All about the installation of decking

Decking is a popular and practical material that is in great demand. Today, finishing from such a coating can be found very often. A high-quality decking board can be installed not only by specialists, but also by home craftsmen who have decided to lay it on their own.

Basic rules for laying

If you decide to start installing a decking, it is advisable to familiarize yourself with the basic rules related to these works.

- The surface where the boards will be laid further must be perfectly flat, straight, strong and reliable... Otherwise, the structure will not last long.

- Lags in no case are allowed to be mounted simply in the ground on the site... These parts should also not remain in the water, since they will quickly begin to deteriorate and collapse.

- High-quality flooring will always have underneath drainage or gutter.

- Decking can be done by forming a slope towards the drain, but not less than 1%. More precisely, 1 cm per linear meter.

- There must be unobstructed air circulation. This will remove all excess moisture quickly and easily. This will prevent the formation of mold or mildew.

- The screws that you plan to use for laying the board must have anti-corrosion protective coating.

- After completing all the installation work related to laying the decking, the coating is required wash at least 2 times with high pressure water.

Tools and materials

The process of installing terrace boards will not do without the use of special tools and all the necessary materials. It is necessary to collect such components well in advance of the start of installation work. In order to install decking boards with high quality and trouble-free, the master must stock up on the following tools:

- drill or screwdriver;

- construction level (laser and bubble devices are the most practical and convenient to use);

- a set of different screwdrivers;

- tape measure and pencil;

- corners;

- special file for working with wood.

From the materials, the master will need the following:

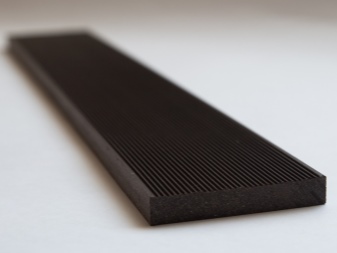

- the deck board itself is of a suitable size;

- supporting mounting lugs (aluminum copies are suitable);

- end strips;

- a sufficient number of screws;

- stubs;

- intermediate and initial brackets (otherwise these components are called cleats);

- starting mounting clip;

- adjustable supports.

It is recommended to concentrate all the necessary components in one place so that during the work the master has everything at hand. Then you do not have to spend extra time looking for the desired item, because it will already be there. All the tools that will be used for the installation of the decking must be of high quality, serviceable.

If such devices turn out to be faulty or simply broken, then it will be extremely difficult to work with them, and it will be impossible to get good results.

How to prepare the surface?

Before proceeding with the installation of decking, it is important to correctly prepare the surface that will serve as the basis. It must be even, without potholes and drops. There are many options for what to lay the decking, but in most cases concrete mortar is chosen for this. It should be not only dry, but also perfectly flat and reliable, prepared according to technology.

If the flooring is planned to be laid directly on the ground base, then even with such a decision, the master must take care of its reliability and level of evenness. The ground on which the boards will be mounted must be strong enough.

To meet these simple requirements, the base in question can be pre-laid with concrete elements, paving slabs, blocks or other similar components that can be laid out under the decking.

Before installing the boards, the top layer of soil is completely removed. After that, you need to form a cushion of sand and gravel.

The best will be a base made of concrete. It is not allowed to mount boards on open ground just like that.

Before proceeding with the installation of the boards, it is advisable to make sure that no water accumulates on the base. The lags are required to be fixed along the drain. You can do a little differently: leave a small gap between the lags, thanks to which the liquid will drain unhindered.

Lags are laid out on the basis, fixing them with dowels. Small gaps should be left between the indicated elements, which should not exceed the mark of 35-45 cm. If the board has a thickness parameter of 19-20 mm, then the gap between the lags can be only 40 cm.If the laid material has a more impressive thickness, then it is permissible to leave gaps of 60 cm. evenness, then we allow the installation of adjustable lags. When installing them, it is required to make a slope at a small angle. Due to this, excess water can easily drain off.

Laying methods

Decking, like any other material of this type, must be laid in accordance with a number of rules. How exactly to mount such a coating depends on the base on which it is laid. For example, on concrete and wood, the decking must be installed in different ways. Let's take a closer look at what methods of installation exist, and what actions they provide.

On concrete

If it is decided to lay the board on a base poured from concrete solution, then it is very important to take into account that the master should first take care of the installation of waterproofing. It is not necessary to carry out work without the use of waterproofing. The boards themselves begin to be installed, moving from the walls, making an indent of 0.8 cm.

- It is necessary to put a starting WPC decking board. The “spiked” side of the part must face the wall. Further, the fixation is carried out directly by means of fasteners. When fastening, it is recommended to adhere to a step of 30-35 cm.

- The side of the deck board, which is closer to the wall, should be well pressed down to the concrete base using the plinth. It is recommended to use a practical resin part. More often choose a plinth made of plastic.

- The next flooring component will need to spike into the inside of the next plank. In this case, it is required to maintain a distance of 0.2 cm. The fixed component will need to be fixed with special dowel-nails.

- It will be necessary to lay all other terrace boards in the same way.... If docking is carried out along the length of the finishing flooring with a length less than 400 cm, then the elements will need to be fitted to each other as tightly as possible. When adjusting longer boards, you need to leave a small gap of 0.45 cm. Sections of joints of different terrace boards should in no case coincide perfectly. The smallest distance allowed between the docking areas is 20-25 cm.

- The edge sections of the new wooden flooring are allowed to be additionally fixed. To ensure reliable and high-quality fastening, aluminum corners with dimensions of 30x30 mm are suitable. The open edge, where the "thorn" is located, should be fixed with a screw, the head of which is "hidden" by means of a chamfer. The edge is covered with an aluminum corner.

It is quite difficult to correctly lay a decking board on a concrete base, but it is possible. The main thing is to act in stages, not to rush.

It is important to strictly follow the technology of laying such material. Then the master can expect to get excellent results.

On the tree

The type of material under consideration is mounted not only on concrete, but also on wooden bases. This is often the floor on the veranda or patio around the pool. Such installation work can also be carried out independently without calling a team of experienced craftsmen. If for further installation of decking from a decking board, a lathing made of wood or a solid "deaf" flooring has already been prepared, then for fixing decking planks it is best to use high quality galvanized screws.

If the basis is not a continuous version, then it is recommended to pre-treat the board with antiseptic solutions that perform a protective function. After applying antiseptics, it is also advisable to paint the boards in a suitable color. This will make the material not only more attractive, but also more durable. The process of installing terrace boards on a wooden base is carried out leaving standard gaps of 10-15 cm.

The very technology of fixing the considered elements of an attractive flooring turns out to be exactly the same as in the case of a concrete base.

On metal

Wood and concrete are not all options for foundations on which decking boards can be installed. Often, such a flooring is attached to a metal frame. To lay the deck board on a sturdy welded frame, you will need the following steps.

- First, you need a competent laying of the lag. For this, aluminum parts are best suited. Of course, you can use lags from WPC or wood, but in the end, their installation may be less convenient.

- Aluminum logs must be laid, leaving gaps of 30-50 cm. It all depends on the type and parameter of the thickness of the decking. We must not forget that the logs need to be laid not on the metal base itself in the form of a frame, but on rubber or polymer pads that were previously placed. This simple technique avoids unnecessary contact between steel and aluminum. In addition, expansion of the metals is effectively compensated for by the additional padding.

- The lags must be fastened as tightly as possible.... For such purposes, high-quality self-tapping screws or anchor bolts are suitable. First, the terminal is fixed, after which the starting terrace board is inserted. It will need to be fixed on the other side by means of the main terminals. A through-type fixation is also suitable, when the first board is simply screwed on with self-tapping screws. Next, the next board is laid and fastened, and so on until the end.

- If the base itself, on the surface of which the terrace board is laid, turned out to be raised, and in the future it is not planned to blindly close the underground space, boards are allowed to be installed side by side.

- If the gap in the lower part is not able to provide the proper level of ventilation, it is advisable to maintain gaps of 3-5 mm between the floorboards.

- After completing the installation of all terrace boards on a metal base, it will remain to properly seal the edges of materials using special edge strips or F-profile... After that, the flooring made of high-quality decking can be considered ready for use.

Features of facade decoration

Terrace boards are purchased with enviable frequency in order to decorate facades beautifully. The facing material in question is installed on the indicated bases according to a certain scheme.To fix the boards on the facade, you can call specialists, or you can do all the work yourself. We will analyze the step-by-step instructions on how to properly mount the board in question on the facade base.

- This type of decking is also called facade.... The starting bar is attached to the crate, pre-assembled on the facade, by means of self-tapping screws directly along the planes located outside. After that, the fastener will need to be installed in the end of the strip. This should be done so that the second bent plane of the material begins to abut against the plane of the batten lath.

- Next, using a nail, the fastener is attached directly to the end of the facade strip.

- Another nail need to be driven into the crate.

- The second board must be installed on top of the first, making a clamp to the base - the crate.

- The upper bar is driven into the spike of the fastener. To do this, it is best to use a mallet and a small block of wood. Impacts should be made as close as possible to the areas where the frame battens are located.

All facade boards are installed according to this principle. The diagram is simple and straightforward. In most cases, a similar installation method is used for ventilated facades. In the gap that remains between the cladding and the wall, a small free space is always left. From it, damp air vapors that penetrate into the premises of the building are discharged upstairs, without remaining on the wooden facing materials.

Often, thermal insulation materials are laid under the decking installed on the facade.

Common mistakes

When self-assembling a decking board, the master can make many different mistakes. It is better to know about them in advance in order to try to get around. Let's consider what mistakes are the most common when installing decking on certain bases.

- Most often, craftsmen do not observe the required gaps when laying decking. Such gaps should be left between the planks themselves and between the planks and walls. Having made such a mistake, there is a very high risk that a new and beautiful floor will soon begin to deform, losing its former attractiveness. As soon as external defects begin to appear, twisting of hardware will be added to them.

- An improperly equipped water drain is also a common mistake. Often, novice masters completely forget about him. As a result of such an omission, terrace boards soon begin to rot due to excess liquid accumulated in the logs.

- A mistake is the lack of preparation of the base on which the laying of terrace boards is planned.... These materials can only be placed on well-prepared bases, and it is completely pointless to simply lay them on the ground and wait for good results.

- Avoid tightening all fasteners too tightly when laying decking.... This is one of the most common mistakes to watch out for.

- A correct joint must be provided between the decking boards. If the floor is assembled without observing the correct joining between the parts, it may begin to deform.

- Many craftsmen forget that wooden logs that were used for laying the future flooring must be treated with antiseptic compounds. If the structure is based on metal lags, then they will need to be smeared with anti-corrosion solutions.

If you forget about such procedures, the materials in the base will soon begin to deteriorate and deteriorate.

Helpful hints and tips

Before you start laying the decking board yourself, it makes sense to familiarize yourself with various useful tips and tricks related to carrying out these works. Perhaps it is just simple tips that will allow you not to face serious problems and find answers to your questions.

- It is not as easy to assemble terrace boards on your own as it might seem. In this matter, it is very important to adhere to the correct technique, to act competently. If the master doubts his skills and is afraid to spoil not the cheapest material, then it is better to refuse from “homemade products” and call specialists.

- The master should be aware that the kleimers are exposed absolutely on all lags. If you do not follow this rule, then the subsequently laid floor from the board will simply begin to bend.

- It is recommended to make sure that the clamps clearly enter the grooves of the decking.... This provides a more reliable and strong fastening, as well as a mandatory gap between the individual boards.

- It is important to ensure that the decking does not remain flooded with water for more than 4 days. This requirement is especially important if the material was used to decorate the area around the pool.

- Decking, like any other facing material, must be kept clean... To clean and free the boards from dirt, do not use metal sponges, scrapers that look like blunt knives, or spatulas. Better to take a regular piece of cotton or microfiber cloth. Such products will not harm the boards, they will not leave scratches or chips on them.

- If certain defects appear on the terrace board, for example, traces of cigarettes, then you can get rid of them with sandpaper.

- To wash your decking, it is recommended to use only regular, clean, running water. Only non-abrasive detergents are suitable, which do not contain aggressive acids.

- If you need to choose the ideal boards for cladding the area around the pool or facade base, it is worth giving preference to decking made of hardwood... The coatings are more practical and durable.

- Decking can be composite or made of pure solid wood... Both materials selected for future finishing works must be of high quality. It is recommended to choose branded products that are free from defects or damage. Low-quality boards will not last long, and they will look frankly cheap.

- Choose decking boards that are of the right size and thickness. If necessary, the excess can be cut or sawed using special wood tools.

- If you have prepared the foundation for future installation work, then a set of logs and strips can be delivered to the site. These components must lie down a little in order to undergo the necessary acclimatization process.

- If the terrace board is installed inside a heated room, then it is allowed to cover it with high-quality parquet varnish.... It must be applied in several layers (at least 2).

- The deck board can be combined with underfloor heating.

- Handle wood materials with care... Try not to drop or scratch your brand new deck boards. They must be installed strictly according to the instructions.

- The technological gap, which must be foreseen at the stage of installation of the lag, must be at least 2 cm... It is in this gap that gutters or curbs will be based, so you cannot forget about such components.

- If you are looking for a deck board for a place where a lot of people are moving, then it is advisable to give preference specimens with high density. Most often, it is these coatings that are mounted in areas around gazebos, terraces or residential buildings.

- If you decide to install insulation under the cladding, mounted on the facade base, then you can attach by means of an adhesive solution, as well as dowels-fungi with a metal rod.

In the next video, you will get acquainted with the rules for installing decking from natural materials.

The comment was sent successfully.