All about coal briquettes

Energy prices and fuel product prices are constantly increasing, leading to a demand for more economical options. This includes such a tool as coal briquettes, which are offered in several versions.

This product does an excellent job with its function, it has a number of positive qualities and advantages that you should familiarize yourself with in detail. We would like to bring to your attention an acquaintance with the varieties of coal briquettes, leading manufacturers, as well as recommendations for operation.

What it is?

Coal briquettes are solid fuel materials that are produced in bricks. At the same time, the tool is offered in more than one size and configuration. In order to bond the particles of the main raw materials and provide strength, specialists use cementitious organic and inorganic additives. This energy carrier is efficient due to its heat transfer parameters and a long burning period, which is significantly different from the characteristics of coal. Throughout the process, the product is able to maintain a constant temperature. It should be noted that the briquettes are so dense that they cannot fall apart, which is a big plus.

Other advantages include the ability to choose any size, shape and even volume. When transporting such fuel material, there is no dust, moreover, it is not subject to destruction and mechanical damage. Hardness and strength are retained for a long time.

Waste can be disposed of, the product has a high energy value, it does not emit a large amount of sulfur. The agent can be fed directly into the firebox without preliminary preparation.

Features of industrial production

The production of briquetted coal is carried out using a special technology on professional equipment. To obtain marketable products, black or brown coal, sometimes coke, is used. It should be noted that the process is quite old, but with the development of technologies on modern equipment, everything can be done much faster and better. During production, roller presses are used. During the process, petroleum bitumen, molasses, tar and other binders are used.

Briquetting goes through several stages. First, specialists dry the feedstock; for this, heated gas can be used. The strength of the original product directly depends on how much moisture is in the original component. It should be noted that the humidity should not exceed 15%. At the next stage, volatile substances are extracted, especially when it comes to low-quality coal, which contains various impurities. During this process, a distillation apparatus or coke oven is used. During industrial production, the product is sorted into fractions, particles up to 6 mm in size are sent to a hopper, where they are mixed, and large ones to a crusher. The latter are crushed to make the briquette as strong as possible.

Coal is mixed with binders, which are heated, the process takes place in a clay mixer. The share of additional components does not exceed 15%, depending on the quality of the main material. Equipment of various designs is used for pressing. In the course of this, the density can double. Then the material is fired in a special conveyor, where it is heated.To make the briquettes strong, petroleum bitumen is added to them. Finally, the products are cooled in a unit with air circulation, which takes about 8 hours. Some businesses use water for cooling.

For the production of briquettes, various equipment is used, which determines the method of forming the final product. The equipment used plays an important role and affects the quality, the units are strikingly different from each other. The stamp press is designed for the release of large batches, it is energy-intensive, but expensive. The molds are filled with coal mass, then pressing takes place under a pressure of 100-120 MPa. As a result, products come in the form of pillows, bricks or tablets.

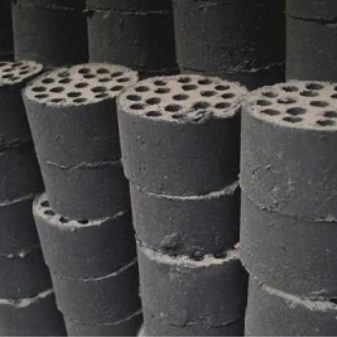

In another case, an extrusion apparatus is used, which has a low cost, therefore, the productivity is reduced. The mixture is fed by means of a screw into the matrix and passes through it. Such briquettes have a cylindrical shape with a hole inside. The characteristics of the equipment affect the size, moisture and other indicators of the product. The production of products for industrial boilers is somewhat different. During the processing of coal and fine coke, water glass or cement is used. This mixture makes the final product as strong as possible, however, the incendiary power is somewhat reduced.

One of the most common methods for producing briquettes is mixing coal dust and sodium salt with other components. At the last stage, certain difficulties may arise, but only if the recipe is not fully worked out.

Views

The varieties of briquettes depend on the material from which they are made, so it is important to understand their differences and characteristics.

Brown

For this, brown coal is used, which is the most affordable at a price. For the manufacture of such briquettes, dust and small particles are used. Thanks to this composition, the calorie content is quite low.

Charcoal

This type of briquettes is made from sawdust and other waste that is left by the wood processing industry. Such raw materials are initially heated and only then pressed under high pressure. During compression, the wood releases lignin, which is an adhesive - as soon as it hardens, the product does not lose its shape and gains high strength. Lignin is a natural material that contains no harmful components. Wood briquettes are characterized by a moisture content of 10%. When burned, a kilogram of raw materials releases about 4400 kcal.

It should be noted that the density of sawdust is different, it all depends on the breed. After combustion, much less ash remains than from brown coal.

Anthracite

This type of coal is considered to be of the highest quality and calories. High-quality briquettes are obtained from such raw materials, with the only drawback being the high cost. It is a useful and efficient fuel material with high flow rates. The main advantage is the resistance of the material to abrasion, it undergoes regeneration and is able to serve for a long time.

When burned, anthracite does not emit much odor or smoke. The composition has a high carbon content, and this is a unique indicator; it also does not contain a lot of sulfur and moisture. Burning off occurs evenly and slowly, this is due to the hardness of the product. Such a tool is used in domestic conditions, it is excellent for operation with boilers made of strong metals.

Popular manufacturers

To select a high-quality fuel material, you first need to get acquainted with the leading manufacturers of such products. There is a wide variety of briquettes on the market, but some of them deserve special attention.

Russian companies are engaged in the production of fuel coal products in large volumes.

- These include Shalash North-West LLC, this company produces products that are suitable for fireplaces and stoves, so they are often chosen by the owners of country cottages. Such briquettes are used in solid fuel heating units with manual loading.

- In the ranking of the best there is company UK "Sakhalinugol"which has been offering its services for a long time. The company's coal meets high standards and is in great demand.

- Novokuznetsk company "Kuzbass TEK" supplies coal fuel with an excellent list of advantages.

- This also includes "Coal Technologies of Siberia" or LLC "Zhariki".

It is safe to say that domestic enterprises can offer quality goods with good characteristics.

It is impossible not to mention the company WEBER, which is engaged in the production of briquettes of the same shape, they are distinguished by a dense texture. The composition includes pressed hardwood coal, corn starch acts as a binder, so the products can be considered natural and safe. One package of material from this manufacturer is enough for several hours of stable heat, which is evenly distributed.

Applications

Briquette coal is a popular fuel product that is constantly used in industrial enterprises and in everyday life. Chemical and metallurgical plants cannot do without such material; power plants and boiler houses can also be attributed here. Briquettes are suitable for use in private houses where there are solid fuel boilers.

As for the use of such fuel material in barbecues, grilling and cooking kebabs or barbecues, this is undesirable, since the smoke will come into contact with food, and this is harmful. Therefore, it is safe to say that briquettes are used exclusively for heating purposes. The briquettes are loaded into the starter tube.

How to ignite?

Everyone faces this question when using coal briquettes for the first time. If you do not know how to properly set fire to this tool, you need to study the instructions and follow the step-by-step recommendations. It is important to note that you can use several methods, each of which has its own characteristics and advantages. You may need a lighter fluid that is sprayed onto the briquettes. After that, it is enough to wait about 5 minutes for the agent to be absorbed, and then set fire to the solid fuel with a long torch. After 15 minutes, the fire will be intense and you can add coal. This method is relatively simple, but the disadvantage is the unpleasant odor that is absorbed into food and clothing. The use of such a liquid is dangerous and every precaution must be taken to prevent injury.

Dry alcohol can be used to light natural charcoal briquettes. To achieve the result, the material is laid out inside the boiler so that a hole remains in the center, where dry alcohol will be located. When the coals are hot enough, fuel can be added. The use of a starter is quite popular, professionals use this method. It is a steel cylinder with a hole and a grate in which the coal is placed. In this case, it should be remembered that liquid must not be poured inside, this can lead to an explosion due to the accumulation of gas. Of course, in any method of lighting briquettes, you must be careful and apply safety measures. Simple rules will help prevent explosions and injuries. If the combustible mixture is not intended for grilling, do not use it. Always have either a fire extinguisher or a bucket of sand close at hand.

When firing up, stay on the leeward side of the boiler or similar equipment. It is important to use protective gloves and a long-handled tool when doing this. When the coals are not needed, they must be covered with abundant ash.Summing up, it is safe to say that different types of coal briquettes have significant advantages over conventional firewood.

Such material is in demand in everyday life and at enterprises where solid fuel boilers are used. This is a high-quality product with a long service life and excellent heat dissipation, and this is the most important thing.

The comment was sent successfully.