Thermal drive for greenhouses: features and benefits of operation

Life in the organic and eco style forces modern craftsmen to resort to the most comfortable arrangement of their land plots in order to produce more high-quality products. Often, everything that is planted on a personal plot is used for itself, rarely any modern farmer with a small garden arranges the cultivation of vegetables, fruits and berries on an industrial scale. However, ordinary summer residents and gardeners have a lot to learn from professional farmers. For example, automation of various processes in greenhouses.

The need for ventilation

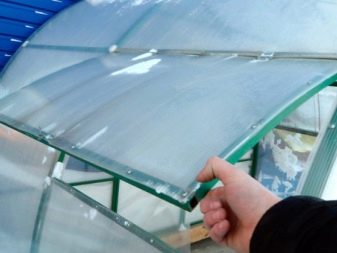

All residents of apartment buildings know that you can get fresh vegetables in winter or early spring only at the store. But those who have at their disposal at least a small piece of land can arrange a vegetable feast for themselves during cold weather and poor harvests. For these purposes, greenhouses are often set up in vegetable gardens. Such outbuildings can be made of various materials: from dense industrial film to heavy glass. The most popular today are polycarbonate greenhouses.

The main principle of the greenhouse is to create the most comfortable conditions for growing crops.

Several factors contribute to this.

- Maintaining the temperature. For the full functioning of the greenhouse, there must be at least 22-24 degrees of heat inside.

- Optimum air humidity. This parameter is developed for each individual plant. But there is also a certain norm, which ranges from 88% to 96%.

- Airing. The last point is a combination of the two previous ones.

In order to normalize the necessary temperature and humidity in the greenhouse, it is necessary to arrange air baths for the plants. Of course, you can do it yourself. In the morning - opening doors or windows, and closing them in the evening. This is what they have done before. Today, agricultural technological progress has made it possible to invent devices for automatically opening and closing windows in greenhouses.

It should be understood that standard plant drafting techniques are not acceptable. From too sharp a drop in temperature or humidity level, deterioration of the state of the culture and its death can occur. If in film greenhouses there is a variant of self-ventilation (due to the insufficient tightness of such structures), then glass and polycarbonate buildings are in great need of automatic ventilation.

In addition to monitoring these indicators, there is also a risk of developing pathogenic bacteria and microorganisms.negatively affecting the growth of vegetables and fruits. Many insects also prefer warm and humid locations for their deployment. Periodic air baths in greenhouses will bring them discomfort. This way, no one will encroach on your future harvest.

In order not to worry and not to run every half hour or hour to the greenhouse, checking all the indicators, experts in the field of agriculture advise to purchase and install thermal drives. What it is and how it works, let's figure it out further.

Features and benefits of application

In fact, a thermal actuator is an automatic closer, which is activated by an increase in the room temperature. Relatively speaking, when the plants get too hot, the window opens.

This auto-ventilator has a number of pleasant advantages.

- There is no need for constant temperature control in the greenhouse.

- There is no need to conduct electricity for it to work.

- You can buy a thermal actuator in many gardening stores and departments of building hypermarkets at an affordable price. You can also make it yourself from almost improvised means.

Before proceeding with the choice of one or another automation for ventilating the greenhouse, pay attention to the features of the installation and use of this tool.

The first and basic rule is to pay attention to the fact that the effort to open and close windows and doors should not exceed 5 kg.

The second nuance is the selection of the required place where the ventilator will be located. Since it consists of two parts and has two fasteners, one of them must be attached to the wall of the greenhouse, and the other to a window or door. In this case, you need to check how convenient and simple it will be to mount one of the mounts on the wall of the structure.

The third feature of greenhouse thermal drives is that the inner cavity of the working cylinder is always filled with liquid. This circumstance controls the opening and closing of windows and doors. Therefore, manufacturers do not advise disassembling the design of the device, so as not to harm. Full functioning is possible only with a certain amount of liquid.

The nice thing is that self-opening windows and doors can be applied to any structure: from standard foil to durable polycarbonate structures. Even in a dome greenhouse, an automatic thermal drive will be appropriate.

Characteristics and working principle

Regardless of which type of thermal drive is used, its main function is to automatically ventilate if the temperature exceeds the maximum permissible threshold. When this indicator decreases and becomes optimal, the drive is triggered to close the window or door.

There are only two main operating devices in the thermal drive: temperature sensor and the mechanism that sets it in motion. The design and location of these components can be very diverse. Also, this device can be completed with door closers and special locks, which ensures tight closure.

Automatic machines for doors and vents in a greenhouse are usually divided into types according to their mechanism of action.

- Volatile. It is an electric drive that is driven by a motor. To turn it on, there is a special controller in the device that reacts to the readings of the temperature sensor. A huge advantage of this type of thermal drive is the ability to program it according to your individual parameters. And the biggest drawback is its volatility. Power outages may occur when you do not expect them at all, for example, at night. Firstly, a centralized power outage can lead to a malfunction in the program of this type of thermal drive, and secondly, plants can undergo both freezing (if the autofilter remained open after turning off the light) and overheating (if ventilation did not happen at the set time).

- Bimetallic. They are arranged in such a way that plates of different metals, interconnected in a certain configuration, react to heating in different ways: one increases in size, the other decreases. This skew makes it easy to open the window for ventilation in the greenhouse. The same action occurs in the reverse order. You can enjoy the simplicity and autonomy of the mechanism in this system.The disorder can provide the fact that there is not enough power to open a window or door.

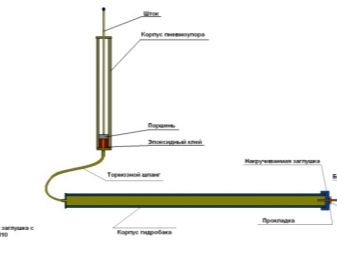

- Pneumatic. Today these are the most common piston thermal drive systems. They act on the basis of the supply of heated air to the actuator piston. This happens as follows: the sealed container heats up and the air from it (increased, expanded) is transferred through the tube to the piston. The latter sets the entire mechanism in motion. The only drawback of such a system is the increased complexity of its independent execution. But some folk craftsmen were able to think of this. Otherwise, there are practically no complaints about pneumatic thermal drives.

- Hydraulic. The simplest and also often used in private garden farms. Two communicating vessels are taken as a basis. Liquid is transferred from one to another by changing the air pressure during heating and cooling. The advantage of the system lies in its high power, complete energy independence and ease of self-assembly from improvised means.

Domestic thermal actuators of various types are receiving very good reviews today. To establish at least one of them will not be difficult even for a person who does not understand anything about it. And the pleasant cost of systems for automatic ventilation of greenhouse structures pleases both the eye and the wallet of thrifty owners.

If you decide to make a thermal actuator yourself, use the step-by-step instructions for this process. You will have to make not only efforts, but also diligence and maximum attention to all details in order to achieve the desired result.

How and from what to make yourself: options

The plus of creating a thermal actuator with your own hands is the possibility of using scrap materials. It is enough just to prepare all the details necessary for this.

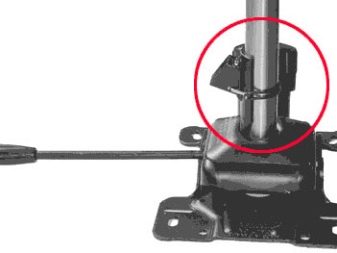

An office chair-chair is a very convenient and simple tool for making an auto-thermal drive. How often, while working at the computer, have you raised and lowered the seat to the required level? This was possible thanks to the gas lift. It is sometimes also called a lift cylinder.

To make a do-it-yourself thermal drive for a greenhouse from this part of an office chair, do such manipulations with it.

- The cylinder consists of two elements: a plastic rod and a steel rod. The first stage of work is to get rid of the plastic body, leaving only the second, more durable one.

- Putting the spare part from the main piece of office furniture to one side, pick up a metal rod with a diameter of 8 mm. Fix the part in a vise so that a piece of about 6 cm remains on top.

- Pull the prepared cylinder onto this rod and push as hard as possible so that all the air comes out of the latter.

- Cut off the tapered portion of the cylinder and press the steel rod through the hole. Be careful not to damage the smooth surface and rubber band.

- At the end of the stem, it is necessary to make a thread that will fit the M8 nut.

- The extruded liner can now be put back in place with care to protect the aluminum piston.

- Insert the steel rod into the inner sleeve and pull it out from the back of the cylinder.

- To prevent the piston from sliding out, not falling into the cylinder during operation, screw an M8 nut onto the prepared thread.

- Insert the aluminum piston into the valve seat. Weld a steel tube to the cut end of the cylinder.

- Attach the resulting mechanism to the window control unit.

- Let all the air out of the system and fill it with oil (you can use machine oil).

The thermal actuator for the greenhouse made of office chair parts is ready to use. It remains only to test the device in practice and use it.

Of course, making such structures with your own hands is a very laborious process. But the result of hard work and attentiveness will surpass all expectations.

Another handy tool for creating an automatic greenhouse ventilation system is a conventional car shock absorber. The main active ingredient here will also be engine oil, which reacts very subtly to minor changes in temperature, which drives the entire mechanism.

The thermal drive for the greenhouse from the shock absorber is performed in a specific sequence.

- Prepare the necessary materials: a gas spring of a car shock absorber, two taps, a metal tube.

- Near the window, the opening and closing of which is planned to be automated, install the shock absorber rod.

- The third step is to prepare the lube pipe. Connect a valve to one end of the pipe for the flow of machine fluid, to the other - the same structure, but to drain it and change the pressure in the system.

- Cut the bottom of the gas spring and connect it to the oil pipe.

The thermal actuator from the automotive shock absorber parts is ready for operation. Monitor the oil level in the tube to avoid system malfunction.

After talking with professionals, rummaging through your unnecessary parts in the garage or shed, you will find a large number of necessary parts to create your own design of thermal actuators. If the installation of finished products is done as quickly and simply as possible, then even making your own mechanism with a door closer or lock will not be difficult for you.

After putting the system into action, it is necessary to take care of it so that it also justifies its peculiarity in terms of the durability of the mechanism.

Tips for use and care

Thermal drives for greenhouses are very easy to maintain. They need periodic lubrication of the driving elements, control of the liquid level, changes in the physical parameters of which drives automatic systems.

Also, if you do not plan to use the greenhouse in the winter season, experts recommend removing thermal actuators from windows and doors in order to extend their service life.

Reviews

Today the market offers a wide selection of domestic thermal drives for greenhouses. Reviews about them are mixed. Some buyers complain about the high cost of an automatic opener of a simple design (about 2,000 rubles apiece).

Among the advantages, consumers highlight, of course, the automation of the process of ventilating the greenhouse structure, but at the same time, they rejoice at the possibility of manually opening / closing the greenhouse if necessary.

There are few reviews about the installation of thermal drives. So, for example, buyers focus on the fact that a site is required to install most of them on the greenhouse wall. That is, a standard polycarbonate "wall" is not able to withstand one of the parts of the thermal actuator. To do this, it must be reinforced, for example, with a plywood sheet, a board or a galvanized profile.

For the rest, modern farmers are happy with such a purchase and happily share their impressions of the mechanism that automated their efforts to grow high-quality agricultural plants.

How to make a thermal actuator for a greenhouse with your own hands, see the video below.

The comment was sent successfully.