Greenhouse size: what influences the choice?

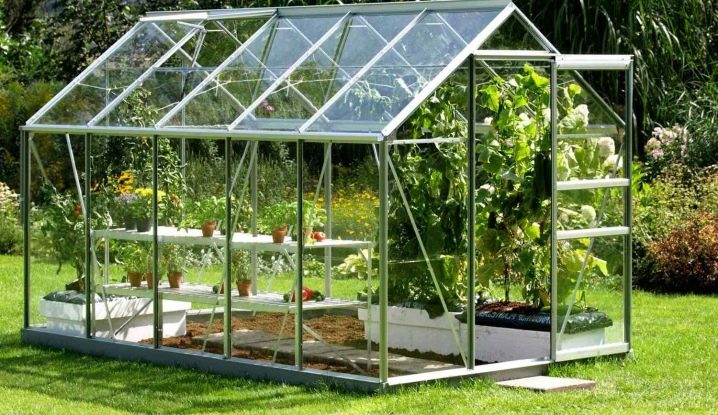

For summer residents in most of Russia, the use of greenhouses is a forced measure. Weather and climatic conditions do not allow growing heat-loving vegetables in the open field. Under these circumstances, a good harvest of peppers, eggplants and tomatoes can only be obtained in greenhouses. Greenhouses vary in size. But before building a structure on a site, it is important to figure out what affects the choice of a particular size.

Features and selection criteria

For personal plots, greenhouses are selected according to two criteria. First of all, the needs of the family are taken into account. For large families, an oversized greenhouse, for example, 8 meters long, is suitable. The requests of a family of two will be satisfied by a shorter structure - 4 m.

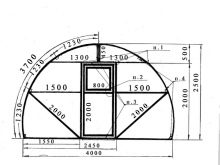

As for the width, it should be chosen not arbitrary, but quite definite. The width of the greenhouse should be such that it was possible to equip both beds and paths in it. If your choice falls on a structure 2 meters wide, then the aisle will pass in the center, and beds will be located on both sides of it. The maximum bed width should be comfortable for weeding and loosening. As a rule, eighty centimeters is sufficient.

In a greenhouse with a width of 3 meters, it is advisable to make three beds and two aisles. The distance between adjacent beds should allow free movement with watering cans, if stationary irrigation is not equipped. In addition, it is worth considering that you will not only have to walk between the plants, but also squat and bend over to loosen the ground, weed weeds and collect ripe fruits.

The second criterion is free space. For a greenhouse, not just a plot, for example, 3 by 6 meters, is suitable, but a place where:

- there are no fruit trees nearby;

- the long sides of the structure will face south and north;

- the shadow from the house (garage or other tall buildings) will not fall on the greenhouse;

- it is convenient to bring (bring up) water and fertilizers;

- the greenhouse will not disturb the neighbors.

The place must be chosen in advance. If, when marking the territory, for example, there is a free space under a four-meter structure, do not leave it empty. Better buy a greenhouse 5 m long, and plant in it not only peppers and tomatoes, but a few more eggplant bushes. And remember that the greenhouse must be set up so that the plants in it receive the maximum amount of sunlight.

The choice of length also depends on the method of planting the plants. When it is planned to grow not on ridges, but in special pallets or on racks, the parameters of the greenhouse already depend on the available trays and pallets.

The height is chosen depending on the height of the plants and the height of the users. A person should be comfortable inside the structure. In household structures, as a rule, a height of 2.0 - 2.5 m is sufficient. Industrial greenhouses have different dimensions.

Standard and optimal parameters

Greenhouses are produced as standard and to order. In principle, the structure can be sized to any size. However, the choice offered by manufacturers is so great, so you can always find the right dimensions. So, for the industrial production of agricultural products, greenhouses of large sizes with a usable area of several hectares are produced.

Small farms prefer to install several medium-sized greenhouses, for example, 100 sq. m.These types are standard, they have parameters: 20 m long and 5 m wide. There are rectangular models measuring 50 by 10 meters.

Household structures differ in that their dimensions are more compact. In a small area, you can install a standard greenhouse with parameters of 3x4 meters. As a rule, such a design has a wide doorway, allowing you to enter inside with inventory without any problems. There are two vents for ventilation. In longer models - 3x6 m, there may be more vents.

If short greenhouses usually have one door, then structures with parameters 4x6 and 6x3 are equipped with two doors at both ends. In this case, the entrances are with one or two leaves. Single-leaf doors are installed in arched greenhouses. Double-leaf entrances are sometimes found on wide gable models that look like a house. The more attractive a greenhouse looks, the more expensive it is.

Relationship with components

The shapes of greenhouses, to a large extent, depend on the material from which they are mounted. The greatest value is accounted for by the cladding material.

It is known that the walls and roof must transmit light well and reliably protect plants from rain, wind, hail and cold. The first requirement is within the power of glass, plastic wrap and polycarbonate.

Glass is expensive. The installation of glass greenhouses is quite problematic compared to other types of coverings. In addition, the disadvantage of glass is its fragility. Glass can be damaged during spring tillage. It is not insured against destruction by the blows of a large hail.

Glazing is carried out on a metal or wooden frame. Fastening requires additional effort and materials.

It is more convenient to attach the film to a wooden base. Polyethylene is inexpensive, but it does not differ in durability either. All the material is capable of is service for one summer cottage season.

The film shelter cannot be called reliable due to its instability to mechanical stress. Any scratch can damage the delicate material. Under the influence of ultraviolet radiation, changes in temperature and humidity, the film loses its elasticity. A strong wind can pull it out of its attachment point. Torn coating can be restored only for a short time.

The most suitable material for greenhouse cladding today is polycarbonate.

He has undeniable advantages:

- light weight;

- ease of installation;

- resistance to sunlight;

- transparency;

- relative strength;

- durability;

- democratic price.

Polycarbonate greenhouses retain heat well. Due to the fact that polycarbonate sheets bend well, they are ideal for greenhouses with an arch roof.

Arched structures are recognized as the most practical. Rainwater does not accumulate on the surface of greenhouses. Contamination is easily washed off. The cellular structure does not collapse under the influence of atmospheric precipitation, it is not afraid of frost.

Fast assembly of the structure is ensured by the large sizes of standard sheets (2.1 x 6 or 2.1 x 12 meters). The thickness of the sheets for greenhouses is 6 - 8 mm. The minimum number of joints reduces sealing work. Despite the large size, the sheets are easy to transport, as they easily roll into a roll. Polycarbonate is cut with an ordinary knife.

Frame material and foundation

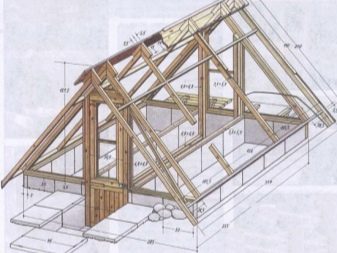

The durability and strength of the product depends on the material of the frame. The main initial components for the frame of greenhouses are wood and metal.

Wood has been used as a building material since ancient times. They have not given up on it in our days.

Wooden products have a lot of advantages:

- ecological cleanliness;

- low cost;

- ease of processing;

- light weight and ease of installation.

The disadvantage of wood is its susceptibility to rotting at high humidity. The frame has to be regularly treated with antiseptic agents.But even at the same time, the wooden frame will last for several years.

Greenhouses with one or two slopes are made of wood. It is possible to make a roof in the form of an arch, but the costs will be unjustified, therefore other materials are used for a semicircular roof.

Greenhouses are often built from metal. The frames are very durable, capable of withstanding heavy loads. The service life of metal frames significantly exceeds their wooden counterparts.

Supports are usually made of lightweight aluminum pipes. True, non-ferrous metal is more expensive than, for example, a galvanized steel profile.

The pipes are easy to bend, give them the shape of an arch. Aluminum, unlike steel, does not require painting or other surface treatment. It does not rust, does not rot, is resistant to temperature changes, and does not collapse under the sun's rays.

In addition to the relatively high cost, aluminum has another drawback - poor weldability. It will not be possible to perform welding work at home. Ready-made designs of standard sizes are on sale. If you are satisfied with the dimensions, then this is the best option.

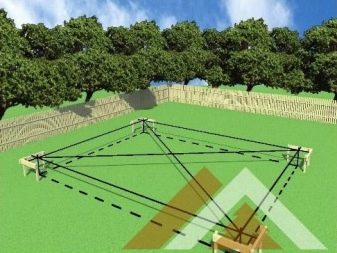

The greenhouse is a light structure. Despite this, she still needs a foundation. A greenhouse without a good foundation will not be able to stay in place under strong gusts of wind. The foundation also allows for better heat storage inside the building.

A solid base will extend the life of the entire structure. Perhaps the most suitable option would be a shallow strip foundation. You cannot do without a capital foundation when using greenhouses all year round.

If the greenhouse is designed for growing vegetables in the summer, you can get by with a more simple option - superficial.

The materials for the foundation are:

- concrete pouring;

- reinforced concrete blocks;

- Red brick;

- wooden beams treated with a decay agent.

The choice of material affects the appearance of the greenhouse, the comfort of the plants, the quality and quantity of the crop. The material must be selected taking into account the type of coating. For example, glass requires a more rigid foundation than polycarbonate.

Greenhouse shape

The shape of greenhouses differs in:

- height;

- the form of the base;

- view of the roof.

The height of the structure depends on the "growth" of the crops grown. Width and length - from the needs of the owner of the site and territorial possibilities.

The most popular is the arch-type greenhouse. The design allows you to grow both low-growing and tall plants. It is assembled from separate sections. By adding or subtracting sections, the length of the structure is adjusted. Ideal for polycarbonate.

Greenhouses with a pitched roof are usually attached to some kind of capital structure. They are located either on the south or west side of the building in order to stay in the area of direct sunlight for as long as possible.

Cover the attached greenhouses with glass, as it transmits light better than other materials. For growing seedlings of flower and vegetable crops, models with a pitched roof are used.

Gable models are more common than single-pitch models. Place structures in an open space. The coating can be film, glass, and polycarbonate. A variety of a gable greenhouse is a Dutch one. Its difference from the classic gable is that the sidewalls do not stand vertically, but obliquely.

Pyramidal and tent greenhouses are rare. Both types are compact, installed in small areas. You can grow seedlings, herbs, flowers in such structures.

Polycarbonate greenhouse installation

Before installing the greenhouse, you need to prepare and mark the site. On the territory allocated for the construction, pegs are placed in size. A trench should be dug around the perimeter of the future greenhouse. The bottom of the trench should be leveled and trampled down, and the horizontal level should be checked with a building level. Only small differences are allowed.

Otherwise, the building is threatened with distortions, which is highly undesirable. Leveling has to be done by adding sand (earth) or laying bricks, and this requires additional time and physical effort.

The foundation is laid out or poured along the trench. The role of the foundation can be played by a wooden beam laid on a gravel-sand cushion or brick supports. It would be useful to install old flat slate along the outer edge of the trench. It will prevent the penetration of weeds into cultivated plants.

All purchased greenhouses are supplied with assembly instructions. If you follow the manufacturer's instructions, focusing on the drawing, it is not difficult to assemble a greenhouse. For work, you will need the simplest tool and assistant.

In a simplified form, the assembly consists of:

- arrangement of the foundation;

- assembling the lower trim and fixing it to the base;

- exposing racks-arches;

- fastening racks;

- cutting and fixing polycarbonate along the ends of the greenhouse to the frame (including making cuts for doors and vents);

- installation and fixing of end parts;

- covering arches with polycarbonate sheets;

- fixing polycarbonate sheets to arcs with metal brackets.

The greenhouse is completely ready in a few hours. All that remains is to dig up the ridges and plant the grown seedlings.

For information on how to choose a greenhouse, see the next video.

The comment was sent successfully.