Choosing a greenhouse heating method

A high-quality greenhouse implies a combination of technical solutions, materials and structures that help keep sufficient heat inside. But in many cases (sharp frosts, especially delicate plants or the desire to get fresh vegetables and herbs in winter), this is not enough. You have to use different heating systems, each of which has strengths and weaknesses. They all deserve close scrutiny.

Features, pros and cons

A heated greenhouse allows you to lengthen the growing season of various crops, reduce the negative impact of the external environment. But in order to fully realize this task, it is required to choose the appropriate solution as clearly as possible, focusing on the area of the greenhouse, the area of its use and the number of possible costs.

To understand this, you will have to study all the major systems.

Solar

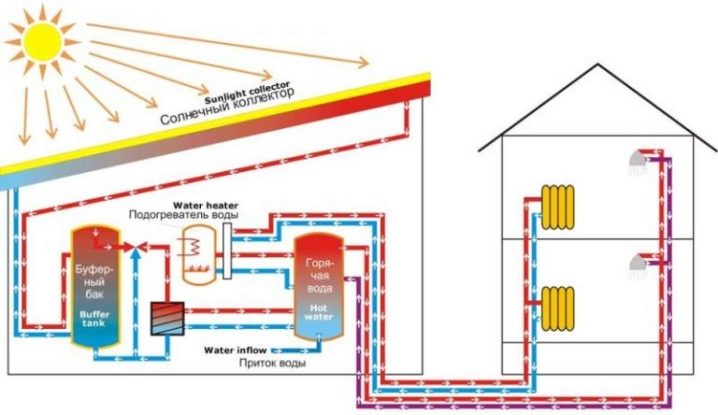

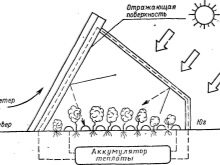

The most natural heating of a greenhouse involves the use of solar energy. Thanks to special technical solutions, this becomes possible even in the dark. A greenhouse heated by the sun should be made of polycarbonate, as this cellular material provides an increased greenhouse effect in comparison with other substances. An alternative is glass, which transmits over 95% of the luminous flux. The disadvantages of heating in this way are the need to create an arched structure, as well as strictly orient the greenhouse along the axis from east to west.

The problem with the lack of sunlight at night, as well as the shortening of daylight hours, are solved by equipping with a solar collector. These are trenches covered with insulation, covered from above with sand of a large fraction and covered with polyethylene and soil. The difficulty lies in the fact that even with the use of such peculiar batteries in winter, it will not be possible to achieve the optimal effect.

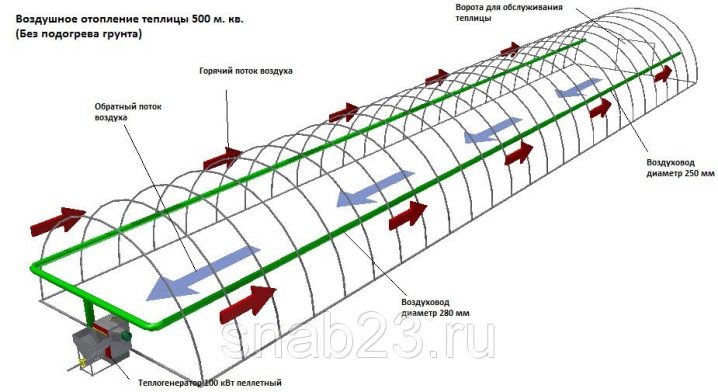

Air

With the help of air heating, when the air heated in the boiler enters the room, it is possible to raise the temperature by 20 degrees in 30 minutes. The high speed of work is due to the absence of auxiliary heat carriers, the level of heat transfer is high. But in areas with harsh winters, it is impractical to make such heating; you have to combine it with steam heating or in other ways.

Biofuels

For many centuries and even millennia, farmers have actively used manure and other organic substances to heat plants. The bottom line is simple: the chemical decomposition of biological materials leads to the release of a significant amount of heat. In most cases, horse manure is used, which can warm up to 70 degrees in 7 days and remain so hot for several months. If a very powerful heating is not needed, the manure is mixed with straw. Less powerful methods are the use of sawdust, tree bark and food waste.

The weak points are also obvious: it is not very pleasant to work with such substances, and if the winter is prolonged, even four months of warming up with horse manure may not be enough.

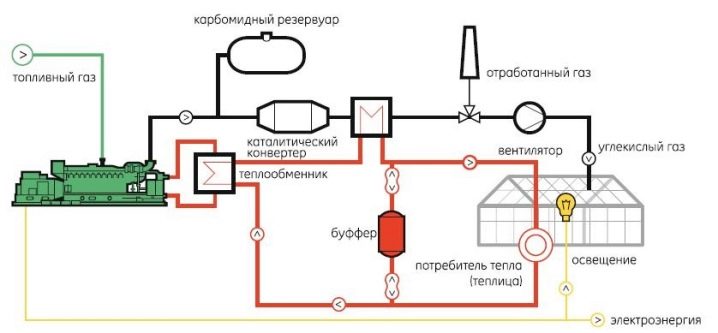

Gas

If a gas stove is installed in the garden house, it is logical to think about heating the greenhouse with cylinders or pipes. This is a convenient and practical solution, but it has a number of disadvantages.It will not be possible to create such a heating system with your own hands, it must be registered and proven safety to the gas authorities.

Burning natural gas leads to:

- waterlogging of the air in the greenhouse;

- an increase in the concentration of carbon dioxide;

- oxygen depletion of air.

Ventilation can compensate for these problems, but it is not as easy to create as it seems, and for a winter greenhouse, an excess of air entering from the outside negates the advantages of heating. In addition, heating large areas with natural gas is a rather expensive thing. The monorail heating option implies the formation of a primary ring that encircles the building around the perimeter and delivers heat from the source to the heating circuit. In fact, this is a large ring water pipe that is connected to a small circulation pump. When the water in the circuit cools down, the boilers transfer an additional heat impulse to it.

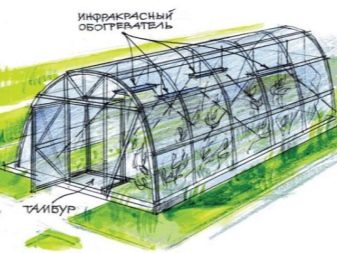

Electrical

Heating a greenhouse with electricity is quite efficient and does not require significant efforts from landowners. According to professionals, the best way to work is to use infrared heat sources, which do not waste energy on heating the air, directly transferring it to the soil and plants. The flip side of this solution is technical complexity, the inability to do everything properly without the help of qualified installers. But you can vary the heating in different parts of the room, creating the most attractive conditions for each group of crops.

Heating panels can generate heat using electricity or natural gas. Such devices can be mounted both under the ceiling and on the wall frame. It is advisable to use the electrical type of panels in greenhouses up to 25 sq. m. It is harder to warm up a larger greenhouse with its help. We'll have to lay a powerful line and consume a lot of current.

Gas-fired infrared radiators are more practical, but they have the same disadvantages as gas-fired boilers.

IR heating:

- uniform over the entire area;

- excludes overdrying of air;

- prevents the development of dangerous microorganisms;

- suppresses the spread of dust.

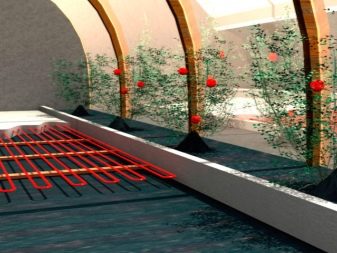

Foil greenhouses need to be heated more than those made of polycarbonate, because the heat loss in them is significantly higher. The heating cable is attractive in that it does not take up the usable area of the greenhouse. In fact, this is an analogue of underfloor heating in houses and apartments. With the help of the cable method, it is easy to give the soil the temperature required at a particular stage of growth: every gardener knows that sprouting and fruit production are different things. The cable can be laid without assistance, temperature control is very easy, and the current consumption is low. But you will have to install the cable system immediately, take into account its features when designing.

Carbon cord is more attractive than other cables in that it has zero thermal inertia, does not produce thermal surges, and provides a smooth change in conditions. It is compatible with any thermostats, and also allows you to create a circuit of any length or even change it.

An electric heat gun will allow you to warm up greenhouses without installing complex structures. The system can be put into operation only after purchase, by installing it on the ceiling so as not to damage the landings. The fan prevents air masses from accumulating under the ceiling. Along with electrical products, there are also diesel and methane-fueled products; some of the options are capable of working in a dusty room with excessive air humidity. Out of connection with the installed equipment, it is necessary to carefully calculate its characteristics and generate drawings (diagrams).

Benefits of water

Very often they try to heat a large greenhouse using water-type devices.It is necessary to study its characteristics, starting with the parameters of the heater.

Boiler selection

Heating by gas is considered by most users to be universal and economical; the automation maintains the temperature bar without human intervention. It is relatively inexpensive to heat the greenhouse in this way, and the flue gases are removed through coaxial chimneys (their outer layer is almost not heated).

Another affordable way to heat a greenhouse is a solid fuel boiler, various modifications of which can burn:

- firewood;

- coal;

- pellets.

The only problem is that it is very difficult to automate solid fuel installations, and without constant maintenance they will not fulfill their task. Liquid heating is very rarely practiced in gardening.

The undoubted advantages of electric water heating are:

- almost complete automation;

- compact size;

- the ability to vary day and night modes of operation;

- minimum noise level;

- high level of security (if everything is done correctly).

At the same time, electricity is quite expensive, and if the device is deformed or the insulation of the wires is damaged, there is a high risk of electric shock. When gas is supplied to the site, it is advisable to use it, regardless of the size of the installed greenhouse. If the greenhouse will be used year-round and its area exceeds 50 sq. m, it makes sense to use a solid fuel boiler. When using available firewood, the costs incurred will be reimbursed in 12-36 months.

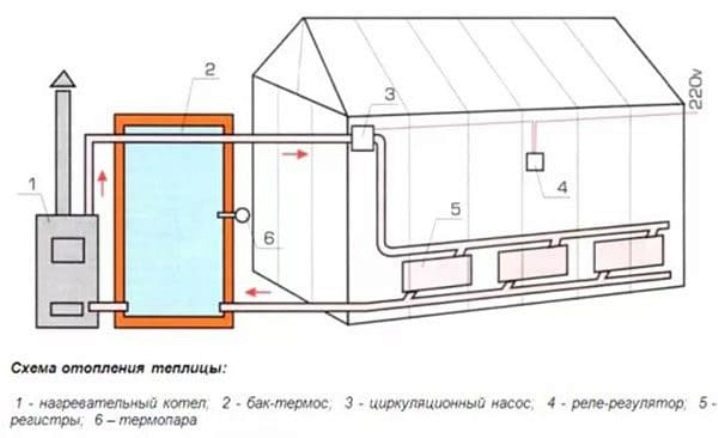

Device

The heating system circuit in the greenhouse can work correctly only if the number of working batteries is correctly calculated. For greenhouses below 3 m, they are guided by the area, the thermal power is determined by multiplying the area by 120. The calculated result is divided by the specific power of a single section to determine their total number. Radiators must be evenly spaced throughout the area. Ideal greenhouse batteries are very low, they will allow heating the air near the ground and the lower part of the trunks (shoots).

In addition to boiler systems and batteries, they use:

- pipelines;

- pumping devices;

- containers for liquid expansion;

- devices for mechanical water purification;

- balancing valves.

Several circuits can only be heated using distribution circuits. Solid fuel boilers are supplemented with heat accumulators.

System installation

Solid fuel heaters are placed in the vestibule or in a separate room. Appliances that burn gas or consume electricity can be delivered directly in a heated room. Floor installation is carried out on a lining of concrete or paving slabs, below they make a cushion of sand. Solid fuel and gas appliances must be connected to chimneys.

In the first case, a stainless steel sandwich chimney is recommended.

The installation of radiators is always wall-mounted; each battery must be supplemented with a Mayevsky tap and valves that open or block the access of liquid inside. Typical pipes have a diameter of 2 - 2.5 cm. If artificial circulation is provided in the heating system, it is advisable to install a cylindrical membrane tank for expansion, as tight as possible. You can install such a device at any convenient point, but most often in the area from the outlet from the boiler to the circulation pump.

A security group must be provided, including:

- pressure gauge;

- safety valve;

- air venting device;

- steel manifold;

- a coupling through which all other elements are connected to the main part of the system.

Such a group is mounted at the outlet where the water temperature is the highest. But the pump that provides circulation must be placed on the return pipeline. A coarse mechanical cleaner is required before the pumping unit.After assembly, the system is pressurized with air, which makes it possible to detect leaks in the system and installation defects. The check is carried out with soapy foam. When the pressure created by the compressor is equalized, bubbles must not appear at the joints and assemblies.

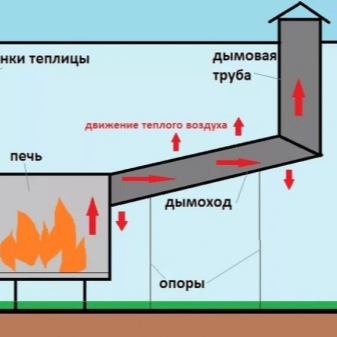

Stove

In addition to solid fuel boilers, there is another way to use solid fuel in greenhouses - these are various stoves made of metal or brick.

Advantages and disadvantages

Brick is more difficult to heat, but it also loses heat more slowly than steel. This makes it much easier to maintain a stable temperature in the greenhouse. A brick oven does not dry out the air, and its moisture is extremely important for plants. It is possible to compensate for the shortcomings of an iron stove by installing an additional circuit inside from registers or radiators.

Metal heating devices also have a strong side - they are preferable for greenhouses operating in spring and summer:

- such structures can be installed for a short time;

- no need for a complex foundation;

- the oven takes up relatively little space;

- the cost of the product is less than that of the brick version;

- all work can be performed without recourse to professionals.

Yes, a metal stove cannot be automated, but with constant care for the plantings during the growing season, this circumstance does not play a special role.

Furnace selection and installation

The chimney system for a metal stove must be installed at an angle of at least 15 degrees. This step increases the heating power. The pipe must be made of metal, it does not need to be insulated, except for the intersections with the roof or wall, since protective boxes are placed there. Before installing the stoves, you need to consider their stability - if the hearth overturns, the greenhouse can be damaged, and in the worst case, a fire will start.

There are many different designs, but the Vesuvius-mini stove is deservedly considered one of the best. This is a compact and cheap stove, the design of which is as simple as possible. With the help of a device, the thermal power of which is 4 kW, it is possible to warm a greenhouse with a total area of up to 25-30 sq. m. Inside the steel case, firewood is burned, and water can be heated from above. It is also permissible to use Vesuvius-mini as a stove.

"Cinderella" is also a compact device made of alloy resistant to strong heating. With the help of side convectors, the distribution of hot air is improved, the total heat output is 6 kW, the heated area can be up to 60 sq. m. The operation of the furnace is facilitated by a viewing window in the door, a hotplate is installed on top for warming water. Firewood or household waste is put into the stove.

The advantages of the "Normal" system are increased energy production (it warms up greenhouses with dimensions of 60-80 sq. M), as well as special protective covers that prevent the side walls from warming up to dangerous values. The designers took care of the reliable locking of the door to prevent smoke.

In turn, if you choose the Klondike NV-100 stove, you can provide a long-term supply of heat outside - up to 10 hours in a row. And those who want to heat the greenhouse with wood processing waste or cardboard should take a closer look at the “Breneran Aquaten” design. It is a gas generator furnace with a water circuit.

For your information: of course, no stoves work with waste oil. But heat guns may well use it.

Whatever the owners choose, it is required to prepare a solid foundation for which they lay tiles for sidewalks, bricks, or simply tamp the ground. The best place to install ovens is in the middle of the greenhouses, as this makes heating more uniform. If there is a solid wall, the back wall of the stove should be leaning against it.

The connection of chimneys to the flue pipes is done on the basis of heat-resistant sealants.

Criterias of choice

In principle, heating a greenhouse is possible using a variety of ovens and heaters, as long as the generated power makes it possible to create the desired temperature in a certain area. But if we are not talking about the "principle", but about the practical use of certain solutions, you need to think about completely different things. So, the best heating systems projects will be useless if their dimensions do not allow the use of a particular device in a particular room. The power of devices varies not only according to the area, but also according to the material - it has long been known that heat loss through polyethylene is higher than through polycarbonate.

The next important criterion is the amount of costs, and you should take into account both the costs of components, their installation, and subsequent use. Certain types of heaters are completely impractical in small greenhouses, others are installed at a minimal price, but during operation they consume a large amount of fuel or energy.

Steam heating is justified if it is possible to connect the greenhouse to the heating system of the house. It is advisable to insulate the pipes properly, and you will have to create a significant margin of boiler power. It is undesirable to use such a system when the distance from the dwelling to the greenhouse is more than 10 m. An autonomous steam heater can be installed in the greenhouse itself; water circulation is provided by special pumps.

In early spring, it is recommended to use solid fuel boilers and stoves.because they resist frost well. Boilers are better than stoves, because they do not require frequent addition of fuel, it is consumed very effectively. Solid fuel boilers should not be placed directly in the greenhouse, so as not to dry out the air, in extreme cases, you have to put humidifying agents nearby.

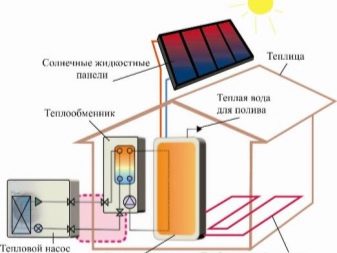

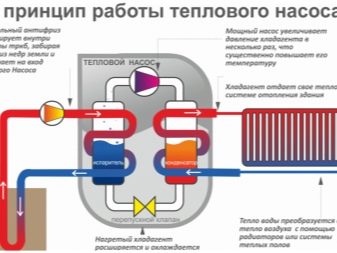

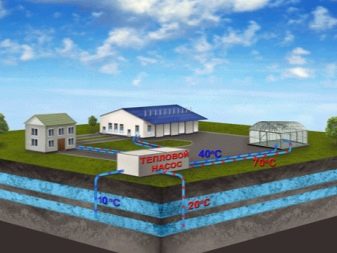

Geothermal heating in greenhouses is rarely practiced because heat pumps are expensive and difficult to install. It is advisable to create an integrated heating system that simultaneously heats up not only the greenhouse, but also the house. Important: heat pumps are needed for liquid soil heating systems, they are not able to supply water to radiators.

The solar battery is a vacuum tube that is laid in a glazed panel.

Water circulates through them, while it warms up quite strongly and enters a special line. Solar panels (or, in other words, photovoltaic panels) are not suitable for heating greenhouses because they are designed to generate electricity. It is advisable to use, along with collectors, gas boilers, stoves, heat pumps and other heating means to insure against the dark.

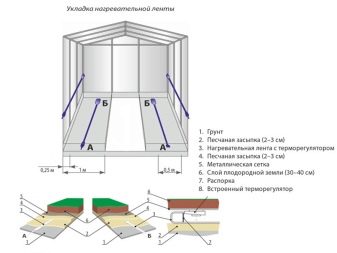

Thermal tape in the greenhouse is used quite often. In terms of composition, it is a glass thread, supplemented with a thermostat. Inside there are eight nichrome veins surrounded by water-impermeable rubber. The device works stably only in the temperature range from 15 to 20 degrees, which allows the current to be consumed only as needed. Each part of the plant heats up in the same way, the only alternative that can achieve the same effect is heating with manure. But tape is better than it just because it helps warm up the greenhouse in almost any weather, not just during the warmer months.

With the help of the tape, the death of plants is prevented in case of sudden frosts.

Quite often a lamp or even a row of lamps is used for heating purposes. Infrared heating of this type is directed from top to bottom and effectively acts on the whole plant, as well as warms up the soil layer. According to research data, such systems increase germination by 30-40%.

Which ones are popular?

If you pay attention to the most popular solutions in heating greenhouses, it is not difficult to understand that most often they try to do without electricity and without gas. After all, solid fuel heat sources are installed easier than others.Stoves according to the Buleryan system are considered the least convenient, since they cannot be dispensed with without regularly adding firewood by hand. If these difficulties are not frightening, the low cost of construction and efficient heating of the greenhouse space make this choice quite justified.

The second line in the rating of demand is occupied by three options at once:

- infrared devices;

- solar energy storage;

- means of cable heating.

All such options are installed cheaply and simply, they can work without constant human attention. But you have to come to terms with the increased cost of energy obtained by such methods - to use mineral fuel more economically.

The next position is occupied by heat guns and heat pumps.

Both types of equipment are easy to maintain, suitable for automatic heating. The problem is that they cannot be called economical and the purchase and installation costs are justified on average after 10 years.

Gas-fired rail heating pipelines are also in wide demand. Instead of a boiler, you can use burners or heaters placed around the perimeter. Such a device provides an even supply of heat.

Not everyone uses electric heating, but if the power supply is quite stable, and the greenhouse is planned to be used even in winter, such a step is deservedly considered effective. It is difficult to find other devices that would allow you to regulate the temperature with the same ease.

For information on how to make water heating in a greenhouse with your own hands, see the next video.

The comment was sent successfully.