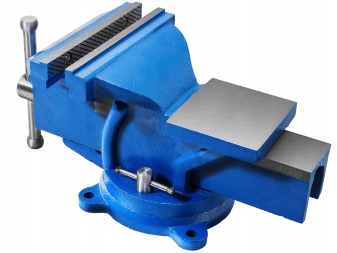

How to make a vice from a channel with your own hands?

Homemade vise - a worthy replacement for purchased ones. Quality vices are made from high quality tool steel. They are durable - they will work for tens of years. Heavy "homemade", made with his own hand from a simpler alloy steel, will cope with everyday tasks no worse than an industrial tool.

Peculiarities

Industrial vices - especially carpentry ones - come close in their power (applied downforce to the parts) to a vertical press. The most common replacement for industrial locksmith vices is a vice based on a T-shaped or simple angle profile, made on the basis of a piece of channel.

They are made by anyone in a garage environment - the mechanism is quite simple, and if necessary, they can be converted into a mechanical jack.

The base of the vice is stationary fixed on the workbench bed with an anvil along which the movable part moves. She is driven bolted axle, driven by Gates - the crossbar inserted into lead screw endfacing the working master.

Required materials and tools

To make a do-it-yourself locksmith vice you will need:

- channel;

- bolts with nuts not thinner than standard size M10;

- two corner or one tee profile;

- steel plate not thinner than 5 mm;

- a screw (stud) of a standard size larger than M15 and several nuts for it;

- steel bar not thinner than 1 cm.

It is preferable to connect parts of the future vice welded way. In addition to an electric welding machine (preferably an inverter device) and electrodes, you will need:

- grinder with a set of cutting and grinding discs for metal;

- square (right angle ruler);

- construction marker or pencil;

- ruler-tape measure;

- drill with a set of drills for metal;

- a pair of adjustable wrenches (for nuts and bolts with a maximum size of the rotating part of 25-30 mm).

Don't skimp on the size and thickness of the parts.

Manufacturing instruction

As a drawing - the simplest scheme manufacture of joinery vice. Referring to the drawing, do the following.

- Mark and cut the metal plate, channel and corner, guided by the dimensions according to the diagram. The channel and the angle are the same in length, the plate is 1.5 times longer.

- Saw off an additional segment from the metal sheet that matches the width and height of the channel. Weld it from one of the ends of the channel.

- Using a grinder, make a longitudinal cut in the middle of the welded piece of the plate under the running pin. The diameter of the stud may be less than tenths or hundredths of a millimeter than the kerf width - this will allow the screw to rotate freely.

- Drill an eyelet under the gate at one end of the lead screw. Insert a bar into it.

- Weld a nut or some washers to both ends of the bar to keep the bar from falling out. Now you can turn the screw with the gate - just like in a conventional industrial vise.

- After making sure that the gate is working properly, weld two lock nuts on the inside of the channel, placing them close to each other. The nuts are located along the longitudinal centerline of the channel.

- Insert the lead screw and turn it by screwing it into the nuts. Its movement should be easy - this is an indicator that the nuts are welded correctly.

The movable part of the vice ready. To make a bed (fixed part), do the following.

- Weld the corners to the larger steel plate (previously cut off), positioning them so that the channel can move along them easily. Both the corners and the channel are located exactly in the middle of the base plate (steel plate).

- Drill in exactly the same metal plate that is welded to the channel, a hole for the lead screw. It should be in the middle.

- Weld the plate to the corners on the other side of the vise where the lead screw will pass.

- Move the screw to the plate. When its end (should be with a margin of 10 or more centimeters) is threaded into the hole, screw the nut exactly the same as the locking nut. Scroll it until the channel is completely pushed between the corners and rests against the end plate.

- After making sure that the nut is screwed in all the way, weld it to the plate. Try not to deviate from the center line of the channel, the lead screw.

- Check that the lead screw turns without noticeable effort and that the structure does not wobble. The base of the vice - the movable and fixed parts - are ready.

To install the clamping planes, follow these steps.

- Cut equal parts from the remaining plate. It is advisable to use 2-3 on each side - on the moving and stationary parts. This will give the vice an extra margin of safety and downforce.

- Weld the cut pieces of the plate together. For example, you will have a triple thickness pressure jaw (15mm steel). The thicker, the more squeezing, clamping will give out a vice. But do not overdo it - a dozen or more plates will noticeably increase the weight of the vice, and the extra steel will do nothing in the work.

- Place the plates parallel to the workbench, which will eventually hold the vise. Before welding, you can fix them with clamps, setting the horizontal level. The vise must be firmly positioned on the workbench, without distortion. Weld one plate to the movable part and the other to the stationary part.

- Make sure that when the lead screw is fully screwed in, the plates close together without creating gaps.

The vise is ready. Lubricate threaded connections lithol or grease - this will eliminate premature wear of the lead screw and nuts. Drill on base plate (plate) vise six holes (3 each on the left and right) - for M10 bolts. Referring to them, drill the same holes in the workbench countertop. Secure the vise to the workbench using M-10 nuts with spring washers.

The homemade tool is completely ready to go. Its dimensions when folded are about 20x20 cm (space occupied on the workbench), and in height (without a gate, taking into account sponges) they reach 12 cm.

Conclusion

Workbench vise Is a fairly simple tool to be easily replicated. By choosing a sufficiently thick screw and bolts, you will provide a decent margin of safety. This tool will serve you a lifetime. Vise with vertical jaws... And if you take even more powerful parts, you get a manual press.

Next, watch the video with a master class on making a vice from a channel with your own hands.

The comment was sent successfully.