How to make a do-it-yourself locksmith vice?

Locksmith's vice is necessary not only in production, where certain products are manufactured, metalworking machines and other factory equipment are repaired. They will also be useful to craftsmen for making all kinds of crafts, in the household, when you need to clamp, bend, straighten a metal profile, drill holes.

Design features

Starting the difficult process of making locksmith yews at home on your own makes practical sense due to the achievement of great advantages. Such a necessary tool:

- useful to everyone who is fond of metalwork - carpentry, plumbing;

- you will need it in an apartment, in a country house, in your house;

- allows you to perform with high precision various works - surface treatment, deburring, drilling, chamfering and more.

A simple device helps to carry out a considerable number of operations - it is convenient and, importantly, safe.

An additional motivation for making a do-it-yourself locksmith vice is cost savings. The finished products that are sold in stores are expensive.

Locksmith vices, installed in various factory workshops, consist of structural cast iron (bed) and tool steel (stop screw, handle, clamping jaws, bolts, nuts and other fasteners). Due to technological and objective difficulties, it is not possible to make the necessary tool for the house from the alloys listed above. Therefore, home craftsmen have to look for an alternative, choosing a design where the use of cast iron is optional.

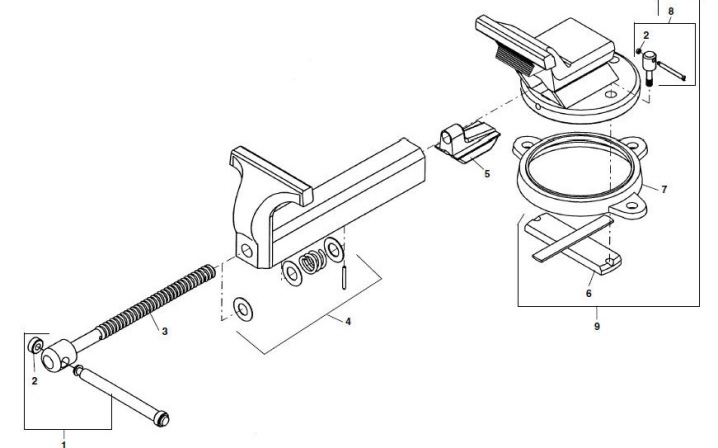

To understand how to make powerful locksmith yews without outside participation for their own needs, a person must know the device of standard samples installed in factories, as well as the specifics of the operation of such devices. Structurally, a locksmith vice consists of several main parts:

- base;

- movable and fixed jaws;

- parallel replaceable plates;

- thrust and clamping screws;

- inner nut;

- a pen.

In popular models of factory vices, a rotation mechanism is provided for a certain number of degrees. For home modifications, it is not of much interest, so craftsmen who make a vice for their own needs do without such a widespread improvement.

The principle of work with a standard vise and made at home is the same.

Before starting the required actions, the foreman with the help of a long handle pulls back the movable mechanism with a replaceable metal plate. Next, he inserts a part, a workpiece into the formed gap and begins to twist the mobile part of the vise until it stops, with a clamp, applying characteristic forces.

Forward / backward adjustment of the vise with a movable jaw is carried out by means of a long screw with an inch or trapezoidal thread, with a coarse pitch that moves sequentially within a fixed nut installed in the body. The rotation of the mechanical device is performed after loosening the clamping screw and is carried out by the master using the necessary efforts.

Some men, in order to save finances and personal time, make miniature locksmith's vice from improvised tools. The most famous version of a simple device used at home is the improvement of pliers. A through hole is drilled in the clamping jaws, a thread is cut. A bolt is screwed into the prepared hole on one side, and a nut is screwed on the other. During operation, the part is inserted between the jaws and clamped by a bolt / nut pair. It is difficult to prove all the advantages of a mobile design, because it is still better to use a stationary vise to achieve comfort and safety.

Required tools

Before starting work, you should carefully think over all the nuances, especially when the time comes to draw up a drawing, because in the project it is necessary to take into account the specifics of the design of yews. For example, it is advisable to provide a small anvil for processing various parts with a hammer, the possibility of achieving a minimum backlash of the lead screw, the option of removable plates on the jaws, as well as a method of attaching to a workbench or other suitable table. And you will also need professional tools.

The main thing to decide is what materials to make locksmith yews. The most suitable options are from a jack, metal sheet and profile (corners, channel, square and others).

A also, devices can be assembled from a hydraulic device if, for example, the unit breaks down or is no longer in use. There are no plastic, plastic or wood parts in the locksmith vise, therefore all parts, except for the stops on the handle, will be made of metal.

To make a small locksmith vice, you will need to prepare a drawing or sketch and a tool in advance:

- electric drill;

- drills of different diameters;

- pencil or felt-tip pen;

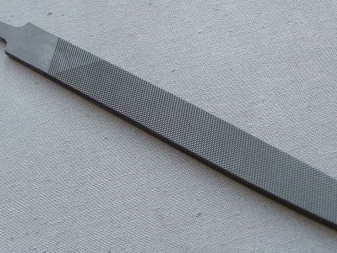

- file;

- tap, knob;

- a set of keys;

- angle grinder;

- ruler;

- welding machine.

Materials required:

- a metal sheet;

- corner, channel or other profile;

- a piece of pipe for a handle or a rod;

- workpiece for a stop screw;

- bolts, washers, nuts;

- dye.

The above list is approximate, because the equipment for making a vice depends on the model.

Schemes and drawings

To make a home vise, you will need to draw a drawing or, in extreme cases, a sketch. And not because the majority of folk craftsmen do this. With a detailed plan, assembling a mechanical device is much easier and faster. And also a correctly drawn drawing will help to avoid common oversights - unnecessary, incorrect drills, typical mistakes when assembling a locksmith's fixture.

In the absence of drawing skills, it makes sense to use the help of an experienced toolmaker or machine operator (turner, milling machine operator) who can not only draw correctly, but also read drawings.

When drawing up a detailed document, it is necessary to indicate the materials used, the dimensions of the blanks, the sequence of actions. For a better understanding of the assembly steps, you can draw several diagrams, number them, and only then start working on creating a locksmith's vice.

In the drawings or sketch, it is necessary to indicate:

- part of the workbench on which the vice will be installed (place for fastening);

- lead screw, fixed nut and thread type;

- flange;

- frame;

- hole for knob and knob;

- pressure jaws;

- fixed part;

- back, front support;

- washers;

- hole locations.

It is not necessary to number every detail. The main condition is to put down the correct dimensions depending on the design of the locksmith's vice.

Manufacturing instruction

It is necessary to start the process of assembling locksmith yews when all the tools and materials are prepared, and the dimensions applied in the drawing are not in doubt. First you need a steel channel, an angle and a metal sheet. The channel will be used as a fixed part in the manufacture of a useful device.

The question regarding the use of a lead screw and nut is solved in one of two proposed ways - to unscrew it from faulty yews or order parts from an experienced turner.

Why is the question of the experience of the machine operator so important? Because, as a rule, a trapezoidal thread is used on the lead screw and in the counterpart, the nut, which must withstand heavy loads. Only a qualified turner with proven practice will be able to cut such a profile without defects. Threading errors can be detected immediately after assembly of the bench vise, when a large backlash is evident, or later in the event of premature wear of the part.

Further, when the screw and nut are made, it is required to cut the channel to size, and attach the mating parts on the workbench. Since the screw will move inside the channel, you will need to cut two plates and characteristic notches from the sheet metal with a grinder. Then the plates are bolted together and welded to one end of the channel. A screw is inserted into the recess with a special neck and screwed into a nut, which is fastened in the inner cavity in the middle part of the channel.

Now you need to make the movable part of the bench vise. Here you should cut 2 corners to size, mark the workpieces with a measuring tool. And also it is necessary to apply a marker on a metal sheet with a marker, as indicated in the drawing, and cut out the required plates. Prepared corners before welding must be attached to the structure and see if everything is done correctly.

Weld the corners and the cut profile from a sheet of metal in such a way that a part similar to the letter "P" is obtained.

Place the blank in the form of a characteristic letter "P" on top of the previously prepared profile. If everything is as it should be, remove the product and drill 6 holes along the edges for inserting fasteners - bolts. In order to strengthen the structure, make the same holes in the metal sheet. That is, the result will be the following: the sheet will be laid on the workbench, followed by the part of the letter "P", and in the resulting space - the finished channel.

The next step is to cut the sponges out of the corner. For these purposes, an angle grinder is also used. The contour can be selected in the shape of a trapezoid. Try on the finished parts for the main product. Interchangeable plates are manufactured separately and subsequently bolted to the jaws in the pre-drilled holes. If all goes well, weld on the sponges according to the drawing.

The last step is choosing a metal handle. It is made from a hollow tube or thick rod. When ordering a simple part from a turner, you can ask the machine operator to grind special necks on both sides during operation in order to be able to make characteristic stops from rubber rings. Then the handle of the yew for the house will not fall out of the hole when the movable jaw is rotated. Homemade vise can be installed on a workbench and finally bolted.

Recommendations

If you don't have enough experience in such work, you need to think over everything to the smallest detail. After preparing the drawing, analyze the assembly steps in your head. Buy metal products with a stock, because some parts in the process of work may be damaged. Purchase a large number of different bolts, as well as drills of different diameters.

After drilling and other work, clean every detail with a file so that there are no burrs and sharp edges. When tapping threads, lubricate the inner surface with machine oil. If you have no experience with a welding machine, it is better to invite an assistant who will reliably weld the parts. A hexagon can be used to make the thrust nut and screw.

How to make a do-it-yourself locksmith vice, see below.

The comment was sent successfully.