Features and types of vise jaws

Vise jaws are made from different materials. In existing vise models, they have different sizes, widths, properties and scope of use. We will consider what replaceable sponges are intended for, their varieties, how and from what raw materials they are made with our own hands.

What it is?

The jaws are the working parts of the vice designed to fix the workpiece. It is they who are in contact with the workpiece, and the accuracy of basing the workpiece and the quality of its surface layer depend on their properties.

Therefore, certain requirements are imposed on the sponges:

- high coefficient of adhesion to the workpiece material;

- the clamping force must correspond to the strength of the workpiece;

- positioning accuracy of the workpiece (especially for machine vice);

- reliability and durability.

The clamping force of the workpiece can be 15–55 kN. And to increase it, notches are made on the lips. Therefore, if used improperly, dents and scratches may remain on the workpiece.

To prevent this from happening, the vice is supplied with a set of interchangeable linings designed to work with different materials of the part. This is especially true of locksmith models, in which both soft aluminum blanks and hard steel ones are fixed.

Joiner's and some other vise models are usually not equipped with replaceable linings.

Varieties

There are no fundamental differences in different designs of the vice. The number of jaws may differ (there may be additional ones), as well as their configuration (there are corner models, there are chain vices for pipes, and there are also special ones).

All types of vise have fixed jaws and movable ones.

- Immobile. They are usually manufactured in one piece with the bed. They often have a small anvil that expands technological capabilities. Some large locksmith models have a turntable on the bed.

- Movable. The mother nut is welded to them, into which the lead screw is screwed. When it rotates, the sponge moves, while in different models it is realized in different ways.

- Stools. In them, the movable jaw is fixed on a hinge and moves around the circumference, like a forceps (at a small angle). Now they are practically not used.

- Parallel. In any position of the vise, they are strictly parallel to each other. It is now the most common type of clamps.

Parallel ones are divided into 2 types:

- with one movable jaw;

- self-centering.

In the latter version, they both have a drive, and the clamped part is exactly in the center of the body. Such designs are used in mechanical engineering to perform operations of the same type. For locksmith tasks, their purchase is impractical.

One of the most important parts is replaceable pads. For fixing different workpieces, the material of their manufacture is different. This could be:

- wood;

- plastic;

- solid rubber;

- soft metal (copper, aluminum and others);

- hardened steel.

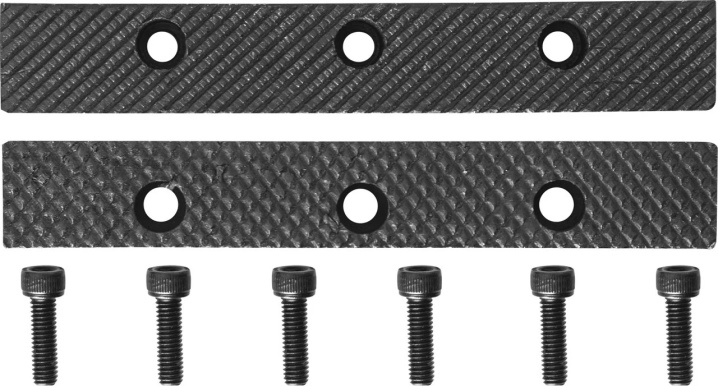

Also the sponges differ notch. It happens:

- pyramidal with a sharp top;

- pyramidal with a flat top;

- in the form of a grid.

The general rules for the selection of cover plates are as follows:

- for solid workpieces soft sponges are needed - if you use hard ones, the part will scroll, and this will lead to marriage, and even to an accident;

- for parts made of soft materials you need hard jaws with notches - this will prevent the workpiece from slipping and ensure high accuracy of installation.

It should be borne in mind that the accuracy of locating the workpiece in soft jaws will be lower than in hard ones. This is caused by the deformation of the linings. But this is true for precision clamps on CNC machines. This does not really matter for a conventional locksmith vice, since the processing is done manually.

Please note that the hardness of the wooden sponges depends on the orientation of the fibers. If they are perpendicular to the work plane, stiffness is high, and if parallel, it is low. This is important to consider when making your own.

Replaceable jaws can be manufactured without complicated equipment... But first you need to decide on the size.

Dimensions (edit)

Vise is a standardized piece of equipment that manufactured in accordance with GOST. Several standards are provided for them:

- small vice: jaw height - 50 mm, maximum stroke - 80 mm;

- medium: height - 180 mm, working stroke is 120-125 mm;

- large: height - 220 mm, the size of the stroke is 140-160 mm.

Chair models have similar characteristics. In them, the height of the jaws is in the range of 65–75 mm, and the length of the working stroke is 120–150 mm and more.

The protrusion of the linings from the grooves should be 2-3 mm (for large locksmith vices). In more compact specimens, it may be smaller.

There are models with other clamping bar sizes. But if for some reason they do not fit, then the overlays can be made by yourself.

How to do it yourself?

First, decide on material... We have already talked about how to choose it correctly. You should not limit yourself, you can make several pairs of clamping bars "at a time" and change them as needed.

Further dismantle the old linings... This work is very laborious, for sure the bolts are rusted, and it will not be possible to remove the linings just like that. Then they need to be cut down with a grinder with a cut-off wheel. But be prepared that you will not be able to unscrew the rest of the bolts. Then they need to be sanded, and then new holes are drilled and threaded into them.

Next, we start manufacturing. Using simple tools, you can make good wood trims. In this case, they will be fixed not with screws, but with magnets, and you will not need to remove the old sponges.

The main idea is to make easily removable sponges. They are attached to the magnets with a bracket made of sheet metal 1–2 mm thick. The work consists in performing a certain sequence of steps.

- Take 2 identical wooden blocks. Their thickness must be sufficient so that a screw can be screwed into the end. The length and width are determined by the dimensions of the vise.

- Attach a magnet to the top of each sponge. Find a position where they hold with the greatest strength.

- Clamp both of our new pads in a vice.

- Make a template out of paper by attaching it to the pad and magnet. Make the necessary folds. Next, cut out the resulting shape, straighten and transfer the contours to the metal.

- Shape the metal into the desired shape. To do this, attach it to the pad and magnet and make bends. Then remove any burrs and sharp edges.

- Fasten the brackets to our wood trim with 2 screws. To do this, you need to drill holes.

- Do the same to make another sponge.

The magnet does not need to be attached to the bracket at all - he will keep on his own. But if you need more reliability, then it can be attached with screws or glue. Great strength is not required since the fastening forces do not act on the joint.

The advantages of such self-made sponges are ease of execution and low cost, as well as the fact that the linings are quickly removed and installed. The disadvantage is that the size of the working stroke of the vice is reduced.

The main requirement is the overlays must be strictly parallel.

You can do it yourself metal sponges, but you can't do without a snap. Use standard mounts. But make sure the mounting slots are straight.If this is not the case, they need to be leveled with a router, dremel or sanding.

New clamping bars can be made from old turning tools.

- Determine the required dimensions with a caliper or internal gauge.

- Use them to make 2 metal bars. These will be the sponges.

- Drill 2 holes each. They should clearly coincide with the installation ones and lie strictly perpendicular to the clamping surface. This is the most crucial moment. To ensure their diameter can be made slightly larger.

- Make indentations in the holes for countersunk bolts. Better counterbore so that the bottom turns out to be flat and not conical.

- Apply risks with a dremel or grinder with a thin circle.

- Temper the sponges and then release them. The temperature depends on the grade of the material.

- Fasten the pads in a vise. If they "sit" unevenly, adjust the dimensions as needed. After hardening, this can only be done by grinding.

Pyramidal sponges can be made from a flat file. Before work, annealing must be carried out to make the material softer. Further, the technique is no different.

In the next video, you can watch the process of creating do-it-yourself vise jaws.

The comment was sent successfully.