Greenhouse film: how to choose?

Greenhouse film is the simplest and most affordable option that allows you to provide optimal conditions for growing seedlings and vegetables on the site. Below is a detailed guide on how to choose the right film, and also discusses the features of each type.

Peculiarities

Film for greenhouses has many features that make the product the most popular among summer residents and owners of suburban areas. The material has a high wind load of 34 m / s. The greenhouse film can be used at temperatures from –50 to +60 degrees. The light transmittance index is 77%. These distinctive features make the product virtually universal.

Polyethylene is fused with fiberglass mesh, which increases the strength of the products. If you make a hole in the film, it will not creep, and the degree of damage will be minimal. Some canvases contain special fasteners with a rubber ring. When choosing such products, you do not need to make cuts.

Reinforced canvas has a complex composition, which consists of three layers. The first level is a reinforced frame, the rest of the layers are presented in the form of light stabilizing fabrics. The entire load is distributed over the fiberglass mesh. Due to this structure, the products are distinguished by a high degree of strength.

The disadvantage of the reinforced material is the low level of light transmission. It is 12% lower than traditional film.

Previously, only polyethylene sheets were used for greenhouses. At the moment, the market for greenhouse products is developing and improved analogues are offered to summer residents that have less pronounced disadvantages. However, all types of films have identical advantages and disadvantages.

Greenhouse film has the following advantages:

- affordable cost. Each type has its own price category, but if we compare it with glass or polycarbonate products, the film remains the most budgetary option;

- high level of elasticity and plasticity. Thanks to these qualities, you can create greenhouses of any shape;

- moisture resistance;

- a high degree of light transmission, along with the ability to scatter sunlight;

- light weight;

- easy installation.

The main disadvantages include the following nuances:

- short service life. When choosing a plastic wrap, you should be prepared for the fact that the purchase of a new product will be required for the next season. More expensive items are enough for 2-3 seasons;

- low degree of resistance to sun rays. This leads to rapid wear of the film. In some cases, this indicator is not so pronounced;

- Condensation forms on the surface of the material, which can harm many crops. This defect can be eliminated with the help of a hydrophilic film, which is made with the addition of special components;

- the ability to accumulate electrostatic charge leads to the attraction of dust, which reduces the transparency of the material. Manufacturers are trying to deal with the disadvantage by adding special components.

From many summer residents, you can hear that the greenhouse canvas is subject to sagging and stretching, so it must be constantly tightened. However, the presence of such negative characteristics does not reduce the popularity of the material.

Film is the cheapest product for arranging greenhouses, so many agree that it is more profitable to replace the coating once a year than to buy expensive material right away.

Views

There are several varieties of greenhouse film that you should familiarize yourself with before purchasing. Each of the types has its own characteristics and characteristics, on the basis of which each summer resident will be able to make the right choice. There are zipper types that are easy to use.

Polyethylene

Polyethylene sheets for greenhouses are sold in rolls. You can buy products with a width of 1.2 to 3 meters. There are options from one layer and two-layer, the sleeve of which is cut along the fold line.

When cutting a polyethylene sleeve, you will need to tape the fold with tape to extend the life of the material.

The best option for a greenhouse is products with a thickness of 0.1 mm to 0.15 mm. Thicker options have a long service life, but will not work for next year.

Polyethylene film is considered the cheapest and most popular material, but when it comes into contact with atmospheric phenomena, it quickly wears out and loses all its characteristics. Such a purchase would be the best option for arranging a small greenhouse in a summer cottage or suburban area.

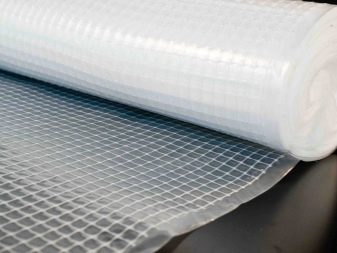

Reinforced

The reinforced type of film is a modified version of polyethylene. Oilcloth has a special frame with a mesh thickness of 8-12 mm. The frame takes all the loads on itself, distributing them over the entire surface.

It is recommended to choose a film by density. This is due to the fact that the thickness of the material can be different: it will be thicker on the reinforcement than in the central part. For growing seedlings, a product with a density of 120-200 g per square meter is suitable.

The reinforcing frame can be made from various raw materials:

- polyethylene with special treatment. There are twisted, stretched, low pressure and monofilament options;

- polypropylene;

- fiberglass;

On sale there is a special grade of breathable reinforced film, in which there are microscopic holes in the central part of the cells.

Fiberglass frame is a rare type of product, which is practically not used on the territory of Russia. Manufacturers claim that reinforced structures must last at least three years. The degree of wear depends on the climate of the region in which the products are used. The harsher the conditions, the faster the products will wear out. Therefore, the climatic conditions in which the film will be used should be taken into account before purchasing.

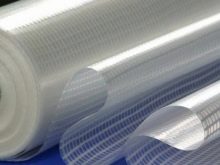

Pvc

PVC films have sufficient thickness and do not rustle, as many believe. Outwardly, it is similar to the material used to make a medical dropper. This similarity is not accidental, since the same material is used in both cases.

PVC oilcloth has optimal properties for use:

- the translucency reaches 90%. This indicator indicates that the product transmits light at the maximum level, which saves on the arrangement of auxiliary light;

- PVC almost does not transmit infrared rays into the greenhouse. Only 10% of the radiation gets inside;

- the transmission of UV rays is 80%.

Many users are discouraged by the high cost of products and poor frost resistance. The material is able to withstand temperatures up to -15 degrees. Despite the presence of significant disadvantages, the service life of the film is about three years with proper use.In regions with mild climates, the service life is extended to seven years

Stretch

The product is produced in rolls weighing several kilograms. The material is in great demand as it has a more favorable cost compared to other greenhouse films.

The products are of high quality. Even if the material is left in the open air for several years, it will not lose its strength indicators. Traditional polyethylene canvases will begin to tear after a year from small loads, and will crumble in the future. Stretch film is considered warmer, since it can be wound in several layers on the bars. No fastening is required for this material. It simply wraps around a frame or racks.

Manufacturers are constantly working on improving greenhouse films and releasing modified versions. Long-term products are in demand, which are divided into several categories, depending on the type of additives.

Perennial films are made mainly of polyethylene, sometimes you can find products that contain other polymers.

There is no specific list of characteristics, as they depend on the list of ingredients.

- Light stabilized. Such a film is highly resistant to sunlight;

- Hydrophilic. The products have a special layer that prevents the formation of condensation on the surface;

- Heat-retaining. The film transmits a minimum amount of infrared rays into the greenhouse;

- Anti-static film is dust-repellent;

- Reflective sheeting can increase the amount of light required to grow seedlings. There are options in black that allow you to control weeds;

- Light scattering. There are several types of such films, which differ in additives. You can choose material with phosphors, with UV absorption, with infrared reflection function.

Perennial films can combine several properties at once. On sale there is an option of five layers, which combines all the unique properties: the first layer is assigned high strength indicators, the second layer is responsible for blocking ultraviolet radiation, the third layer is responsible for light scattering, 4 is the regulation of thermal and infrared radiation. The fifth layer eliminates the formation of condensation on the surface of the film.

Air bubble

Bubble wrap is considered a perennial material.

It consists of three layers:

- the first two layers are made of polyethylene;

- the inner layer is vesicular. He is responsible for reinforcement.

Many users are familiar with such a film, calling it "anti-stress". Most people are attracted by the opportunity to click the product for their own comfort. Thanks to the stabilizing additives, the service life of the products is about 3 years. The term is determined for the film that is not removed from the frame of the greenhouses.

Thanks to the air inside the bubbles, the material retains heat and can be used for winter greenhouses.

Specifications and Description

Thickness and density have an impact on resistance to negative environmental factors. If we talk about a standard polyethylene film, its thickness does not affect the duration of operation, but in the case of using stabilized raw materials, the thickness indicator is of great importance.

Not everyone can visually distinguish a film with a thickness of 100 microns from 200 microns. Sellers know about this and often use it. To exclude mistakes when choosing, it should be borne in mind that thicker films weigh more. One running meter of 200 micron film weighs 530 grams. Products in 150 microns weigh 400 grams, 100 microns - 260 grams. For a greenhouse, a material with a thickness of 150-200 microns is suitable.

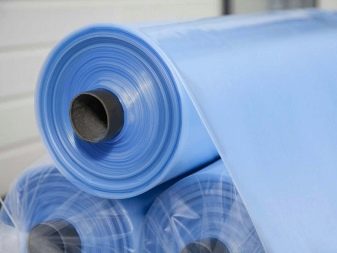

Product color may vary. Transparent film is suitable for greenhouses, as it allows more light to pass through. To get a material of a different color, manufacturers add food colors that fade under the sun. For this reason, it is not recommended to overpay for color options.

Choose the size that suits your greenhouse. Please note that the width and length of the rolls may vary.

Manufacturers overview

Before buying a film, you should study the list of manufacturers, familiarize yourself with their offers and material characteristics. It is recommended to look at customer reviews about the material, since comments from real users can tell a lot about the quality of the proposed product. Choose a film from trusted manufacturers that have been on the market for a long time and have shown themselves as a reliable brand.

The film of several manufacturers is of sufficient quality.

- NPF "Shar". It is a domestic trade mark located in the cultural capital of Russia. The manufacturer has been producing films for over 25 years and offers its audience composite polymer raw materials. The durable films "Svetlitsa", "Rostok" and "Yuzhanka" are in demand. The company uses its own formulas in the manufacture, due to which the service life of the "Svetlitsa" is about seven years. Customers respect this brand because it has high performance and lives up to the brand's promises;

- "Agrokhoztorg" is considered a leading enterprise in the production of polymeric materials. The manufacturer offers its audience a wide range and produces a special reinforced greenhouse film. Users often purchase products of this brand and consider it to be one of the best;

- "Agrotema A" has been on the market for 25 years. The brand produces polyethylene films for various industries. For greenhouses, we offer a standard polyethylene film and reinforced versions. According to users, the manufacturer offers products that justify their cost;

- "Stable" manufactures its products under the Stabilen brand. The manufacturer is known not only in Russia, but also in other neighboring countries. Films have a long service life and can be used in any climatic zone. The brand has several types of films, for some varieties the manufacturer offers covers;

- Odyssey company known since 2005. She is engaged in the production of plastic and reinforced films for greenhouses. Different products are available to customers, which differ in thickness and width;

- "Polymer" - this is the best manufacturer in the opinion of buyers. Production facilities are located in Kemerovo. The brand has been on the market for over 30 years. A wide assortment is available to consumers, which is constantly updated;

- "OPA" Is a St. Petersburg manufacturer, whose production facilities are equipped with modern imported equipment. The company produces quality products under the Polisvetan and Antiplesen brands. Buyers leave positive comments about the high quality of products and affordable prices;

- Richel Serres de France Is a French manufacturer that offers comprehensive options for solving the issue of arranging greenhouses. In Russia, the brand is represented by the Greenhouse Technologies company. Customer reviews indicate that the products do an excellent job of their duties even in the winter season.

Many people mistrust the Chinese film. However, most manufacturers offer quality products that are in no way inferior in quality to domestic brands. China is the best option for summer residents who want to get quality material at an affordable price.

How to choose?

To select the film that will best suit your greenhouse, experts recommend using expert recommendations. Experts advise choosing material based on functionality.

If you need a film for the equipment of a small greenhouse where you plan to grow seedlings, you should choose budget options, which include a standard film. A small amount is required to purchase such a product. Next year, you will need to buy a new film for the seedlings.

If you need a film for year-round use, you need to take into account the price category of the product and its characteristics. For such purposes, a film with a high degree of wear and agrotechnical properties is recommended.

Before buying, you should consider in which region the material will be used, as well as the features of the site. If the greenhouse will be located on a hill, and the area is exposed to frequent winds, it is recommended to choose more durable products. For a calm climatic zone or for plots that are in the lowlands, you can purchase medium-sized options for a suitable price category.

Each summer resident selects a suitable film, based on his individual preferences. Manufacturers are constantly working on the development of a greenhouse cover, so you can follow the news and experiment.

How to fix?

Fixing the film on the greenhouse is the second stage in the arrangement of the structure. The first step is to install the frame part. A frame made of wood or metal is suitable for work. After assembly, you can start preparing to stretch the film itself.

After that, you need to make calculations of the required amount of film, according to the dimensions of the greenhouse. In your calculations, you should take into account the fact that the roll coating will be overlapped. The joints will require 100–250 mm. To eliminate a shortage of products, it is necessary to add 10% to the selected quantity. That is, if the length of the greenhouse is 6 meters, you will need to add 60 cm to the measured value. Cut the film according to the marked dimensions. The pattern of the end pieces should be carried out with an increase of 250 mm for fastening.

The clamp can be created from the following material:

- wooden slats measuring 15 x 30 mm;

- strips made from old linoleum;

- special clips, which are a galvanized rail - a guide, 3 meters long., pre-fixed on the frame, after which you can pull the selected awning onto it and fix it with a plastic insert;

- cord, rope or elastic band;

- packaging tapes made of plastic;

- grids with large cells - is considered the optimal option for windy regions.

First, you need to cover the main structure with a film, after which you can proceed to fixing the material at the ends. Cover excess film with earth.

This option is suitable for attaching the film to a metal, plastic or wood frame.

How to glue the film?

To make gluing, you can use wooden slats, as well as screws and nails. The best option is a tape for packaging, fastened with staples. You can solder the film with a soldering iron or iron, glue it with special glue, sew with threads.

To solder the edges of the canvases, you need to put one layer on top of another and pass through the fluoroplastic film over the area with the soldering with a hot iron or a heated soldering iron. If there is no fluoroplastic film at hand, you can replace it with two narrow and even metal strips. To weld the canvases, you need to clamp the film between the iron parts and melt the protrusions on the edges 1 cm long. A blowtorch or spirit lamp is suitable for these purposes.

Bonding of a polyethylene film is possible with the well-known Moment glue. It is necessary in advance to degrease the top layer with a solvent. For polyamide products, PC-5 adhesive is suitable. After the seams are glued, they need to be ironed with an iron heated to 60 degrees.

Useful Tips

Competent installation and careful operation guarantee a long service life of the products and the preservation of their useful qualities.

It is possible to correctly fix the film on the surface of the frame and exclude damage to the material, guided by the recommendations from the pros.

- If installation is carried out on a wood frame, all components that will come into contact with the film should be sandwiched. The presence of defects will lead to punctures or tears in the material. It is important to remove all burrs, sharp edges and irregularities.

- The tree is treated with special antiseptics or paint. Before proceeding with the fastening of the film, it is recommended to dry the frame, since the solvents present can destroy the polyethylene.

- The metal frame should be sanded. Even the slightest hint of rust needs to be removed and the weld seams treated with a grinder.

- The fasteners should be positioned so that their protrusions do not come into contact with the film. If it is impossible to avoid contact, a polyethylene foam pad will save.

- You need to cover the frame of the greenhouse with a primer, after which you can start applying a light shade of paint. Dark objects quickly heat up in the sun, damaging the film.

- It will be useful to strengthen the skate and corners. In most cases, the film is wiped on these areas of the roof. This is because at these points it fits snugly against the frame. It is recommended to stick double-sided tape inside and outside on these areas. You will also need to glue the folds of the sleeves.

- The ends of the wire need to be insulated. This measure will eliminate damage to the film material. It is possible to carry out the installation of auxiliary rafters from wooden slats.

Care advice

To increase the life of the film, it is enough to observe the following recommendations:

- the products should be fixed at a temperature of 10-20 degrees Celsius, as well as in calm weather, in order to eliminate sagging;

- annual material is stretched a couple of days before planting;

- the use of self-tapping screws, nails and wire is not allowed;

- To remove dust or dirt, you need a regular garden hose, a soft sponge and a solution of laundry soap or dishwashing detergent.

All of the above guidelines show how to properly handle greenhouse film. Compliance with them will help extend the life of the products.

How to choose a film for greenhouses, see the video below.

The comment was sent successfully.