What is a precision machine vise and what is it for?

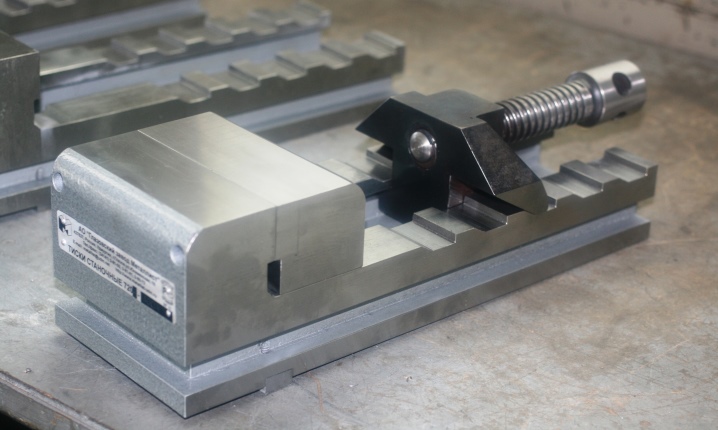

Turning work, especially when machining small parts, may require high precision. It is for these purposes that a precision vice is used, which allows you to very reliably hold the workpiece to be processed. This type of vice has a perfectly polished surface of the clamping jaws and a smooth movement of the locking mechanism, which ensures the most accurate and precise clamping of even tiny parts.

What it is?

Precision machines are a device that allows you to ensure the most accurate position of the part and its minimum deviation relative to the jaws.

On many models, the jaws can be replaced and the stroke adjusted depending on the type of device. Classic precision vices have a screw that, when the handle moves, is screwed into them and adjusts the distance between the jaws.

The advantages of these machines include:

- quick installation of the vice on the working surface;

- 100% alignment of equipment relative to the required plane;

- high positioning accuracy of the part, as well as its minimum displacement;

- guides of increased hardness;

- constant clamping force, without loosening;

- increasing the speed of cutting and material removal.

Precision vices are widely used not only in large industries, but also in small companies engaged in milling and other processing of metal, wood and other materials.

Types and purpose

Precision machine tools come in several varieties.

- Stationary (non-rotating). They make it possible to fix the part in relation to the jaws only at right angles.

- Multi-axis. They have the ability to rotate along different coordinate axes.

- Sinus. It is possible to process the part at any angle necessary for the convenience of work.

The precision vise has a variety of drive designs and is also equipped with extra strong hardened metal jaws. The equipment is used for milling, grinding and other very precise work. Stationary (non-rotating) precision vices necessarily complement the operations that are performed on CNC machines and processing devices.

Criterias of choice

When choosing the optimal vise model, several important points should be clarified.

- The dimensions of the parts that are planned to be processed using the machine. This indicator directly affects the size of the precision vise. However, as professionals note, large machines are more practical than small ones. They break less often and serve for a very long time.

- The presence of ball bearings. This important detail allows the vise to be tightened much more comfortably and reduces the amount of physical force used.

- The presence of a lifting mechanism. This is a very convenient function that allows you to perform any work at a given height.

- Correspondence of the main parameters of the precision vise and the surface on which they are planned to be installed.

In order to get the most out of the precision vise, models with replaceable clamping plates should be preferred. This will allow you to process a variety of materials, as well as quickly change sponges if necessary.

It is also important to consider how the screw will be insulated. This is very important in order to minimize the contact of the vise with dust and metal shavings, and thus increase the life of the equipment.

Guided by these recommendations, you can choose the best option for precision vise, which means that it will be possible not only to simplify the work and reduce the physical load on the workers, but also to expand the production possibilities.

All about the vice of machine tool precision MVN-150, see the following video.

The comment was sent successfully.