your site.

For the reasons why the brushcutter stalls when you press the gas, see the next video.

The comment was sent successfully.